,

Where the Newen machine differs from traditional valve machines is that it is a CNC machine that doesn’t use stones or a piloted cutter to make the valve seat and angles.

Where the Newen machine differs from traditional valve machines is that it is a CNC machine that doesn’t use stones or a piloted cutter to make the valve seat and angles.Here Tom programs the Newen to cut our valves seat and contours. The CNC machine uses a fly cutter and has infinite flexibility on how valve seat angles and widths are cut. It can also cut any angle for the approaching and exiting contours of the area.

The big advantage the Newen has over old valve cutting machines is that it can cut continual smooth radiuses over the whole valve seat. No individual angles that can cause turbulence and flow separation here. This used to require a lot of laborious hand work.

The big advantage the Newen has over old valve cutting machines is that it can cut continual smooth radiuses over the whole valve seat. No individual angles that can cause turbulence and flow separation here. This used to require a lot of laborious hand work.The Newen can also concentrically open the seat for more flow area and blend it into the port wall. It can repeat this exactly the same over all of the cylinders on every valve seat. This is impossible with hand work no matter how skilled the artisan prepping the head is.

Tom does a final check to make sure the head is mounted in the Newen correctly before starting the program.

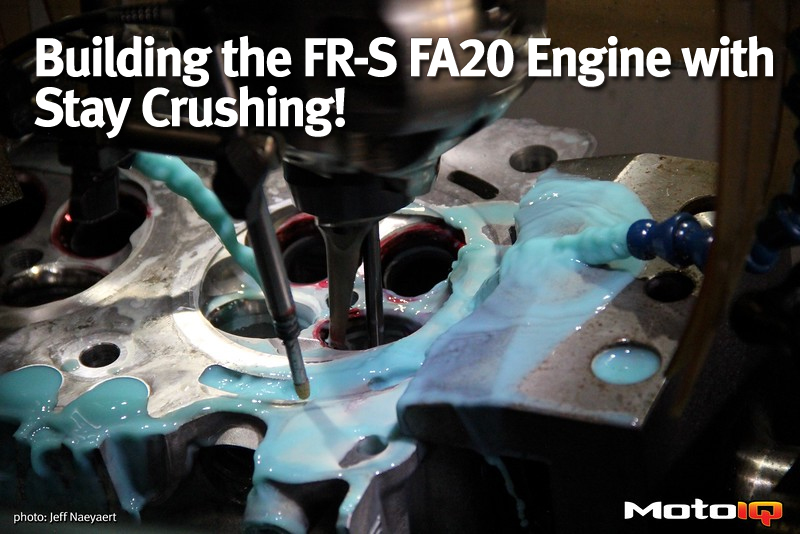

Tom does a final check to make sure the head is mounted in the Newen correctly before starting the program. As the Newen starts to make its cuts, Tom adjusts the coolant flow to land right on the seat. This improves tool life and helps give the best possible finish.

As the Newen starts to make its cuts, Tom adjusts the coolant flow to land right on the seat. This improves tool life and helps give the best possible finish. The Newen goes to town and cuts all of the valve seats.

The Newen goes to town and cuts all of the valve seats. Not only does the Newen cut the seats but it also blends the steel valve seat into the combustion chamber and the port wall itself.

Not only does the Newen cut the seats but it also blends the steel valve seat into the combustion chamber and the port wall itself.Normally there are big steps between the seat and the chamber and port as a part of normal production variance and removing these steps greatly helps improve the flow. This had to be done by hand in the past but the Newen quickly and consistently does this better than any person could possibly do.