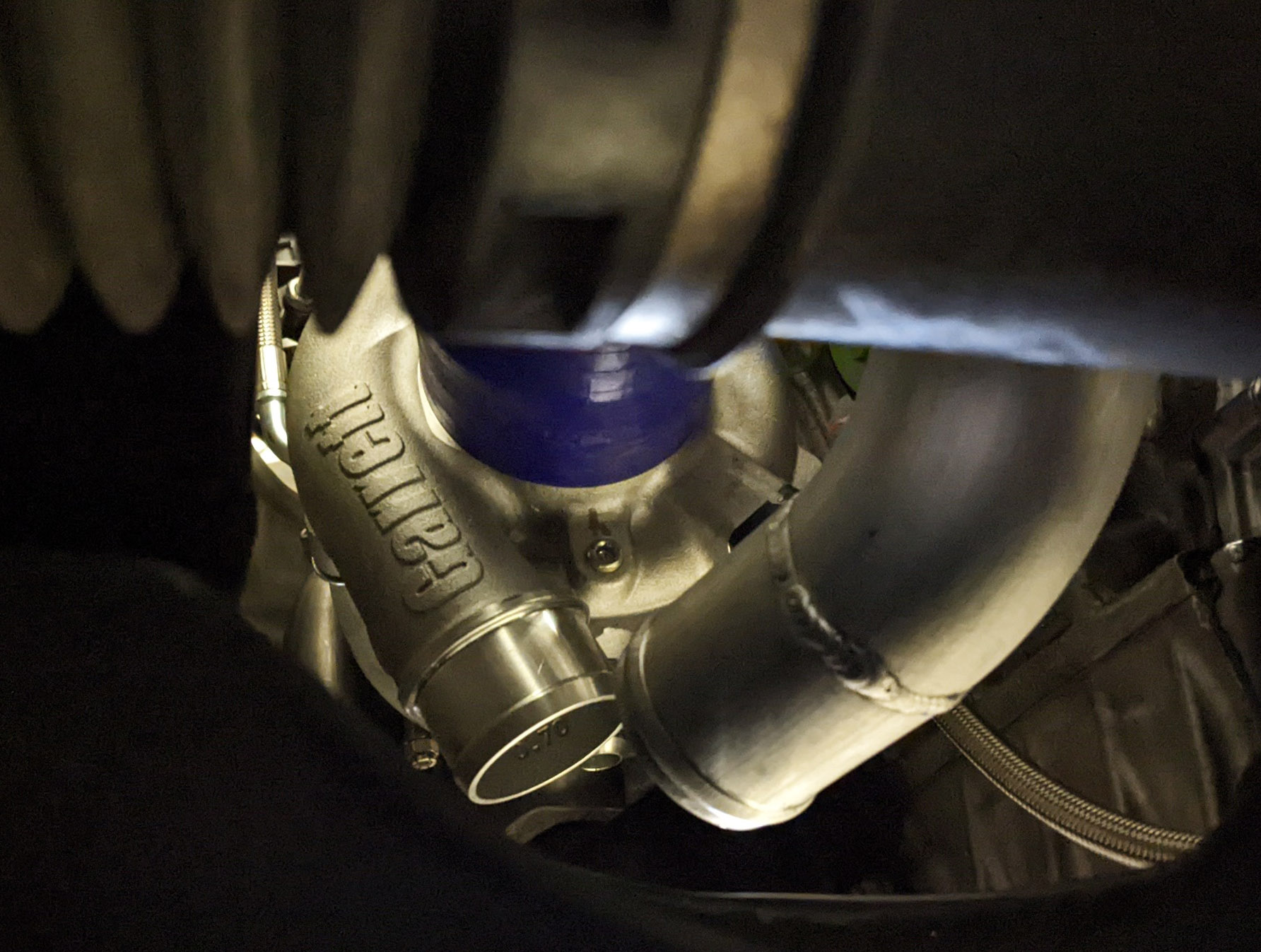

A long radius 90-degree fitting attaches to the drain of the turbo and still leaves space for the compressor outlet to intercooler piping.

Here is the mock-up of the future oil drain line. Brendan took this back to the shop and had the real thing made and pressure tested. If you were a car shop, you’d send in the specs of the mock-up and Dyme PSI could have you the real thing the next day if in the US. Or within 3 days globally. And the parts are fully pressure tested to ensure leak-free performance.

Onto the coolant hose routing for the air to water intercooler system. I started with the intercooler outlet going towards the front of the car. Eimer Engineering cut/bent/welded brackets to the intercooler to secure it to the main cross member going across the engine bay. Word of advice, avoid worm gear clamps and stick to constant tension clamps. Worm gear clamps can loosen over time with thermal cycling. When you pop the hood on any car, there’s a reason why you see constant tension clamps on coolant hoses.

There’s a gap between the radiator and frame through which to route the hose. I had foam blocking this path to force more air through the radiator. I just had to move the foam a bit to make space for the coolant hose. I’ll need to do something to protect the hose against the bit of sheet metal rubbing on the hose.

The flow path then feeds the heat exchanger.

7 comments

That AN line kit is pretty cool, I haven’t seen that before.

Do you still have that alternate vented hood? Seems like it would come in handy to dissipate the heat from the turbo considering how high that air intake is in the engine bay.

Glad to finally see another post on this car. Always loved the chassis, it just needs some power to make it golden.

I gave that hood to the owner of Project AP1 S2000. I’m staying completely stock hood sticking to the sleeper stealth theme. A NACA duct right in the middle of the hood where the intake is would be optimal, but that would attract unwanted attention. While sitting stationary, the intake will suck up some of the warm air coming off the manifold/turbo. But I figure in first gear, the car will be traction limited anyway. Once the car is moving, I’m plumbing cool air towards the intake, so it should be sucking in near ambient temp air. We could possibly fab up an airbox to completely isolate the intake from radiator air, but I don’t think it’d be worth the effort.

That engine bay is looking mighty crowded, I don’t know if you could get some kind of snorkel to vent into the air filter like this:

https://www.s2ki.com/forums/s2000-modifications-parts-193/custom-piece-fipk-snorkel-pics-728433/

Yeah, I understand wanting a sleeper. I had my first car stolen within six months because I put some chromed aluminum 17” wheels on it. When I got it back (with some crap steel wheels) I used the insurance money to search for the lightest, yet stock looking aluminum wheels I could find. I eventually turned it into an auto-X car, but I was always mindful to remove the race wheels and slicks immediately before going home.

Because of that initial experience, I have always tried to make my street cars look understated. I absolutely subscribe to the ‘sleeper ethos’….because, as you say ‘life.’

I have to admit… I was eyeballing a Dodge Viper hood NACA duct… I talked myself out of it to stay under the radar. Some of the air from the driver side bumper duct will work its way into the engine bay. The passenger side bumper duct will be the primary way to plumb ambient air to the intake. When the front bumper is fully mounted, there may be a gap between the top of the heat exchanger and the top of the bumper opening. If so, we can make another air diverter plate to force air to go over the top of the radiator like the snorkels.

Great build! Is the turbo manifold available for sale? Ready to purchase

I’m waiting to get my car tuned to determine the wastegate performance before I sell the one spare manifold. I’ve been driving it around, making sure all the small things are in proper working order before going in for a tune. I’m hoping to have it all ready by the end of September.