,

Next the calipers and rear rotors are removed. While we were doing this we were shocked to discover that our pads were worn to the backing plates and our rotors were grooved and gouged. Talk about full metal brake pads. So that's what the squeaking was. The front brake pads and rotors were pretty worn as well. Surprisingly, the Big TRD brakes still worked pretty good. Duh, we better be more diligent on checking things in the future.

Next the calipers and rear rotors are removed. While we were doing this we were shocked to discover that our pads were worn to the backing plates and our rotors were grooved and gouged. Talk about full metal brake pads. So that's what the squeaking was. The front brake pads and rotors were pretty worn as well. Surprisingly, the Big TRD brakes still worked pretty good. Duh, we better be more diligent on checking things in the future. With the brakes and calipers out of the way the driveshaft is unbolted and all the bolts holding the diff to the axle housing are removed. A couple of nuts are left hand tight to keep the diff from falling out. Then the five bolts holding the axle bearing retainers are removed.

With the brakes and calipers out of the way the driveshaft is unbolted and all the bolts holding the diff to the axle housing are removed. A couple of nuts are left hand tight to keep the diff from falling out. Then the five bolts holding the axle bearing retainers are removed. Then the axle and parking brake with backing plate can be partially pulled out to free up the diff. At least the parking brake is still in good shape. You can leave the parking brake assembled and the cable attached, just one of the cable hold down brackets has to be unbolted. Drum type parking brakes are a bitch to reassemble so it's a good thing that this install doesn't require it.

Then the axle and parking brake with backing plate can be partially pulled out to free up the diff. At least the parking brake is still in good shape. You can leave the parking brake assembled and the cable attached, just one of the cable hold down brackets has to be unbolted. Drum type parking brakes are a bitch to reassemble so it's a good thing that this install doesn't require it. Remove the few hand tight nuts and the differential housing will drop free. This sucker is heavy so be careful. Be sure to drain the gear oil before you even start! Howard bolts the differential carrier to this cool diff assembly jig he made which allows him to lock just about any diff into a vice.

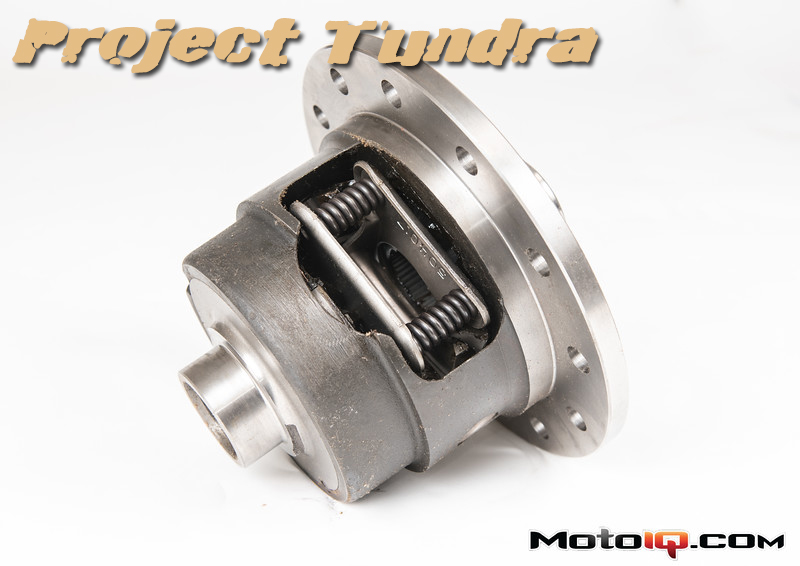

Remove the few hand tight nuts and the differential housing will drop free. This sucker is heavy so be careful. Be sure to drain the gear oil before you even start! Howard bolts the differential carrier to this cool diff assembly jig he made which allows him to lock just about any diff into a vice. That ring gear is huge! It dwarfs the venerable Ford 9″ rear end and is one of the key to the Tundra's really high tow capacity. The Tundra's diff is so much better than the crappy Dana 44 in the Nissan Titan that shits the bed when towing even lightweight car trailers.

That ring gear is huge! It dwarfs the venerable Ford 9″ rear end and is one of the key to the Tundra's really high tow capacity. The Tundra's diff is so much better than the crappy Dana 44 in the Nissan Titan that shits the bed when towing even lightweight car trailers.

1 comment

Where can I get the Auburn gear for the tundra and who does installs near 73858.