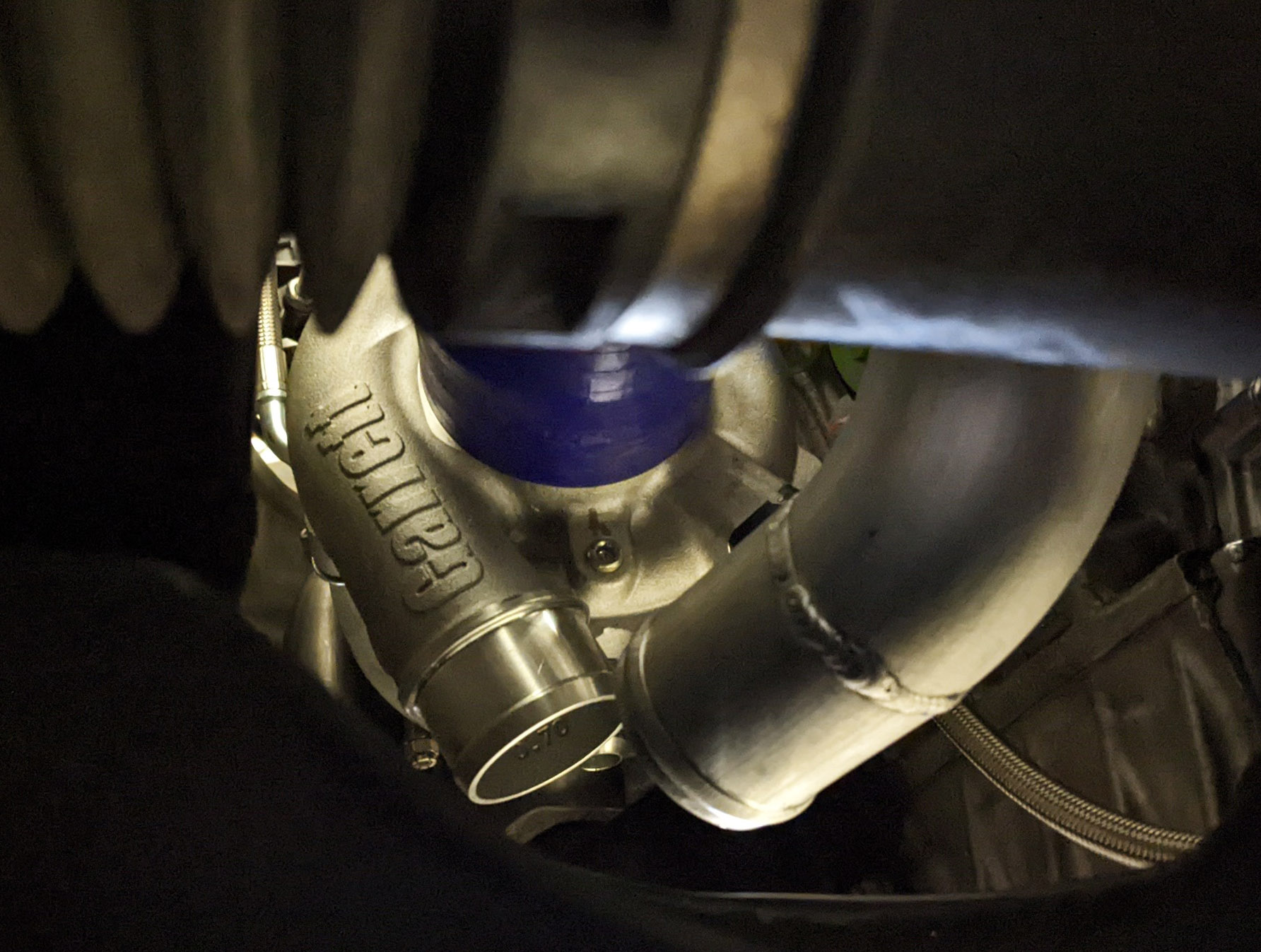

The compact Garrett G25-660 uses a 3” diameter intake and 2” diameter compressor outlet. The next frame size up typically uses a 4” intake and 2.5” outlet. You can see how tight it is to fit the 3” diameter intake and the 2” diameter intercooler pipe. Thank goodness we, I mean Eimer Engineering, didn’t have to route bigger size pipes! Note they had to cut off the 2” hose barb I had on the intercooler in order to weld on a 90-degree bend due to the lack of space. The Garrett G-series packs a lot of power in a compact package making it the ideal turbo for this setup. Oh yeah, notice the nice design detail Eimer Engineering did with the dimple die hole in the intake pipe bracket to cut weight and add rigidity. They also fabricated the sheet metal air deflector you can just see under the intercooler.

The goal of the air deflector is to direct the hot air coming out of the radiator downwards and under the car to avoid having that hot air sucked up into the intake. Sucking hot air into the turbo makes it laggier and increases exhaust back pressure because the turbo has to spin faster to push the same mass flow of air. We tried using this space between the radiator and engine bay cross member to locate the remote oil filter mount, stock oil cooler donut thing, oil sensor sandwich plate, and oil filter. But in trying to route the oil lines with Brendan of Dyme PSI, we didn’t like the options for how we’d have to hang the assembly. The stack of parts is quite heavy and I didn’t like the thought of all that mass hanging off of a bracket. It would have been a pain to change the oil filter too.

After trying to put this big stack in a few locations, I settled on this spot next to the intake tube, shock tower, and intercooler. The stack has to be elevated a bit (I put some scrap coolant hoses pieces underneath the stack to hold everything up) for the oil lines to clear the A/C line. The air deflector will need to be trimmed to make space for the oil lines to go from the remote mount back to the engine. I will also need to route coolant lines for the oil cooler along the same general path of the oil lines.

The oil pressure and temperature sensors nestle into this gap which works out well and the mating wire harness connectors are right there. Did I mention this is a tight fit? It seems to be a common theme.

Changing the oil filter will be a snap now like on the FT86/GT86/BRZ/whatever it’s called. We’re going to stuff foam between the air deflector and radiator to take up that gap like we stuff foam all around the A/C condenser and radiator. It’s a trick I learned from the former head of engineering at Stoptech way back in the day. Note I have the stock black header heat shield loosely put in place. Yup, the turbo manifold fits under it. The air-to-water intercooler setup adds a ton of complexity, but the result is having only about 2 feet of intercooler piping which will improve response.

I put the bumper loosely back on to see how everything looked. I think the heat exchanger for the intercooler system sticks to the stealth theme.

I did find a clash issue. The Baero front bumper duct runs into the water pump. We’ll have to cut back the duct to clear. The idea for the ducts is to feed cool air to the intake. We can’t run an actual duct anymore on the driver side, but air finds the path of least resistance. So cool air should still make its way up into the engine bay by way of the hole by the coolant bottle. We’ll have to see how everything lines up with the bumper properly mounted and maybe come up with an air diverter strategy to get even more cool air to the intake.

There’s still a good list of things to do. We’ll need to enlist the help of Dyme PSI again to create the last oil lines now that we found a home for the remote oil mount. And there are the coolant lines for the stock oil cooler and turbo, fuel pump and wiring, fuel injectors, wideband wiring, fan and water pump wiring, air oil separator plumbing, spark plugs, and probably a few other things I’m forgetting. We’re a heck of a lot closer now to running with the help from Eimer Engineering and Dyme PSI.

Sources

Eimer Engineering

Dyme PSI

7 comments

That AN line kit is pretty cool, I haven’t seen that before.

Do you still have that alternate vented hood? Seems like it would come in handy to dissipate the heat from the turbo considering how high that air intake is in the engine bay.

Glad to finally see another post on this car. Always loved the chassis, it just needs some power to make it golden.

I gave that hood to the owner of Project AP1 S2000. I’m staying completely stock hood sticking to the sleeper stealth theme. A NACA duct right in the middle of the hood where the intake is would be optimal, but that would attract unwanted attention. While sitting stationary, the intake will suck up some of the warm air coming off the manifold/turbo. But I figure in first gear, the car will be traction limited anyway. Once the car is moving, I’m plumbing cool air towards the intake, so it should be sucking in near ambient temp air. We could possibly fab up an airbox to completely isolate the intake from radiator air, but I don’t think it’d be worth the effort.

That engine bay is looking mighty crowded, I don’t know if you could get some kind of snorkel to vent into the air filter like this:

https://www.s2ki.com/forums/s2000-modifications-parts-193/custom-piece-fipk-snorkel-pics-728433/

Yeah, I understand wanting a sleeper. I had my first car stolen within six months because I put some chromed aluminum 17” wheels on it. When I got it back (with some crap steel wheels) I used the insurance money to search for the lightest, yet stock looking aluminum wheels I could find. I eventually turned it into an auto-X car, but I was always mindful to remove the race wheels and slicks immediately before going home.

Because of that initial experience, I have always tried to make my street cars look understated. I absolutely subscribe to the ‘sleeper ethos’….because, as you say ‘life.’

I have to admit… I was eyeballing a Dodge Viper hood NACA duct… I talked myself out of it to stay under the radar. Some of the air from the driver side bumper duct will work its way into the engine bay. The passenger side bumper duct will be the primary way to plumb ambient air to the intake. When the front bumper is fully mounted, there may be a gap between the top of the heat exchanger and the top of the bumper opening. If so, we can make another air diverter plate to force air to go over the top of the radiator like the snorkels.

Great build! Is the turbo manifold available for sale? Ready to purchase

I’m waiting to get my car tuned to determine the wastegate performance before I sell the one spare manifold. I’ve been driving it around, making sure all the small things are in proper working order before going in for a tune. I’m hoping to have it all ready by the end of September.