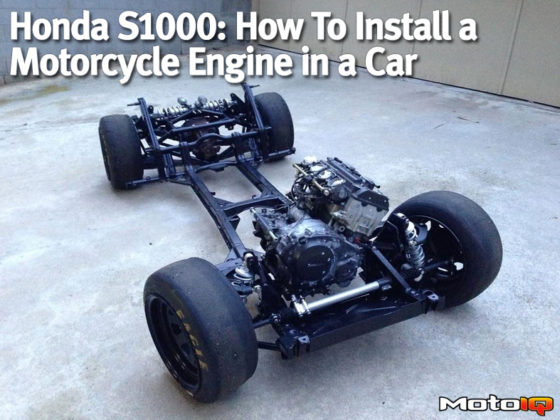

We have known Michele Abbate ever since she was a college student doing track days with her trusty Mazdaspeed Protege and have followed her career as friends as she has progressed up the ranks from recreational driver to a Scion Sponsored driver in SCCA’s STU class.

In GT1, Michele has to run against some heavy competition, mainly V8 powered domestic machines in her Edelbrock Supercharged Toyota 86. Although she has been doing pretty well in the class, if she has any hope in doing okay at the annual Runoffs, her engine is going to need a big injection of power.

Here is where we are coming in. Up to now, Michele has been running her car with a bone stock FA20 engine at a very low boost street blower drive ratio. Although this is decent power, she needs a lot more to be competitive in one of SCCA’s fastest classes for production-based cars.

Our goal is to build her an engine strong enough to take more supercharged boost while keeping great reliability. We will also be increasing the engine’s VE to make more power at higher RPM as well. It’s a tall order, but we are gonna try to pull this off without losing any bottom end power- just making the engine’s powerband broader. How are we going to do it; check it out below!

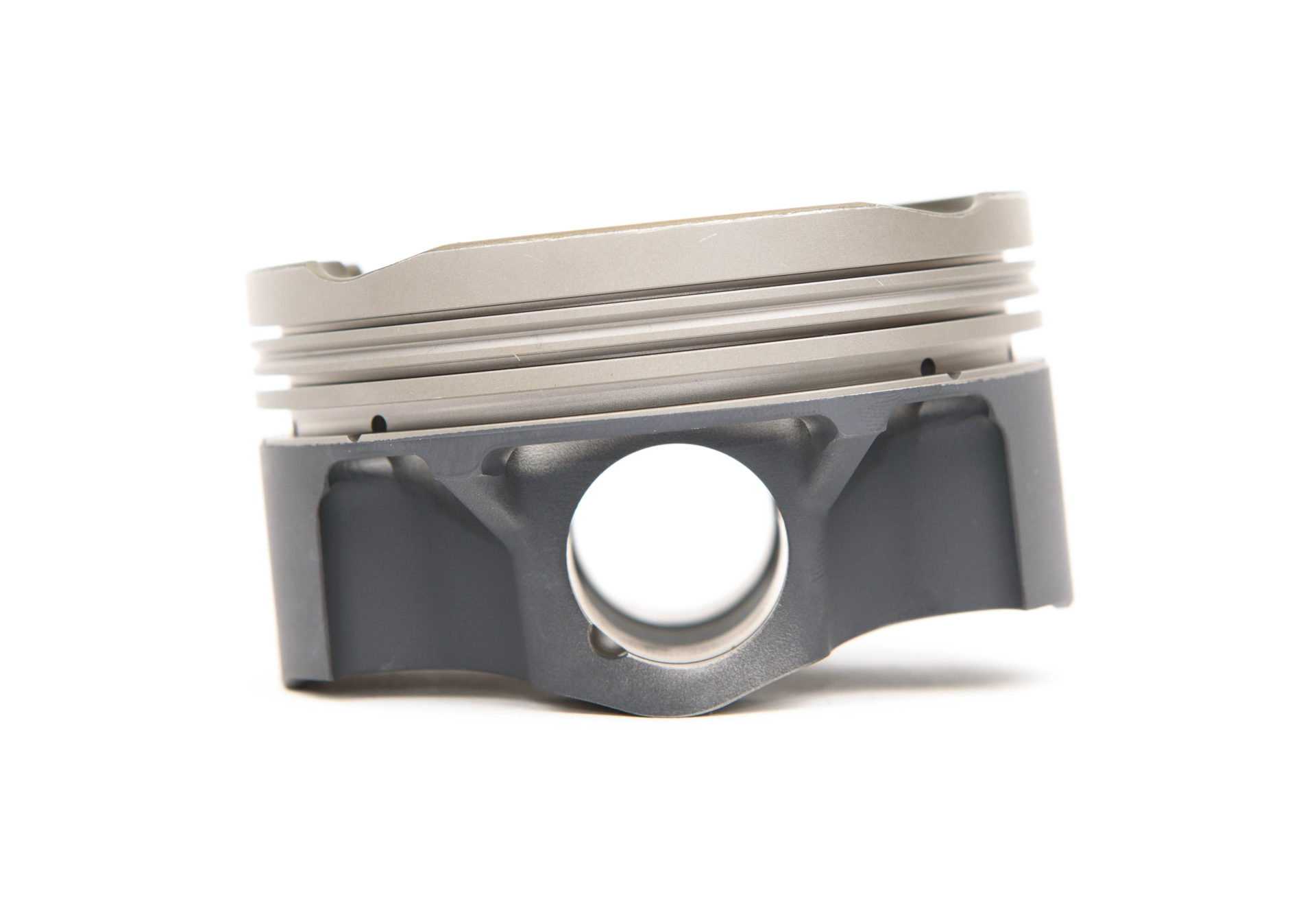

Since Michele’s FA is going to be subject to forced induction stress for long periods of time in road racing use, we decided to source what we feel is one of the best connecting rods- period. We obtained a set of Pro-H beams from Carrillo. The benefit of an H-Beam is higher resistance to lateral torsional buckling, which is the primary mode of failure for most I-beam structures under compression.

The H-Beam is for extreme use and is stronger for its weight because its resistance to buckling loads is greatest in the direction in which the rod is stressed the most. The H Beam is a more expensive design because the forging is now a multi-step process.

Carrillo rods are heat treated using a maraging process, resulting in an ultimate tensile strength of 195,000 psi with a yield point of 182,000 psi. Maraging means that the alloy used is a maraging steel alloy. These alloys are known for strength without the brittleness associated with many strong and hard steel alloys. A Maraging alloy is precipitation heat treated to convert most of the austenite (a less strong form of steel) to martensite (a stronger form that the heat treating distributes through the steel’s crystal structure).

All Carrillo connecting rods are CNC-machined from an oversized blank forging resulting in the proper grainflow and are surface machined to ensure the removal of any potential inclusions or surface conversions such as scale generated by the forging process. These inclusions can cause stress risers that reduce cyclic fatigue strength.

A final multi-stage shotpeen operation completes the rod. Shotpeening greatly improves fatigue strength by forming a tough fine-grained surface skin on the part. Carrillo Rods are fully machined, Magnaflux inspected and balanced as a set to +/- 1 gram before being shipped to the customer.

The small end of the rod has oil reservoir countersink on the top of the rod’s small end. This helps the small end of the rod get better lubrication. The rod’s small end bushing is aluminum silicone bronze with a very smooth surface finish of 4RA in addition to lapped sides and a radius on the outer shoulder to be easier on the wrist pin.

With any rod, the bolts are the most highly stressed and critical part. Carrillo Pro-H rods come with CARR fasteners. The CARR fasteners are made from multi-phase TM material, giving them a higher Ultimate Tensile Strength (UTS).

Carrillo rod bolts are a proprietary design with asymmetrical threads that have more engagement on the thrust side for better strength and more accurate torque readings. The base bolts are made of super strong H11 tool steel. H11 is a steel alloy with high amounts of chromium that exhibits a high degree of tensile strength and toughness. The H11 bolts have an impressive ultimate tensile strength of 220,000 PSI.