,

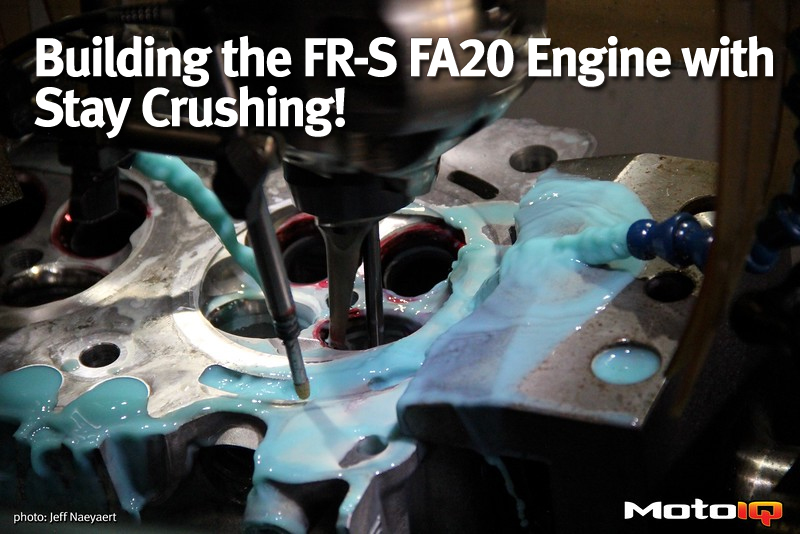

To finish off our heads, we did the final blending of the combustion chamber and the bottom cut into the port by hand. Even with the awesome Newen, there are small steps left in the combustion chamber and port where the cutter starts and stops.

To finish off our heads, we did the final blending of the combustion chamber and the bottom cut into the port by hand. Even with the awesome Newen, there are small steps left in the combustion chamber and port where the cutter starts and stops.These small steps are due to the production variance and core shift of the casting from port to port. The steps are small and back some from the areas of highest velocity but they should still be blended in. Even the Newen can’t make up for the variations in the head castings.

To finish off our heads, Howard Watanabe first taped off the deck surfaces of the head to protect them from damage.

To finish off our heads, Howard Watanabe first taped off the deck surfaces of the head to protect them from damage. Howard then placed the stock valves in place to protect the valve seats from any scratches while he blended the top cut into the combustion chamber.

Howard then placed the stock valves in place to protect the valve seats from any scratches while he blended the top cut into the combustion chamber. Howard used a pneumatic die grinder and a sandpaper cartridge roll to carefully blend the top cut into the combustion chamber.

Howard used a pneumatic die grinder and a sandpaper cartridge roll to carefully blend the top cut into the combustion chamber. The trick is to just break the edge of the top cut to the chamber and to remove the minimum amount of material to do so.

The trick is to just break the edge of the top cut to the chamber and to remove the minimum amount of material to do so. Next, Howard blended the step of the bottom cut into the port wall to make a perfectly smooth transition to the port.

Next, Howard blended the step of the bottom cut into the port wall to make a perfectly smooth transition to the port.Howard also smoothed the edge on the short side radius leading into the valve seat. Howard has really steady hands, if it were us, we would use some tape to cover the valve seating surface! These small tricks give our heads much of the flow gains off a fully ported, race-prepped head for a fraction of the cost.