,

|

| A dry carbon dash saves a bunch of weight. |

|

| The SR20DET pumps out 800 ps @ 8000 rpm which is about 680 hp. It also makes 580 lb/ft of torque. This is one stout SR20! The internals use a 91mm Brian Crower stroker crank. The 87mm forged pistons are made by CP to Brian Crower's specs. The pistons are hung on Brian Crower I-Beam rods. The bottom end displaces 2200cc. The SR20VE 20V cylinder head is ported with big valves done by Nagoya Precision. The cams and valvetrain are also by Brian Crower. The VE's variable cam duration and lift is good for over 50 lb/ft of torque in the midrange over the simple variable cam phasing of the intake cam found in the DET. The 20V is the last SR varient of cylinder head and it has better water jacketing and the best port layout of all the SR20 heads. |

|

| The turbo is a Garrett GTX3582R. It has a ball bearing center section and the new super efficient GT35 based GTX billet compressor wheel with a .82 a/r exhaust housing. This turbo pumps out 33 psi controlled by a Blitz SBC boost controller. You can see a bit of the hand made stainless 90mm downpipe. |

|

| A compact but high flowing Turbosmart Hypergate 40 wastegate is used. This wastegate is becoming the wastegate of choice among Time Attack cars due to its reliability and compact size. The tubular turbo manifold is made by Scorch Racing. |

|

| To ensure oiling at high rpm under high g's a dry sump system is used. An Advance Black series alternator provides electrical power. An ATI balancer reduces the bad effects of crank harmonic whip. Check out the swirl pot on the coolant line. This de-aireates the coolant helping keep things from getting too hot. |

|

| The dry sump system is plumbed with Earl's Pro-Lite light weight nylon jacketed hose. Crimp on Ultra Flex fittings save weight over the much heavier screwed together AN fittings that are usualy used to plumb race cars. |

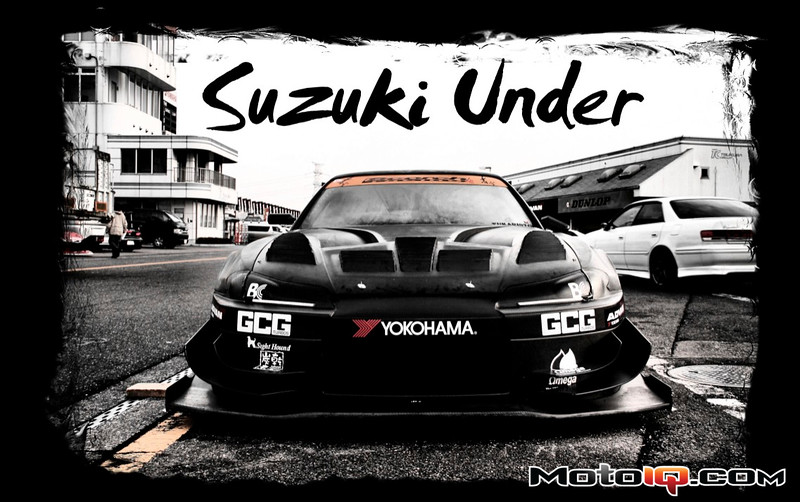

By the time you read this article, the Silvia will already be in a container on her way to Australia, still unfinished. Over the last two months Suzuki-san made some serious aero modifications. So far the front end of the car was all dry-carbon and rear end – wet carbon. Suzuki is making the parts himself and it is a painstaking process. Front parts took about half a year to complete. Keep in mind he goes to work from 9 to 5 every day, every week, just like everyone else (he’s a Pharmacist) and builds the car in the after-hours. He is truly a time attack otaku, all drivers and tuners who know him say the same thing about him, with respect – he’s a maniac.