,

During my brake testing, I used the Fluke thermal imager for another test related to thermal management; i.e. how to get more heat out of the engine bay. The cooling systems for the coolant and oil are sufficient now, but if I want to add more power, I’ll need to improve cooling another step. One way to improve cooling is to improve heat extraction from the engine bay. A great location for that is through the hood.

|  |

Here are two shots of the front hood. Again, reflective surfaces can cause issues, so ignore the funkiness created by the shapes of the fenders and the top of the hood at the base of the windshield. What’s clear is the warm location in the middle of the hood. That probably would make a good location for hood vents. Just sayin.

After I finished using the Ti32, Wes borrowed it for use for the last race of the MotoIQ Pacific Tuner Car Championship. Tire temperatures were measured, brake temperatures checked, and something interesting relating to an exhaust header.

|  |

Here is a look at Rockwood’s and Martin’s Project G20 Racecar tires. On the left, the tire is cooler in the middle (~122F) than the shoulders (~135F). This could be due to a low tire pressure and shows a possibility of the tire not being used optimally; I’m guessing this is a front tire as Wes captured the image. In the picture on the right, the one shoulder of the tire is much warmer than the rest of the tire; the shoulder is around 130F with the rest of the tire at around 100F. The other shoulder of the tire is a little warmer than the middle of the tire. Considering the overall cooler temp of this tire, I’m guessing it’s on the rear. I wonder what optimization can be done?

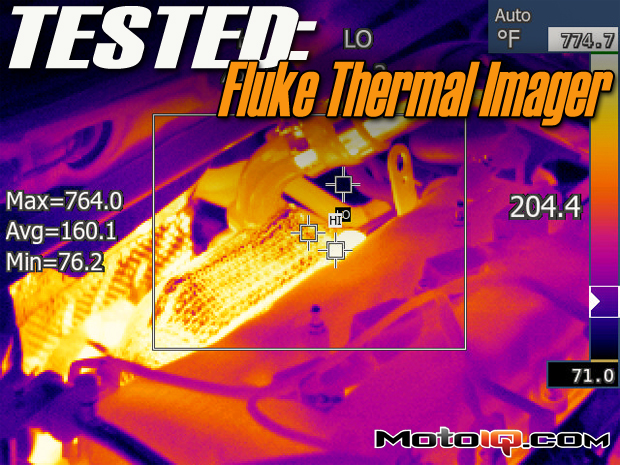

This is a look at one of the primaries of the header on the Dog car. Mike, Costa, and Wes were trying to analyze what was going on. The hot band is a weld joint which shows significantly hotter than the rest of the primary tube. We’re not exactly sure what’s going on there. Remember, the fundamental principle of operation of the thermal imager relates to the emissivity of the material the imager is viewing. The variable of angle of incidence probably comes into play too. My hypothesis is that the roundness of the weld is creating some funky angles of incidence making it look like a hot spot in the same way the outline of the primaries look hot. I’m still learning this thermal imager stuff, so feel free to chime in!

One more image off of a Porsche 911 Cup car from the North American Festival of Speed. There are a number of things that are in contrast to the images taken during my brake testing. On the Porsche, the brake caliper is also very hot and the wheel looks pretty darn toasty too. Even more interesting is that the entire tire looks warm as indicated by the sidewall. I guess that’s what a lot of time on track will do, which is to heat soak everything!

We only had a couple days to use and experiment with the Fluke Ti32 thermal imager, but we learned a lot in those few days. A thermal imager can be a very powerful tool for use in trackside testing and vehicle setup with a key aspect being the speed and detail of the information provided. It also can provide information to be used in the development of a track vehicle and vehicle parts themselves such as heat exchangers. I have a few more ideas for usage of the thermal imager, but I ran out of time to try them all out. It really is a great tool to have in a motorsports and vehicle development environment.