,

|

| We WPC treated the Cosworth steel thrust bearings for lubricity. |

|

| Cosworth blueprinted our crankshaft by deburring it, balancing it and polishing the journals. |

|

| The crank oil hole were chamfered. We also WPC treated the crank to improve the journal surface friction and to improve the crank's fatigue strength. The stock VQ crank is a very robust piece. |

|

| We are also going to use Cosworth's blueprinted VQ35 oil pump. Cosworth starts with a rev up pump because it has thicker gears for greater volume capacity. They then deburr the gears and WPC treat them. |

|

| The oil passages are bored larger and radiused and the pressure relief valve bore is honed. Finally the housing itself is WPC treated. The Cosworth pump flows 15% more volume than a stock pump. If you wonder why Cosworth uses WPC so much it's because it flat out works. The guys at Cosworth turned us on to WPC several year ago. |

|

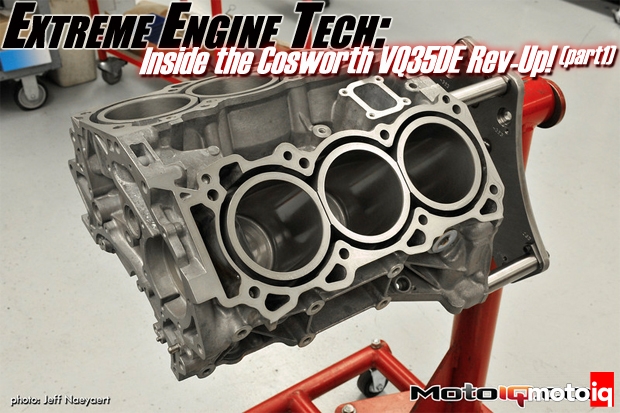

| Our VQ35DE Rev-Up block was ultrasonically cleaned, deburred, align honed and bored, and honed with bespoke fixturing including torque plates on the deck surface. This causes the block to distort like an assembled block with the stress of the fasteners holding it together. This means that the bores will be perfectly round when the engine is together. This ensures good ring seal, quiet operation and long life. |