,

|

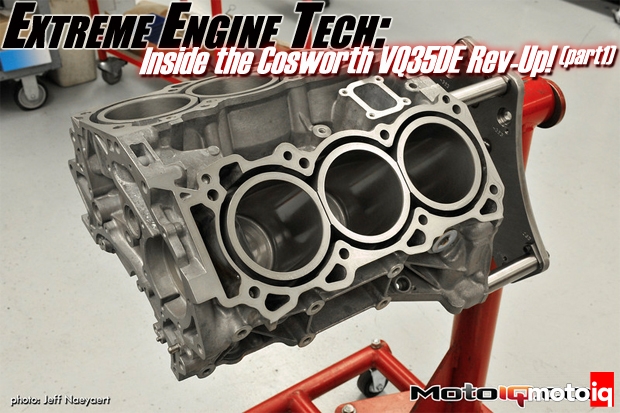

The Cosworth Multi layer steel gasket is a high quality part. The gasket is made of 3 individual layers of stainless steel die cut to tolerances of 0.002″. Die cutting is better than the more common laser cut because it makes for a more uniform thickness and smooth edges. Each individual stainless layer is coated with a thin layer of nitrile rubber for better sealing. Perhaps the most important advantage that the Cosworth gasket has over typical MLS gaskets is a folded center stopper layer. This means that the center layer is folded back onto itself which provides a much greater clamp load around each cylinder. This is many times better than your typical MLS gasket which has a little embossed ridge around the cylinders. |

|

| Cosworth's phenolic heat isolating intake manifold gaskets help keep engine heat out of the manifold to help keep charge air temps lower. |

|

| Our valvetrain uses JWT C9R cams and Supertech 1mm oversize valves. The JWT C9R is one of the most aggressive VQ profiles available with a whopping 0.516″ of lift and 283.5 degrees of duration. We have had extremely good luck with these cams on Dai Yoshihara's 350Z. |

|

| Our Supertech valves are beautiful works of art! |

|

| Our Supertech valves are 1mm oversize on both the intake and exhaust side of the engine. The intake valve is made of martenisitc stainless steel for hardness and strength then nitrided for long wear. The exhaust valve is made of Inconel, and exotic super heat resistant aerospace alloy with a high nickel and copper content. |

|

| JWT valve springs are frequency matched to the cam profile to avoid surge and are made from the highest quality vacuum degassed, electrically purified Kobe spring steel. Even though the cams have an aggressive profile, frequency matching enables a spring with surprisingly low tension to control the valve motion. This reduces friction and wear. |