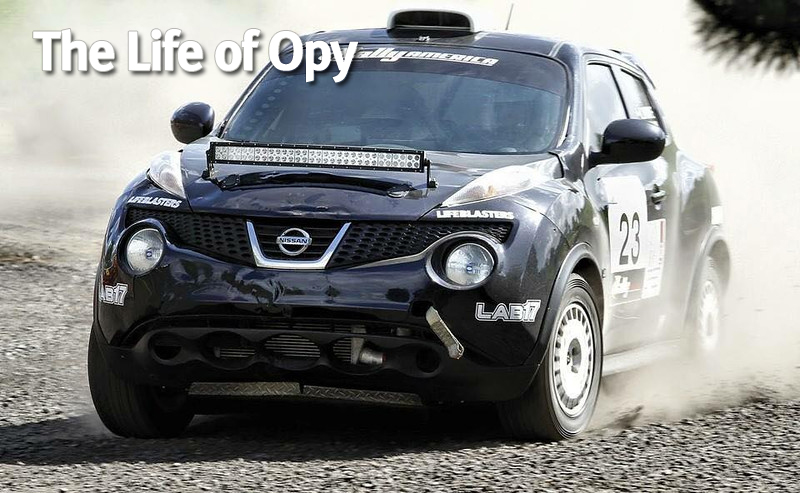

The Life of Opy: Part 2 – Building a Better Opy

There aren’t a lot of off the shelf parts available for a Nissan Juke. In part 2 of this series Lars Wolfe fabricates or adapts many parts and updates the shifting pattern to get Opy further race ready.

The Juke could only be had in AWD paired with the CVT transmission. The silver lining is rally-car like sequential shifting. Racers like to downshift forward, upshift back for their sequential shift setup. Why? Because you typically downshift while braking, so the G-forces naturally make it easier to push forward and vice-versa for accelerating and upshifting. It seems only Mazda gets this within the more pedestrian car brands (and I’m sure our Dave Coleman has a part in this). Fortunately, the transmission shift lever is just an electrical switch. Electrical switches can be rewired.

The Juke could only be had in AWD paired with the CVT transmission. The silver lining is rally-car like sequential shifting. Racers like to downshift forward, upshift back for their sequential shift setup. Why? Because you typically downshift while braking, so the G-forces naturally make it easier to push forward and vice-versa for accelerating and upshifting. It seems only Mazda gets this within the more pedestrian car brands (and I’m sure our Dave Coleman has a part in this). Fortunately, the transmission shift lever is just an electrical switch. Electrical switches can be rewired.

Dig into the connector, figure out which wires do what, do a little swap-a-roo, and voila! The transmission now has a proper shift pattern for a race car.

Dig into the connector, figure out which wires do what, do a little swap-a-roo, and voila! The transmission now has a proper shift pattern for a race car. Remember Opy had a bit of damage which is why Lars was able to obtain Opy for a good price and provide a good home. Part of the damage was to the front core support, so Lars fabricated a new one.

Remember Opy had a bit of damage which is why Lars was able to obtain Opy for a good price and provide a good home. Part of the damage was to the front core support, so Lars fabricated a new one. Why buy OEM when it can be fabricated stronger and cheaper?

Why buy OEM when it can be fabricated stronger and cheaper? To bring the charge air temps out of the turbo down, a used Evo intercooler was fitted to Opy which is significantly larger than the stock Juke intercooler. To make space for the larger intercooler, a smaller radiator was fitted. A lightweight front bumper bar was also fabricated at this time to shave some weight.

To bring the charge air temps out of the turbo down, a used Evo intercooler was fitted to Opy which is significantly larger than the stock Juke intercooler. To make space for the larger intercooler, a smaller radiator was fitted. A lightweight front bumper bar was also fabricated at this time to shave some weight.