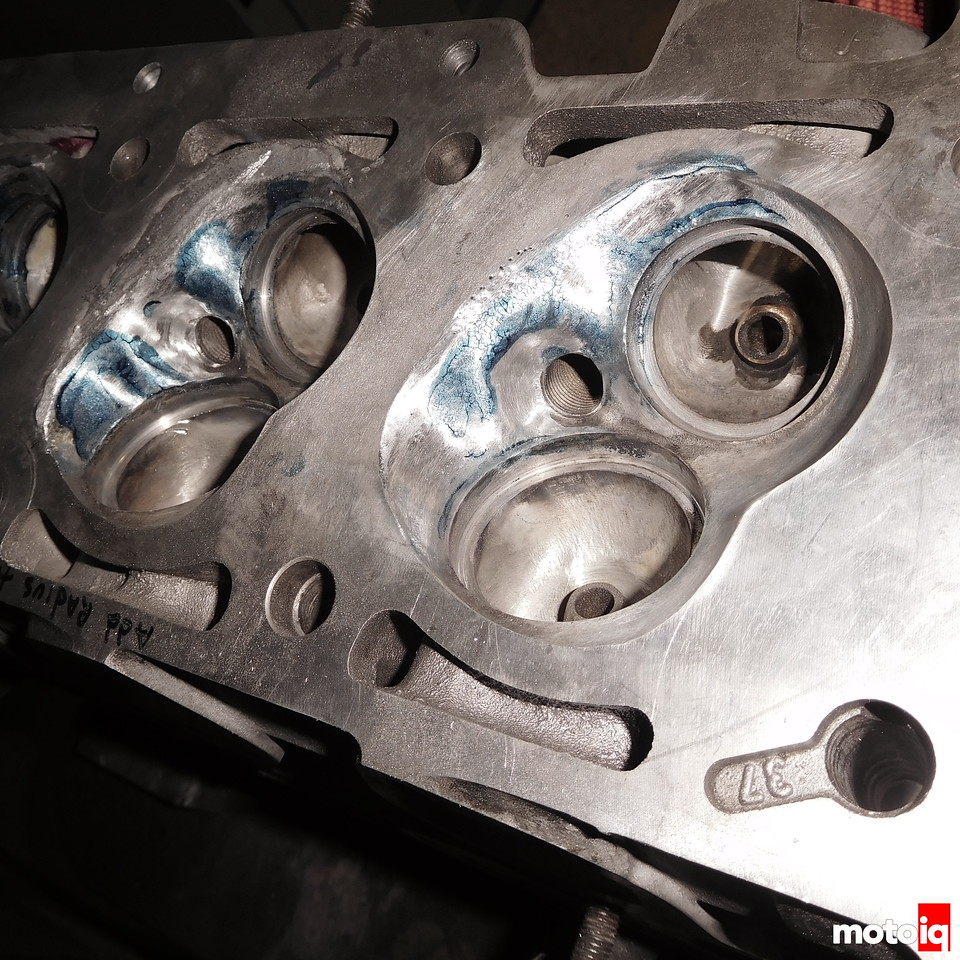

I recontoured the combustion chamber to improve the intake air flow and get the four different runners to equal each other in CFM. For the exhaust I installed a “shark fin” on the floor of the exhaust port runner. You can see the improved results.

If you want to learn more about Internal Combustion Engine air flow, there are many paths to Air Flow study and learning. My personal path of study includes some Fifty plus years of watching, listening and reading anything and everything I could get my hands on – automotive, motorcycle and aerospace. I have purchased and read countless books, SAE Papers, Journals, magazines, and spent countless hours in college libraries – anything and everything that I felt might increase my base of knowledge. Internal Combustion Engine Airflow is a massive subject that includes amongst other studies, Fluid Dynamics, Thermal Dynamics, Physics, Chaos Theory, Mechanical Engineering, etc., etc., etc. Thinking that you can master this subject quickly, like in a few weeks, which I actually had someone say to my face, is plainly ignorant and self-delusional.

As Frank Zappa (an others) have said. “Ignorance is the most abundant element in the Universe…”

34 comments

GREAT ARTICLE!!! invaluable insight!! thank you!!

Thank you Wes.

The quench in the combustion chamber will be improved as well as the flow quality lending to better mixture distribution in the cylinder. The BSFC should go down and the engine will probably like less timing. This is somewhat reminiscent of the Soft Head porting and combustion chamber modifications that Larry Widmer did in the 80’s.

Thank you Mike.

Yep, or people like Harry Weslake way before that…. Hemi combustion chambers tend to create low compression on smaller displacement engines. Story of my life, as I tend to mess with them in my spare time. You could actually diffuse mixture from outside the quench area if you make small channels running towards the spark plug. if the quench angle is actually quite steep on a 2 valve with the spark plug on the side. Rounding of the quench also helps a bit. But you should only do that if your can maintain a high enough compression ratio. Otherwise compression should always be leading.

Then again: port angle an radius are a lot more important, but also the stuff where it becomes really tricky. Not so much for grinding, but actually changing the angle and port itself without casting a new head.

Funny you should mention that. I used the same technique in building up my Honda Ruckus Scooter. Had the chamber welded up to make a lot of quench and to bring up the compression ratio to over 13:1. Then I added the channels to the plug because I read some white paper about it. This thing ran really hard for a 50cc scooter, it could go 60 mph with my fat ass on it and I could outrun guys with a 125cc GY6 engine swap. Many other people have tried to follow my lead and build a fast 50cc but no one has come close!

Way to go Don!! You are the Professor of porting.

Thanks love, I’ll cook dinner tonight for that.

Don

Great to see you “un-leashed” in your forte!

Good onya Don, RF.

Thank you Fred, Mister Indian!

That takes an impressive amount of knowledge and determination to modify a cylinder head with such a poor overall performance, and see the significant improvement that was displayed here. Sounds like many hours of work and quite a bit of patience were required, as well. Very interesting article, well written and thoroughly descriptive in content.

Such a cool article, the old school art of hot rodding.

Thank you for sharing!

Thank you Miguel for your nice comment. Old is the optimum word in my particular case.

Stay tuned, there is more coming.

Don

Dear Don,

Many thanks for the article about the 2002 cylinder head modifications. It demonstrated an unusual and innovative approach to gas flow. I was particularly impressed by the test facilities that you have on hand to prove your ideas before putting them to trial as is the traditional suck-it-and- see method. It must save a lot of scrap! Also what is impressive is the outside specialist support that you are able to call upon and your patience and dedication to the project. Sadly for me, you are now going way beyond my own capabilities these days.

Best regards

Bill

Thank you Bill. Nice to know that MotoIQ is making it all the way to England

A well written (and entertaining!) article. Folks with this kind of dedication and who make fast engines. It’s all about brains and sweat.

Thank you Kris

Jackson

Congratulations Don you are The Man.

Great article Don! Wish I had known about Replika Machinen when I was driving my 76 2002. To date one of my favorite cars. As a current customer I appreciate your dedication to the art of air flow and the paramount pursuit of perfection!

Thank you Jeromey

Great article. I am actually about to start on a rebuild project with my 2002 (with x60,000 miles). I won’t be able to to this level work certainly! Any recommendations for shops to do more basic head work in the Bay Area?

Thank you for your comment. We can and do, do less involved cylinder head work. Mike asked me to feature this project as it shows what can be accomplished by people with lots of experience in cylinder head and engine work.

Call me and we can discus your project.

Don

Great article Don! You are a wealth of information. On a side note, Don has been working with us on a new cylinder sleeve design. Stay tuned for more on that.

Thanks Jeff, I guess I better call you!

Good job. It is a good article for those that want to learn.

It is unfortunate that most of the readership do not understand how much work it

is to do the work on the parts and test them AND then generate the words to

explain it to them. I hope they pay you for these efforts.

Regards,

HB2

Thank you Harold for your comments and encouragement.

Don

Don, many people believe that a cylinder head is just a lid with holes for the valves; you’ve proved that it is much, much more.

It was a lot of hard work, but what a good job well done.

Eddie.

Coming from a world class restoration expert like you that is high praise.

Hope you are doing well over there.

Thank you, Don

Thank you Billy.

Three positive comments from over “The Pond”. Spanning the Wide World of Air Flow.

Don

I’m really interested in seeing what kind of numbers the little m10 will put down with that kind of flow improvement..

Thank you PJ.

I am only involved with the cylinder head. At this point what, when and where as far as the rest of the engine goes are a mystery.

Don,

what ‘s and arm wavy cost to do this work AND now that you’ve done all this learning would a 2nd head like this one be cheaper?

I think that you are asking about the price to reproduce this cylinder head. Cheaper???

I have been porting 2 and 4 stroke cylinder heads for over 40 years. What is that life experience and knowledge worth?

It has taken a LOT of work to get to the combustion chamber and the CFM to the point that it is currently.

Will additional “copies” of this cylinder head be less expensive than the original? Possibly, that depends upon the demand.

If you are truly interested then you can call me and we can discuss it.

Don Redmon

Replika Maschinen, Inc

831-359-0863