,

Next, Howard took the valve cover off so he could prepare for the installation of the JWT C2 cams and valve springs.

Next, Howard took the valve cover off so he could prepare for the installation of the JWT C2 cams and valve springs. The first step is to remove the spark plugs. This is so compressed air could be blown into the cylinders to hold up the valves while the keepers were being removed when the valve springs were compressed.

The first step is to remove the spark plugs. This is so compressed air could be blown into the cylinders to hold up the valves while the keepers were being removed when the valve springs were compressed.  Next, is to remove the old valve springs. With the cylinders being pressurized, a spring compressor is used to push down on the retainer so the keepers can be removed with a magnet. Lacking a compressor, soft nylon rope can be fed into the cylinder via the sparkplug hole to hold the valves up as well.

Next, is to remove the old valve springs. With the cylinders being pressurized, a spring compressor is used to push down on the retainer so the keepers can be removed with a magnet. Lacking a compressor, soft nylon rope can be fed into the cylinder via the sparkplug hole to hold the valves up as well. Howard organizes the keepers, retainers and rocker arms to make sure all of the parts go back in exactly the same spot using a muffin tin. The new JWT valve springs go back in place of the stock parts and everything is reassembled in the reverse order it came apart.

Howard organizes the keepers, retainers and rocker arms to make sure all of the parts go back in exactly the same spot using a muffin tin. The new JWT valve springs go back in place of the stock parts and everything is reassembled in the reverse order it came apart. In goes the new cams from JWT. The valve shims and rocker arms are put back into the retainers, and the cams are set back down. The cam caps are carefully tightened a bit at a time in an X pattern to avoid breaking the hard chilled iron cam. This step is very important and must be done with care or the cams will crack! Once the cam caps are snug they are torqued down to their final tightness.

In goes the new cams from JWT. The valve shims and rocker arms are put back into the retainers, and the cams are set back down. The cam caps are carefully tightened a bit at a time in an X pattern to avoid breaking the hard chilled iron cam. This step is very important and must be done with care or the cams will crack! Once the cam caps are snug they are torqued down to their final tightness.  The test fitting was a very important process since the new ISR Performance tubular turbo manifold was significantly larger and took up more space than its OEM counterpart.

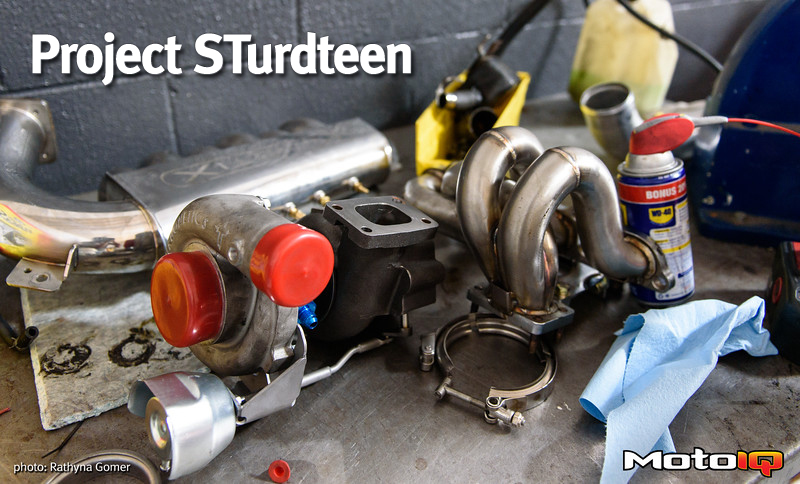

The test fitting was a very important process since the new ISR Performance tubular turbo manifold was significantly larger and took up more space than its OEM counterpart.