Project STurdteen: Cooling, Bolt-Ons, and More

In Part 1 of Project STurdteen we discussed some of the future plans of the car as a purpose-built entry-level drift car that can be used for competitive purposes in ProAm. One of the big issues I experienced previously had to do primarily with heating and cooling issues. We decided to go with a complete Koyorad cooling system, which incudes a radiator and oil cooler. We also included a power steering cooler to address steering pumping up issues I had experienced in the past once the car would get hot, which is a common complaint in many drift cars.

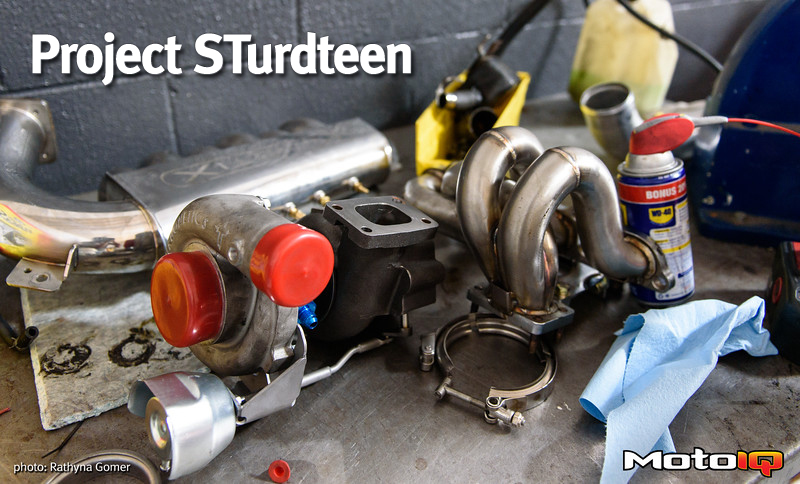

Power was another issue, the poor SR20DET could only muster around 170 something hp and a lot more would be needed for doing any sort of serious drifting. So it was time to get to work, dig inside and start the program to get more power going.

When power steering systems get hot, the pump cavitates and creates air bubbles. When bubbles hit the spool valve or get in the ram, this causes a momentary loss of steering assist. Losing power steering mid-drift is probably one of the sketchiest feelings, so I figured I'd work to resolve this issue ASAP.

When power steering systems get hot, the pump cavitates and creates air bubbles. When bubbles hit the spool valve or get in the ram, this causes a momentary loss of steering assist. Losing power steering mid-drift is probably one of the sketchiest feelings, so I figured I'd work to resolve this issue ASAP.To compound all of this, drift cars really heat the power steering up and put plenty of demand on it. This is due to the large amount of steering that has to get done and adjustments to caster, trail and steering axis inclination to get more self steer. Adding to these greatly increase the strain on the steering system.

We decided to go with a Koyorad 10-row universal bar and plate cooler to serve as the power steering cooler. The Koyorad coolers feature an oven braised bar and plate core which is much stronger and can take more pressure and abuse than cheaper soldered or sweged cores. The Koyorad cooler will be much more effective than the stock Nissan sections of aluminum tubes that are supposed to sorta cool the fluid.

Koyorad Oil Coolers incorporate -10 AN ORB (O-Ring Boss) provisions for the inlet and outlet allowing versatility. Users may easily reduce AN to AN, or convert from AN to Push-Loc style barb fittings for any needs. This is a great help when installing the cooler on different applications.

Koyorad Oil Coolers incorporate -10 AN ORB (O-Ring Boss) provisions for the inlet and outlet allowing versatility. Users may easily reduce AN to AN, or convert from AN to Push-Loc style barb fittings for any needs. This is a great help when installing the cooler on different applications.  This cooler in particular holds an additional 9 ounces of PS fluid as well. Every bit of increased oil volume can help in a limited capacity power steering system.

This cooler in particular holds an additional 9 ounces of PS fluid as well. Every bit of increased oil volume can help in a limited capacity power steering system. Leak free super reliable hose terminations are critical for any competition car. About 40% of all race car failures can be traced to faulty plumbing of critical fluids so we did not want to skimp here with our oil cooler.

Leak free super reliable hose terminations are critical for any competition car. About 40% of all race car failures can be traced to faulty plumbing of critical fluids so we did not want to skimp here with our oil cooler.We used Earl's AN fittings and hose for our oil system. AN fittings are super reliable aircraft based hose terminations with ends that cut into the hose rubber liner for a positive seal and wedging threaded nuts to clamp the hose in place on the fitting without weakening it.

Here we have two 60 degree -8AN fittings from Earl's to be used for our engine oil cooler. Earls fittings have twin seals for leak resistance and have the ability to swivel 360 degrees after installation of the hose. You want to try to avoid 90 degree fittings if possible due to pressure drop cause by tight bends.

Here's a 12 foot length -8 stainless steel hose that will be used for the oil cooler and eventually turbo drain lines as well.

Here's a 12 foot length -8 stainless steel hose that will be used for the oil cooler and eventually turbo drain lines as well.