With today’s technology, the power levels of modded street cars is going up and up. When the power goes up, the drivetrain has to support it. The first part of the drivetrain that has to deal with newfound power is the clutch. Previously when increasing the torque capacity of a clutch, the clamping pressure of the diaphragm spring was increased. The friction material of the disc was also replaced with material with a higher temperature tolerance and a higher coefficient of friction at elevated temperatures. Finally, the surface area of the friction material was reduced to put a higher load per area of the more aggressive friction material. The result of this was a clutch that could take more torque before slipping but as side effects, it also meant a super high clutch pedal effort and a light switch on and off engagement that was difficult to drive. Other side effects were really rough engagement with a lot of shaking and juddering that is annoying and hard on the rest of the drivetrain. Enter a more modern take on how to produce a clutch with more torque capacity while keeping things driveable, the twin or even triple-disc clutch. Multi-disc clutches have a very similar clamping load to the stock clutch but gain their torque capacity by having multiple discs, two or even three times the surface area as the OEM clutch. This is easy on the leg. The typical race-type multi-disc clutch is very noisy, the floated plates and discs all bang around when the clutch is disengaged making clanking and ringing noises and the clutch still has an on-off engagement and can chatter. Enter McLeod who has succeeded in making a quiet, easier-to-drive multi-disc clutch that is happy both on the track and on the street. The McLeod Mag Force SE is designed for mixed use and we are going to be giving it the ultimate test by installing it on an E46 M3 with an SMG semi-automatic transmission. Will the computers controlling the SMG freak out or is the MagForce SE streetable enough to be compatible with the SMG system?

Let’s look at what makes the Magforce SE streetable. The main thing is the clutches floater plate and pressure ring being strap driven. The strap drive is just like what holds the pressure ring in place in a conventional pressure plate. Normally in a multi-disc clutch, the floaters and pressure ring are allowed to bang around freely, this is what contributes to the characteristic noise of a multi-disc clutch. In the MagForce, the floater is held by the drive straps and can’t bang around. The next thing the drive straps do is to allow for a progressive engagement of the discs. In a typical multi-disc clutch, all of the discs and floaters get their clamp load from the pressure plates diaphragm spring at once. This causes a lot of grip in the system instantly and you get an on-off engagement of the clutch. With the drive straps on the floater and pressure ring, first, then as the drive strap for the pressure ring compresses, the bottom of the pressure ring and the upper disc come into play. As the strap for the pressure ring flattens out, the bottom of the floater and the lower disc retained by the drive strap with less bend start to engage next. This gives a smoother more progressive engagement. In this picture you can see the drive strap, it is the leaf-type spring attaching the pressure ring to the top of the pressure plate cover. You can also see the drive strap on the bottom of the floater attaching it to the flywheel The top drive strap has a bend and the lower one is almost straight. This difference in touchpoints that this makes results in a more progressive engagement.

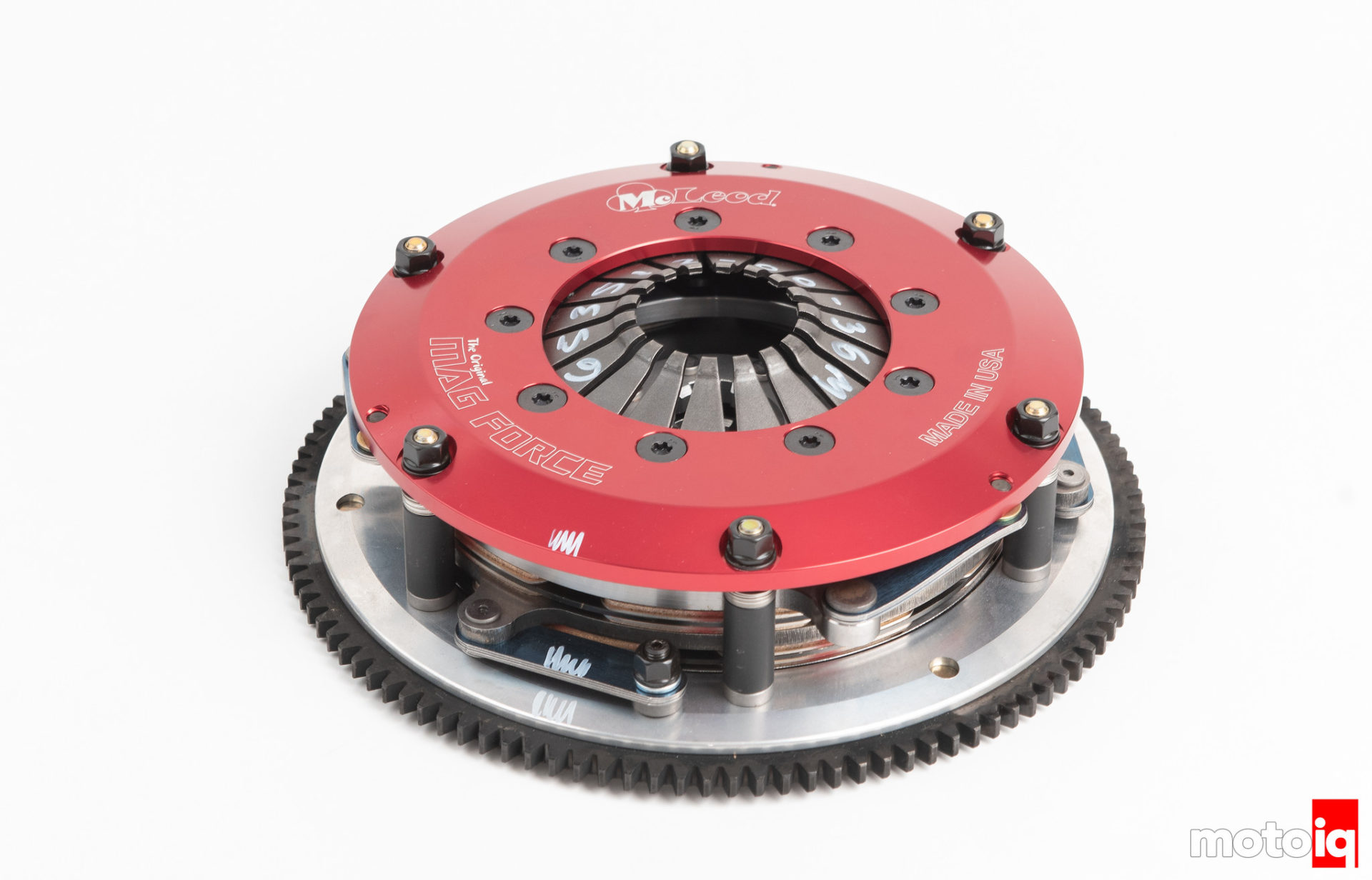

The MagForce SE also comes with a lightweight aluminum flywheel. The tall stand-offs are to hold the top of the pressure plate while the shorter studs are the anchors for the drive straps for the floater.

You can see how the standoff and studs installed height can be adjusted with shims. This is used to accommodate clutch discs of different materials and thicknesses. You can also use small shims to compensate for system wear through the life of the clutch to keep the clamp load consistent as things wear and get thinner. Since a multi-disc clutch has way more wearing surfaces, this is more critical than a single disc.

7 comments

Great article Mike. What do you think of this clutch compared to the X-Clutch twin-disk you spotlighted for the Project STI update a few months back?

Both seem to offer some pretty clever solutions to eliminate noise and offer a smooth street driving experience.

The X= Clutch is slightly smoother and this clutch is more heat resistant

Awesome, thanks for the info!

clutch noob question. Can someone explain the straps to me? whats the point of having a strap vs ditching the straps and connecting directly with a bolt or through shaft?

Straps = less noise/rattle and generally smoother engagement.

I mean I know that part, but I wanna know how and why, what about the straps makes it smoother vs no straps. I mean its still a direct connection them being metal straps… or are they like spring steel so they have give vs a bolted connection?

This