,

We used Earl's Autoflex hose to plumb our oil cooler. It has a textile braid reinforced synthetic rubber inner liner and a tough braided stainless steel outer cover. The hose can withstand up to 300 degrees and 1500 PSI of pressure.

Drift cars get brutally hot, especially the engine oil on turbo cars. Drift cars have poor airflow over the front of the car as well. Both of these conditions make the need for a large engine oil cooler obvious. This Koyorad 25-row cooler will serve as the oil cooler and can hold up to 17 fluid ounces of additional oil. This will allow me to have greater peace of mind when I'm at the track. It was very frustrating having to take three or four cool down laps just for each lap of drifting.

Drift cars get brutally hot, especially the engine oil on turbo cars. Drift cars have poor airflow over the front of the car as well. Both of these conditions make the need for a large engine oil cooler obvious. This Koyorad 25-row cooler will serve as the oil cooler and can hold up to 17 fluid ounces of additional oil. This will allow me to have greater peace of mind when I'm at the track. It was very frustrating having to take three or four cool down laps just for each lap of drifting. The huge Koyorad cooler has ORB bosses for plumbing flexibility just like our power steering cooler. It also features bar and plate oven brazed construction like our power steering cooler. The tough bar and plate core can resists impacts from debris better than more fragile types of heat exchanger construction. This is a plus on a drift car.

The huge Koyorad cooler has ORB bosses for plumbing flexibility just like our power steering cooler. It also features bar and plate oven brazed construction like our power steering cooler. The tough bar and plate core can resists impacts from debris better than more fragile types of heat exchanger construction. This is a plus on a drift car.  The Koyorad high-density, 48 mm thick, triple pass radiator is optimal for the level of cooling we will be needing in this car with our higher power output.

The Koyorad high-density, 48 mm thick, triple pass radiator is optimal for the level of cooling we will be needing in this car with our higher power output. The Koyo radiator has all of the cooling bungs and mounts to be an easy direct bolt in.

The Koyo radiator has all of the cooling bungs and mounts to be an easy direct bolt in.  The Koyo radiator comes with a 30% higher pressure cap which improves cooling efficiency by reducing local boiling inside the head as well as raising the boiling point of the coolant.

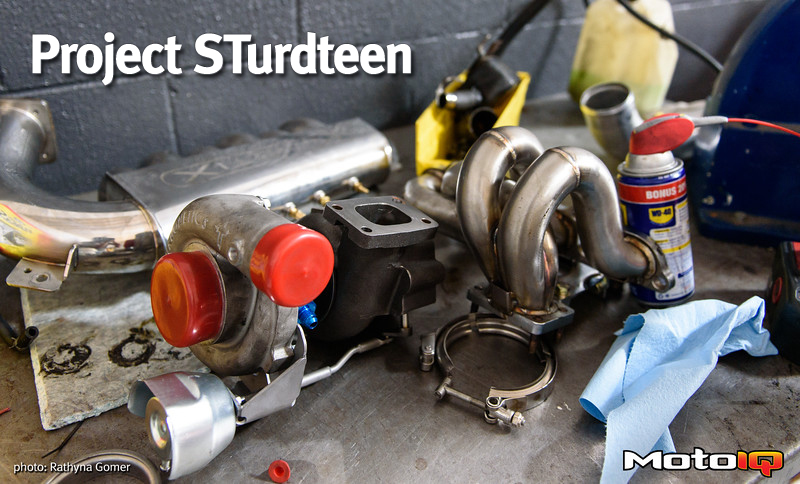

The Koyo radiator comes with a 30% higher pressure cap which improves cooling efficiency by reducing local boiling inside the head as well as raising the boiling point of the coolant. Before installing the cooling components, Howard Watanabe went through and began test fitting the new turbo manifold to make sure we didn't run into any fitment issues when we take the car to get the downpipe and intercooler piping fabricated.

Before installing the cooling components, Howard Watanabe went through and began test fitting the new turbo manifold to make sure we didn't run into any fitment issues when we take the car to get the downpipe and intercooler piping fabricated.  The first thing Howard did was to remove our stock turbo and stock cast iron exhaust manifold in anticipation of fitting the Turbonetics TNX20/52 turbo and ISR Performance stainless steel header we described in our earlier article. Out with the old weathered turbo!

The first thing Howard did was to remove our stock turbo and stock cast iron exhaust manifold in anticipation of fitting the Turbonetics TNX20/52 turbo and ISR Performance stainless steel header we described in our earlier article. Out with the old weathered turbo!