,

A 105mm Wilson throttle body does the flow modulation stuff. Of course, it’s billet. I do like the V-band attachments to make sure nothing blows off.

A 105mm Wilson throttle body does the flow modulation stuff. Of course, it’s billet. I do like the V-band attachments to make sure nothing blows off.

The intake manifold is made by Hogan’s Racing Manifolds. It appears the base and runners are machined from billet. Then the plenum is welded on top.

The intake manifold is made by Hogan’s Racing Manifolds. It appears the base and runners are machined from billet. Then the plenum is welded on top. Each runner has a fuel injector along with a fuel pressure sensor. The other line with the T-fittings going into the valve cover sprays oil on the valve springs. The engine does spin up to 10,500rpm so spring oilers are used to improve durability.

Each runner has a fuel injector along with a fuel pressure sensor. The other line with the T-fittings going into the valve cover sprays oil on the valve springs. The engine does spin up to 10,500rpm so spring oilers are used to improve durability. Here are the fluid transfer devices along with MSD providing the spark. The lower red and black cylindrical object with two big lines going into it is the Barnes dry sump pump. The oil drains of the turbos are being scavenged which helps with the tilted-turbo issue. Of course, a Peterson oil tank is used as part of the system.

Here are the fluid transfer devices along with MSD providing the spark. The lower red and black cylindrical object with two big lines going into it is the Barnes dry sump pump. The oil drains of the turbos are being scavenged which helps with the tilted-turbo issue. Of course, a Peterson oil tank is used as part of the system. Nestled between the Peterson oil tank and the Barnes pump is a Waterman Racing Components 21 gallon-per-minute fuel pump. That’s a LOT of fuel flow.

Nestled between the Peterson oil tank and the Barnes pump is a Waterman Racing Components 21 gallon-per-minute fuel pump. That’s a LOT of fuel flow.

The front of the car uses a Lamb Components strut brake system. Yes, that is a carbon carbon brake setup with a 2-piece rotor. A shock pot keeps tabs on the suspension travel over the course of a pass.

The front of the car uses a Lamb Components strut brake system. Yes, that is a carbon carbon brake setup with a 2-piece rotor. A shock pot keeps tabs on the suspension travel over the course of a pass.

2 comments

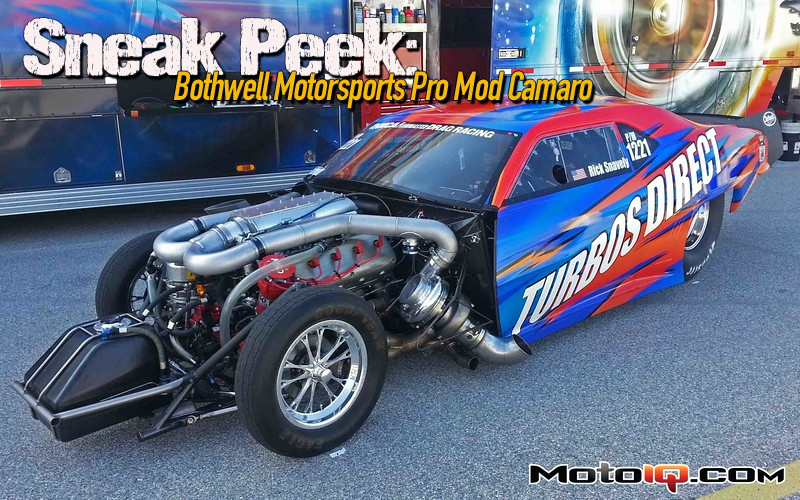

After a single run in the first round at Fontana, Snavely clicked off 5.342 and 5.320 runs (1,000-foot distance) to win the trophy. The team’s goal is to run NHRA next year, so intercoolers were not installed, although they are legal for the NMCA competition.

Thanks for the update!