The W58 transmission that comes behind the 2JZ in the Z30-chassis SC300 is not known for ruggedness. In the first outing with the new wiring, I grenaded 3rd gear quite well. Out came the W58 and in went an awesome Tremec T56 via a swap kit from Grannas Racing.

Don’t get me wrong, the T56 is an excellent transmission. It will likely outlast the rest of the car at the power levels I’m putting through it. The one thing that I hate about it, though, is that reverse and 5th are in the same place.

OK, well, they’re not EXACTLY in the same place. You have to push the shifter over farther to the right to get it into reverse. In almost all OEM applications, an electronic lockout solenoid prevents you from accidentally doing this. However, with a longer shift lever, it’s still possible to accidentally engage reverse (instead of 5th) because of the torque you can easily generate. This tiny little Hurst shift lever does the trick. Without powering up the reverse solenoid to disengage it, you really have to muscle the shifter to engage reverse.

I still really was not a fan of this design. Sure, it’s safer-ish with a shorty shift handle and the reverse solenoid. Wiring the reverse solenoid and remembering to turn it on and, more importantly, turn it OFF? That’s a pain. Maybe there’s something I could do to make this whole reversing thing easier.

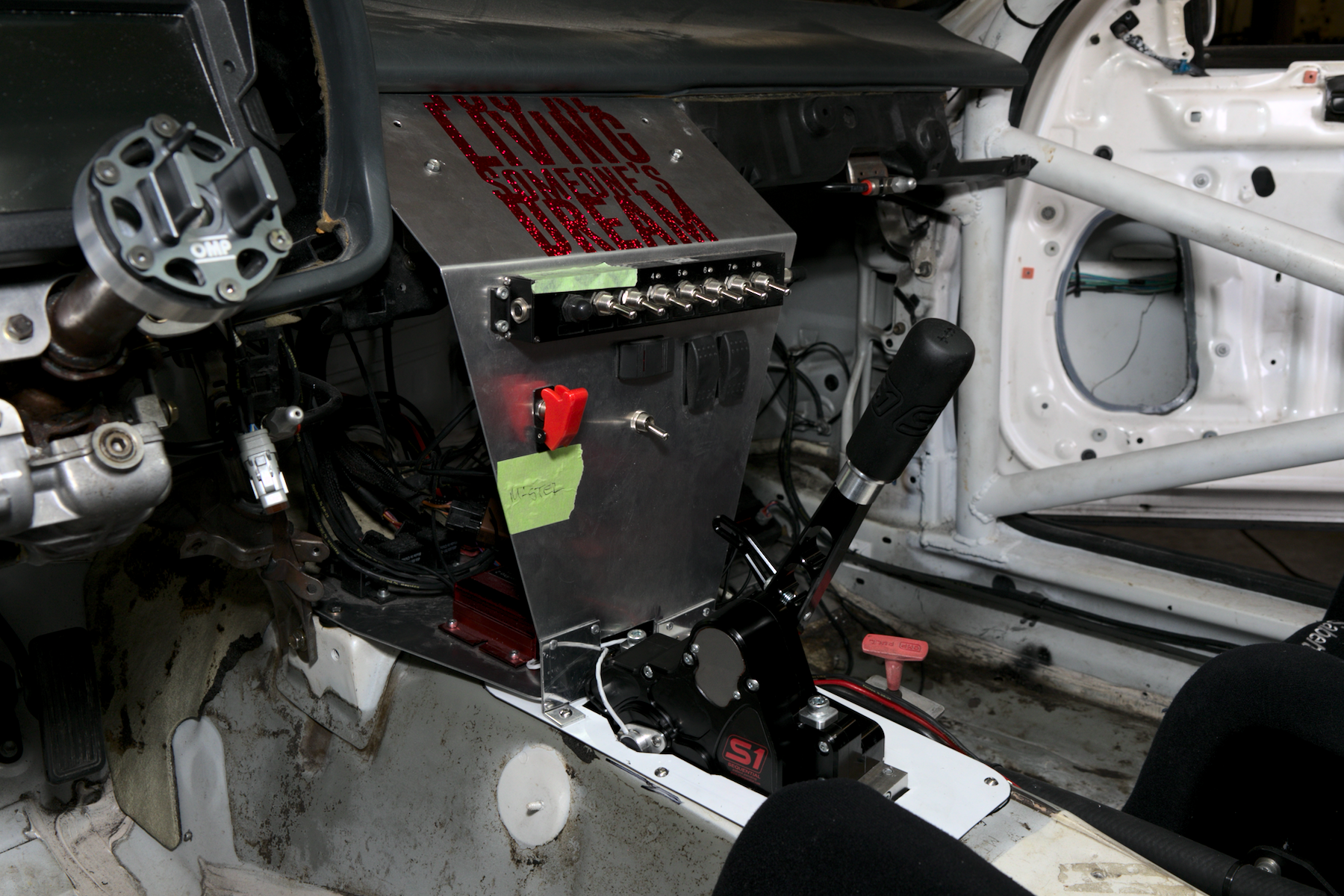

Australians are known for being a little… eclectic… when it comes to automobiles. The eclectic engineering wizards at S1 Sequential figured out how you can push forward and backward and somehow make the T56 go through all the gears, just like on a fancy sequential racing transmission. It’s also a predominantly bolt-on affair!

You may have seen me talk about it after having seen it at the 2019 PRI show. I liked it so much that I got one for myself.

As there are several versions of the T56 transmission, be sure that you figure out which particular version you have before ordering your adapter. Grannas Racing uses the Magnum version of the T56, so I ordered appropriately.

You can also make out the little gear position sensor hanging off the side. Since I have a fully programmable dash, I simply ordered the bare sensor. However, S1 also sells an LCD-segmented gauge that can be wired independently to show you the gear position – including reverse!

I guess you don’t really have to remove the shift handle, but it seemed convenient. It also made a nice photo op to show you that the S1 adapter is quite a lot bigger than the standard shifter. Cutting and drilling of the car would be required.

Not to give the end away at the beginning, but if you are considering a T56 swap and have not pulled the trigger yet, and you are considering the S1 Sequential, you should definitely just get the S1 sequential and then install that at the same time as your T56 swap. Trust me, it will make your life a fair bit easier.

But I don’t do things the easy way, so onwards and upwards, right?

12 comments

When will this car see some hard use and put all these bits to the test?

If you subscribe to my personal YouTube channel I’ll have video from Carolina Motorsports Park where I was beating it up a good bit. Even ended up mowing the lawn at some point! I ran 1:48 which is almost 9sec off the TT2 pace, but this is the first real experiment on the car and my first time at CMP in over a decade. I’ve got a lot to learn about the corner speed limits of the car. Looking at my data it’s basically “yeah just go faster everywhere”. Ha!

@clay There are now some videos on my YouTube: https://www.youtube.com/user/erikmjacobs

Awesome! Those shifters look like so much fun. The date on the vid os wrong? It says 2010. I will check out your You tube.

@erik yes the date was wrong. I can’t change it and YouTube got rid of annotations, so I just blurred it out.

I’ve driven that shifter before and you really can’t rush a shift with it. My friend wallered one out after a couple of race seasons and it began to miss gears, I think there’s a lot of leverage working against it. That and once worn, I think the housing grows with heat and makes it worse. I had the B&M and it sucked when it heated up. I love my new MGW and don’t see myself running anything else now.

I noticed that the shifter assembly was pretty warm after a session, but I’m also not running a transmission fluid cooler.

The MGW looks nice, but it’s a standard H-pattern and not a sequential. I didn’t really have any issue with the factory Tremec shifter, other than I really wanted a teeny tiny short handle. That Hurst handle I had was pretty good, but I would’ve liked something even shorter. The THROW wasn’t the problem. It was more the shift handle length.

We’ll see how the S1 holds up after time. My only issue with it is more user error than a problem with the shifter. For whatever reason, I tend not to push it forward enough, so I end up not fully engaging the next gear down. It’s not really a big deal — just something I need to work on or perhaps adjust the shifter angle a bit more.

The shifter sort of has 2 clunks to grab a gear, don’t let the first one fool you. It can be pretty convincing. I’ve found with the MGW that reverse is an asspain to grab, so if this doesn’t do it for you long term consider the MGW as an alternative to not grabbing reverse when you want 5th. I did that years ago to another T56 with a worn out stock shifter and reverse was never the same after that.

Great article, this Soarer content is always so interesting to read. Great vocab too, automotive project car stories can often fall into “catalogue details” faster than the wonders of gearbox black magic. 10/10

Thanks, Brad! I’m grateful to know that the effort I put in is appreciated!

is there a difference between a sequential trans and a sequential shift trans? reason I ask is because I had a chance to get an “ikeya sequential shifter” for cheap but a friend poo-pooed it saying that is not a real sequential trans –can anyone shed some light on the subject

Yes, and no, and kind of. Context matters.

In the case of the S1, Ikeya, and other adapters, you are attaching a sequential shifter assembly to an otherwise normal tranmission. So, while the activation of gears becomes sequential (you can only select the next or previous gear, “sequentially”), the clutch is still required in order to keep the other parts of the transmission happy (namely the synchronizers on the transmission gears).

A true sequential transmission usually has an internal construction that allows for changing gears without needing to disengage the engine from the transmission via the clutch. A true sequential transmission may use either a physical shift lever (like V8 Supercar a few years back, late 90s BTCC, old DTM, etc) or shift paddles on the steering wheel.

Sequential transmissions may, but don’t have to be, integrated into the engine management system to handle things like rev matching. They often still have a clutch for starting from a dead stop, but the clutch is not required for switching gears once moving.

Where it gets funky is in modern dual-clutch transmissions and automated manual transmissions. I think the Volkswagen-Audi group DSG may have been one of the first “passenger” units on the dual-clutch side, and BMW with the SMG on the E46 M3… maybe.

In the case of the dual-clutch unit, it is much like a regular manual inside, but there are two clutches and two input shafts and a computer that controls how things work. While the experience is sequential (use a paddle or push/pull on the shifter to get the next gear), there are still clutches and synchros inside. The BMW SMG more or less used a computer to actuate the regular single clutch. These systems may or may not have a clutch pedal at all, as the computers do all of the work, including starting from a dead stop.

I hope this helps!