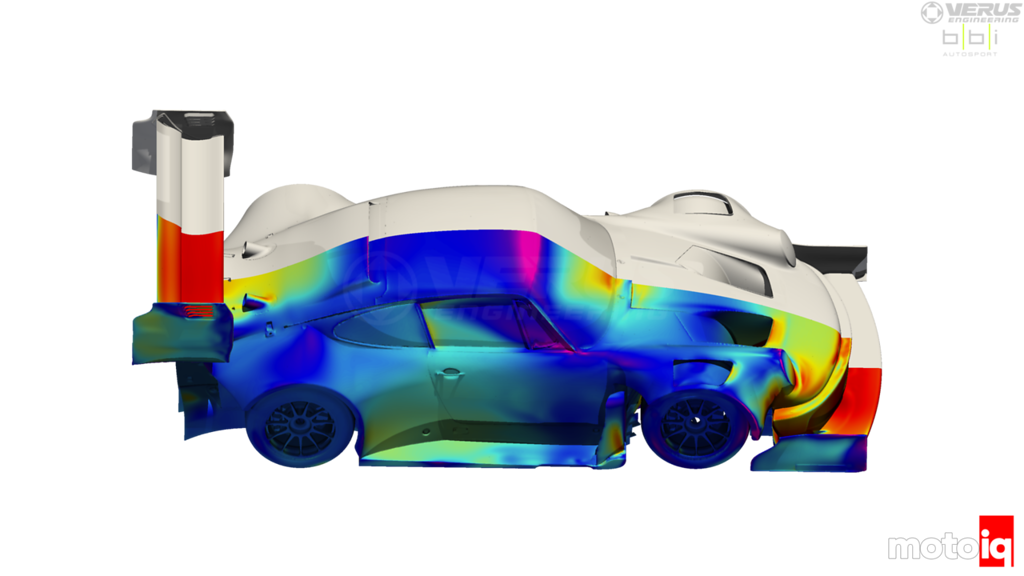

A couple of weeks ago I wrote a story about the aerodynamics of Ken Blocks Hoonipigasus Porsche 911. I was wondering how close I was to being right so I contacted Verus Engineering’s Paul Lucas who designed the car’s aero package to see if he would be willing to do a write-up about how the aero really is on the car. Fortunately, he agreed and wrote this brilliant story on the car’s aero development complete with detailed CFD output.

The CFD Development of Ken Block’s Hoonipigasus Porsche

By Paul Lucas

Front Splitter Aerodynamics:

The front splitter assembly which includes the splitter main plane, splitter winglets, and splitter endplates make up between 35%-45% of the car’s total downforce depending on ride height. The concept behind this splitter has been in development internally at Verus for about a year. We had been working on a design where the splitter had to stay between the outside of the front tires and could adjust aero balance. The concept design had 3 winglets per side for adjustment, and also 3 diffusers on the main plane. The goal of the concept was to make a splitter that would make good downforce efficiently, but also have a linear aero map with ride height and rake.

When BBi came to us with the project for Pikes Peak, we knew the car would have a lot of suspension movement and higher ride height than a normal racecar. The idea to use the concept splitter we had been working on was already in my head. This is because of the class rules for the new car and how the car would be set up for Pikes Peak. Then there was a render of the Scarbo Performance SVRS done by Oilstain that this car was based on. That concept had 3 dive planes per side which had a similarity to the triple winglet design I had been working on. Since we had a concept of what we wanted but never finalized that design, here was our chance to get it working in real life. We went to work on many design iterations of the splitter at many different ride heights and yaw angles. This would ensure that any design we put on the “this works” column, we know worked at multiple ride heights and yaw angles.

The splitter’s main plane is higher in the center than the outer ends where the winglets are located (#1). The whole underside is actually contoured and not just flat with a raised section. It has a large center diffuser where the highest section of the splitter is located. This center diffuser feeds the mid-splitter/t-tray and the rest of the floor. The floor can still be fed air even when the splitter touches the ground because of the main plane design. The two outer diffusers as also fed from the raised section on the splitter main plane. These are large diffusers that exit in the inner wheel wells. The lowest part of the splitter is the outermost section where the triple element winglets are located. The geometry for the winglets and splitter in this location is specifically designed to work even if the splitter touches the ground. Notice how the lowermost winglet is fed air from the top side of the splitter and not just the bottom side.

Three specific parts on the front end cause outwash which can be seen in the image(#1). These parts are the front splitter endplates (#2), bumper turning vane (#3), and upper winglet profile (#4).

9 comments

Thank you for this one! Fantastic article.

Thanks for sharing this Mike, and thank you to Paul/Verus for detailing elements of the aero development.

I hope all involved in the project have a great time at Pikes Peak!

Unfortunately, things didn’t go very well.

This is such an awesome article, written in a way to make something very complex fairly easy to understand for someone with a limited understanding of aerodynamics such as myself.

Are there any rules against moveable aero? Seems like this would be a perfect application of sliding side skirts and possibly even fan driven suction for low speed downforce.

Stuff like that would get destroyed on the mountain.

So sad that this didn’t get to make a run due to the engine failure. Hopefully they do some real shakedowns before next year’s race.

How effective are the NACA ducts at cooling the engine/gearbox? Does it affect the pressure flow under the car thru the diffuser?

Pretty effective, but more testing is still needed. No real change to the diffuser based on before and after CFD runs.