,

All the edges have been smoothed out.

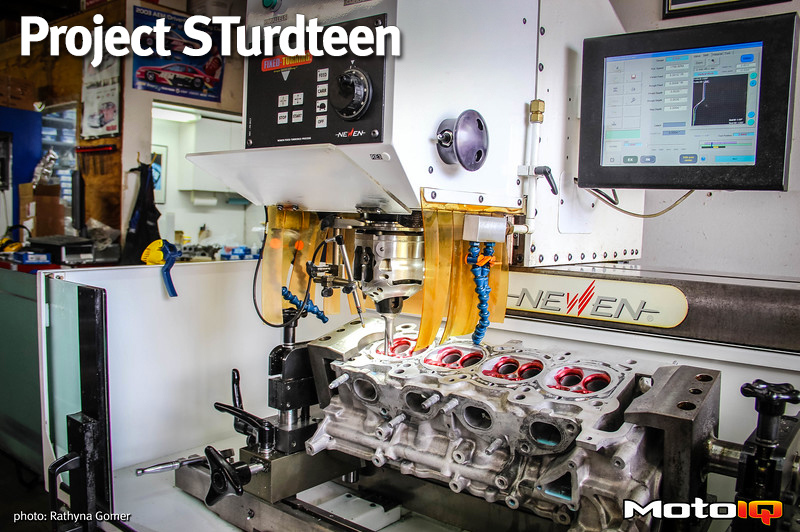

Tom is double checking everything and leak checking the head's newly cut valve seats.

All the numbers are checking out! The seats hold pressure.

My freshly rebuilt SR20 head is finally ready to take back to the MotoIQ HQ to install the valves! At our HQ, Howard Watanabe will blend the ends of the Newen cuts into the port and the chamber to give my head nearly the same flow gains as a fully ported head.

A big thank you to Tom Fujita for the awesome head work on my SR20. The valve job will give me just enough extra reliable power, which is ideal for a drift car. A valve job is one of the easiest and most efficient ways to make some more power without throwing any extra parts at your engine. Stay tuned as we continue on this SR20DET drift engine build!

Sources:

Portflow Design

Supertech

Progress Group

KW Suspensions

Parts Shop Max

AEM Electronics

Wiring Specialties

Mackin Industries

Andy's Tires

Koyorad

Turbonetics

HPS Performance Silicone Hoses

Earl's Performance Plumbing

Aeromotive

DeatschWerks

Jim Wolf Technology

ISR Performance

Enjuku Racing

Cusco

KBD Body Kits

GS Werks

3 comments

This is another project that vanished I wish we could see again

Questions!, who made the valves or how were the valves made for the newen cut seats?

did you read the article at all?