,

The first thing Howard does is removes the ring gear and measures the pre loaded turning torque. Usually you use an inch pound torque wrench but Howard is so good, he can tell by spinning it by hand. Howard was surprised on how low the torque was on the Toyota diff.

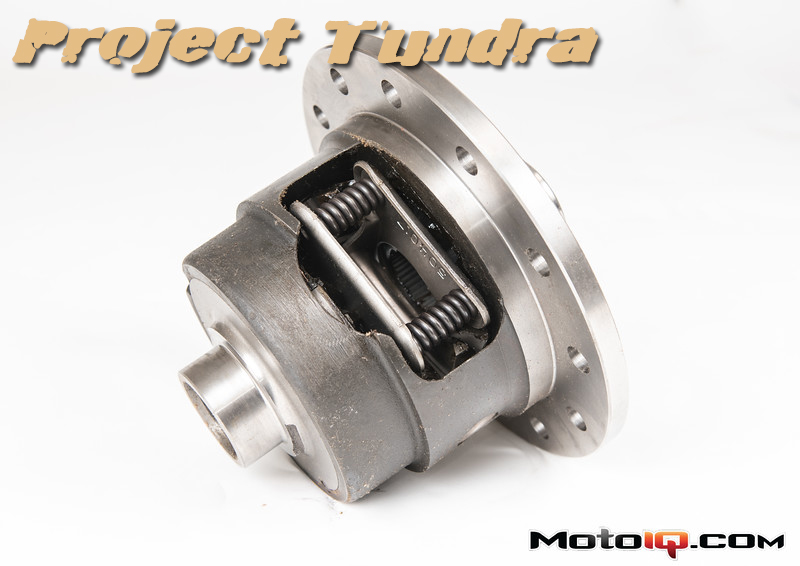

The first thing Howard does is removes the ring gear and measures the pre loaded turning torque. Usually you use an inch pound torque wrench but Howard is so good, he can tell by spinning it by hand. Howard was surprised on how low the torque was on the Toyota diff. Howard then removes the side bearings from the stock diff so he can set the ring gear backlash on the new diff and transfer the bearings to the new diff. Howard has finesses so he hardly ever messes the bearings up. We always seem to mess up the bearings. That's why Howard is awesome.

Howard then removes the side bearings from the stock diff so he can set the ring gear backlash on the new diff and transfer the bearings to the new diff. Howard has finesses so he hardly ever messes the bearings up. We always seem to mess up the bearings. That's why Howard is awesome. The gear backlash is controlled and adjusted by these select fit shims that are placed under the bearing races. By moving the diff and the rings gear back and forth by small amounts using these shims, you control how deeply the ring gear meshes on the pinion and how much backlash or free play the ring and pinion has. Getting this exactly right is critical. Too much or too little backlash can make the diff run noisily or break the ring and pinion easily as the gear loses contact patch.

The gear backlash is controlled and adjusted by these select fit shims that are placed under the bearing races. By moving the diff and the rings gear back and forth by small amounts using these shims, you control how deeply the ring gear meshes on the pinion and how much backlash or free play the ring and pinion has. Getting this exactly right is critical. Too much or too little backlash can make the diff run noisily or break the ring and pinion easily as the gear loses contact patch. Backlash is measured by putting a dial indicator on the ring gear and moving it back and forth feeling the free play and measuring how much there is with the dial indicator. We got lucky as Howard was able to set the backlash perfectly by just swapping the stock shims around. Getting the backlash right almost always involves a trip to the dealer to get different shims.

Backlash is measured by putting a dial indicator on the ring gear and moving it back and forth feeling the free play and measuring how much there is with the dial indicator. We got lucky as Howard was able to set the backlash perfectly by just swapping the stock shims around. Getting the backlash right almost always involves a trip to the dealer to get different shims. Everything is set and the diff is ready to go back in. The ring gear is big so try this pro tip. When sliding the diff in, get it started on the top studs and then line up and push the diff in straight in or the ring gear will hang up and get stuck and you will swear it is too big to fit in the housing. Do it right and it just pops in. No gasket is used so we applied some permatex grey.

Everything is set and the diff is ready to go back in. The ring gear is big so try this pro tip. When sliding the diff in, get it started on the top studs and then line up and push the diff in straight in or the ring gear will hang up and get stuck and you will swear it is too big to fit in the housing. Do it right and it just pops in. No gasket is used so we applied some permatex grey.

1 comment

Where can I get the Auburn gear for the tundra and who does installs near 73858.