The splitter endplates are very complex flow conditioners. The endplate helps keep the low pressure under the splitter even at high ride height with the vortex generator at the leading edge (#1).

Usually, this type of vortex is created with geometry on the outside of the endplate, but that wasn’t possible. The endplate couldn’t be that wide or we would have to narrow the splitter. The leading-edge vortex generator solved this problem in a unique way. The cross-sectional shape is profiled and changes throughout its height to control the flow and help create outwash (#2). Everything about the design of the endplate is designed to control flow on the front end of the car.

The splitter winglets are 3 different custom airfoil profiles. The lower 2 are a 2d profile that is the same left and right. The upper most is a 3d profile with differing chord lengths and differing angles from the innermost section to the outermost. This is to help outwash and airflow around the front tires. Each winglet is independently adjustable from the other (#1). The lower 2 winglets adjust 8 degrees each and the top adjusts 9 degrees total.

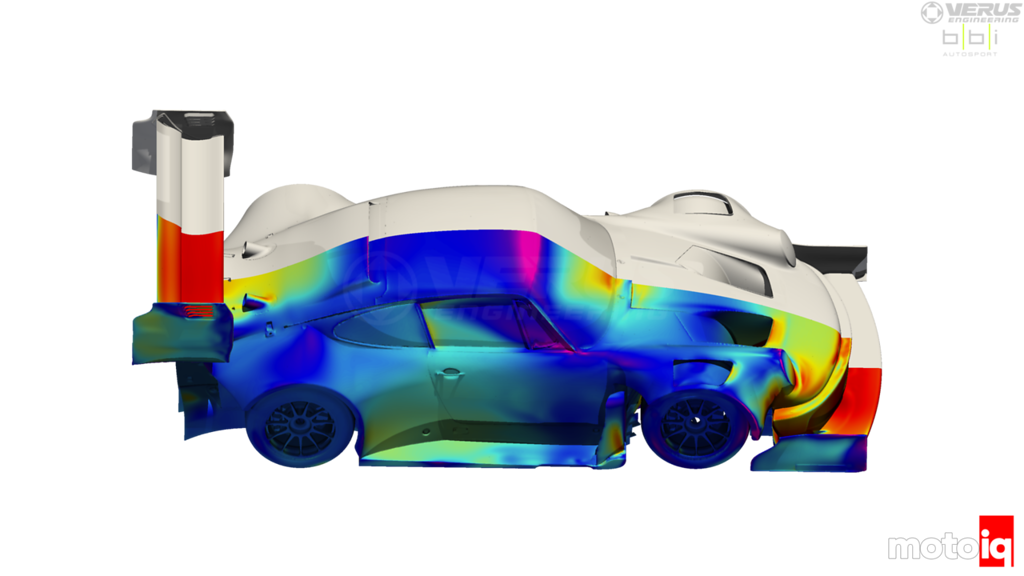

Floor Aerodynamics:

The floor is physically one of the largest parts of the car producing 35-40% of the total downforce. The floor in general was kept pretty mild as we were dealing with a large ride height window. The very front of the floor has a mid-splitter/t-tray (#1). This type of design is seen in many different professional race cars. The mid-splitter takes air on the top side and funnels it outboard and into the vortex generators on the outer leading edge. This energizes the flow to the floor and tunnels. The bottom of the mid-splitter feeds air to the three NACA ducts and center diffuser.

The 3 NACA ducts (#2) work to send fresh air to the engine, gearbox, and turbo manifolds. The center NACA duct is the largest and that is to feed air to the engine and gearbox. The smaller outer two are used to feed air between the floor and the turbo manifolds to keep that area from getting too hot. Keeping the car cool was a huge priority and very important on a racecar.

The outer tunnels (#3) start very early and are long. Their job is to help move a large amount of air under the car and recover pressure behind the car. The rate of expansion for the tunnels is kept relatively mild because of the major ride height changes. They are still the most sensitive to ride height on the floor, but their sensitivity was kept to a minimum by controlling the volume expansion. The rear suspension wishbones ride inside the tunnel but cause very few issues. That is because tunnels operate on volume expansion more than attached flow to the surface. The tunnels have removable strakes that can be replaced. This is because it is the lowest part in the rear of the car and will wear away.

The rear diffuser (#4) has an early large expansion and a slow expansion towards the rear. This helps make downforce at higher ride heights and limit sensitivity as ride height decreases. The strakes help control the flow in the diffuser section from the rear tire squirt. Inside the diffuser, there is a keel shape for drivetrain space and to help with diffusion in the center.

9 comments

Thank you for this one! Fantastic article.

Thanks for sharing this Mike, and thank you to Paul/Verus for detailing elements of the aero development.

I hope all involved in the project have a great time at Pikes Peak!

Unfortunately, things didn’t go very well.

This is such an awesome article, written in a way to make something very complex fairly easy to understand for someone with a limited understanding of aerodynamics such as myself.

Are there any rules against moveable aero? Seems like this would be a perfect application of sliding side skirts and possibly even fan driven suction for low speed downforce.

Stuff like that would get destroyed on the mountain.

So sad that this didn’t get to make a run due to the engine failure. Hopefully they do some real shakedowns before next year’s race.

How effective are the NACA ducts at cooling the engine/gearbox? Does it affect the pressure flow under the car thru the diffuser?

Pretty effective, but more testing is still needed. No real change to the diffuser based on before and after CFD runs.