,

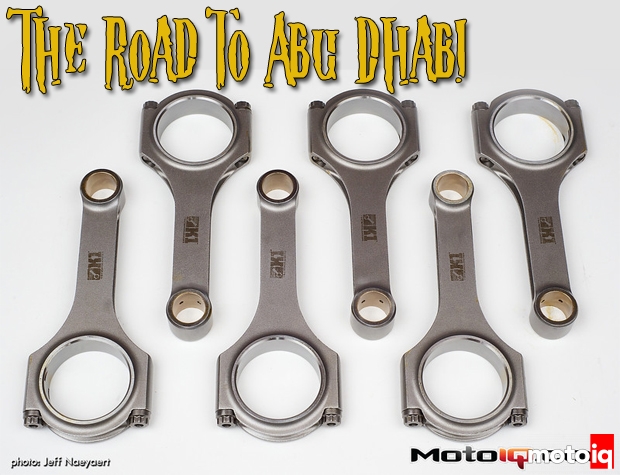

The next most important item for a high powered engine is the connecting rods. Again we had to choose something that we could get immediately which meant shelf parts. Unfortunately our rod of choice from Cosworth had just gotten discontinued due to poor sales, so we chose K1 Technologies. K1 Technologies is a high quality rod. The K1 rod is an H beam profile designed, finished and machined in the USA.

|

| With heat treated 4340 forged billets, super close tolerance for dimensions and weight and shotpeening for good fatigue strength, K1 Technologies rods are an awesome value. |

The rod itself is machined from a forged 4340 steel billet. 4340 is a heat treatable alloy steel similar to chrome molly, having nickel, chromium and molybdenum as alloying agents to give it roughly double the strength of regular steel with a higher nickel content making it stronger and tougher with a higher impact resistance. These properties make 4340 an ideal alloy for connecting rods. The rod is first machined then solution heat treated. This heat treating greatly improves the mechanical properties such as tensile strength of 4340 steel. Solution heat treating makes the alloy homogeneous where all of the atoms in the material effectively become a solid solution during the treatment making the alloying elements evenly distributed around the part.

The rods small end is bronze bushed and the rod machined so the sizing can be held to plus or minus 0.0001 and the weight within one gram per end. Those are exceedingly tight tolerances! After treatment the rod is shotpeened which can improve fatigue strength by over 100%. Another cool feature is the use of high strength 200,000 psi ARP 2000 rod bolts. These premium bolts have asymmetrical threads for more thrust engagement for better torque consistency.

|

| The highly stressed rod bolts are usually the weakest part of any rod and the K1 rods do not skimp here one bit. K1 chose 3/8″ ARP 2000 high strength bolts, at 200,000 psi, they are among the best you can get. |

The K1 rods use a beefy 3/8 inch bolt and weigh only 528 grams, almost 100 grams lighter than stock. Less reciprocating weight on our pistons and rods mean less stress on the crank and bearings. These rods should easily take our needed 8000 rpm and our anticipated power levels without breaking a sweat. A call was made to K1 and a set of rods was shipped out to us from Michigan via next day air.