,

We removed the old fuel injectors to prepare for the new larger Deatschwerks ones going in. The Deatschwerks injectors drop in place of the stock parts. You simply remove the two Philips screws holding the injector retaining cap to the fuel rail, twist the stock injectors out and push the new injectors in, reinstalling the cap, it's that easy.

We removed the old fuel injectors to prepare for the new larger Deatschwerks ones going in. The Deatschwerks injectors drop in place of the stock parts. You simply remove the two Philips screws holding the injector retaining cap to the fuel rail, twist the stock injectors out and push the new injectors in, reinstalling the cap, it's that easy.  Next, Freddy the old Greddy intake manifold was bolted in place.

Next, Freddy the old Greddy intake manifold was bolted in place. We decided to go with HPS silicone hoses to finish up our cooling system. We also used HPS's non-cutting heavy duty stainless steel worm gear hose clamps. We eventually use their couplers for the intercooler piping setup. More on that later.

We decided to go with HPS silicone hoses to finish up our cooling system. We also used HPS's non-cutting heavy duty stainless steel worm gear hose clamps. We eventually use their couplers for the intercooler piping setup. More on that later. HPS hoses are made of temperature resistant silicone and can take up to 350 degrees. They are reinforced with 4 plys of tough polyester fabric. This is twice as many as your typical stock rubber hose. The silicone hose is much more resistant to oxidation and will last much longer than a stock rubber hose. HPS hoses have a red high temperature inner layer and a decorative top colored layer for looks.

HPS hoses are made of temperature resistant silicone and can take up to 350 degrees. They are reinforced with 4 plys of tough polyester fabric. This is twice as many as your typical stock rubber hose. The silicone hose is much more resistant to oxidation and will last much longer than a stock rubber hose. HPS hoses have a red high temperature inner layer and a decorative top colored layer for looks. Here is the top radiator hose installed. HPS hoses are molded into shape and built up on mandrels to ensure a correct drop in fit. We have used HPS hoses on most of our project cars and on many race applications and have yet to have anything even remotely close to a hose failure.

Here is the top radiator hose installed. HPS hoses are molded into shape and built up on mandrels to ensure a correct drop in fit. We have used HPS hoses on most of our project cars and on many race applications and have yet to have anything even remotely close to a hose failure.  Here is the bottom radiator hose installed. We used HPS hose clamps as they are designed to clamp more positively yet not cut into the soft silicone hose when tightened down securely in the way that cheap hose clamps can. The HPS clamps are also made of non corroding stainless steel. With a strong hose and positive clamps we can confidently increase our coolant pressure with our Koyo high pressure radiator cap knowing that we won't have a hose leak or blow off. I wish you guys could feel these hoses – just from touching them you can tell the difference in quality from the “cheap” hoses. It's worth upgrading!

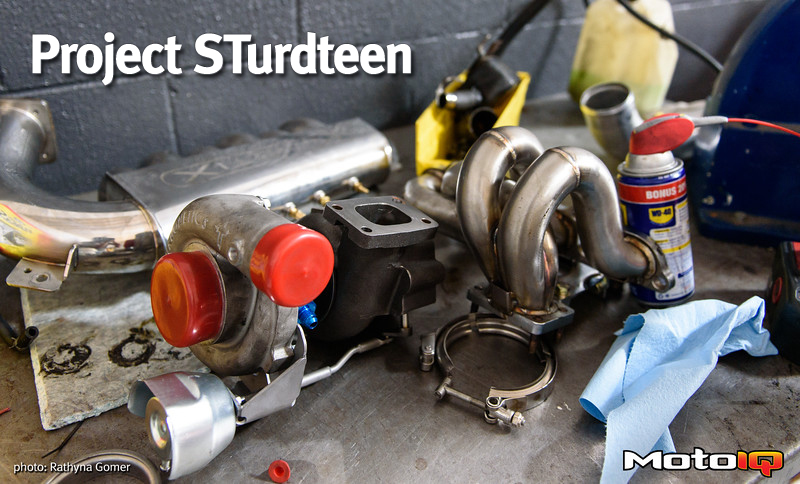

Here is the bottom radiator hose installed. We used HPS hose clamps as they are designed to clamp more positively yet not cut into the soft silicone hose when tightened down securely in the way that cheap hose clamps can. The HPS clamps are also made of non corroding stainless steel. With a strong hose and positive clamps we can confidently increase our coolant pressure with our Koyo high pressure radiator cap knowing that we won't have a hose leak or blow off. I wish you guys could feel these hoses – just from touching them you can tell the difference in quality from the “cheap” hoses. It's worth upgrading! Now all of our high performance parts are in place and we are ready to send our car to Eimer Engineering to get our charge pipes and exhaust system made from Burns Stainless tubing welded up.

Now all of our high performance parts are in place and we are ready to send our car to Eimer Engineering to get our charge pipes and exhaust system made from Burns Stainless tubing welded up.My project S13 is pretty much going through a major overhaul at this point, but we are working on developing each system within the car. One of the worst things as a driver is not having the confidence in your own car that it can get you through the weekend or be dependable for competition. It starts with looking at and improving all the “little” things. Stay tuned as we continue building this project into a solid, dependable drift car!

Sources: