,

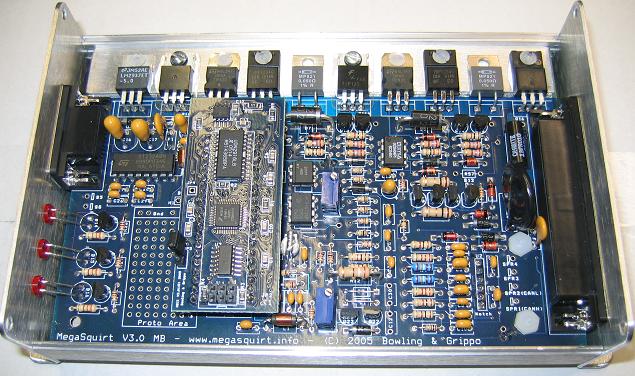

Obviously, the factory ECU won’t handle the idea of not only supercharging the KA24E, but even engaging the secondary injectors. If I did, It would end up looking at me like I’m stupid, then kill the engine as punishment for asking so much. So, I will have to use a new engine management system. There are many ECU options on the market, but if you couldn’t tell by now, I’m cheap! Fortunately, I also like to work in order to make something cheaper, so instead of those fancy, big label, “it’s already done for you” ECUs, I’ll be turning towards the Bowling and Grippo MegaSquirt DIY ECUs. With three versions now on the market, I will be using MegaSquirt II with board revision v3.0 as this one will allow for spark and fuel control with only a minor modification that will be well documented.

|

| The best DIY ECU you can buy currently, the Bowling and Grippo Megasquirt II V3.0 board. Mine will also include the Relay Board for easier hook-up and less risk of blowing everything up. (Picture care of DIYAutotune.com) |

Keeping with the DIY theme for electronics, I will also be creating my own gauge system using an Arduino Uno microprocessor. It will feature speed by GPS signal, G-force reading, and engine monitoring with all outputs logged on a SD card. The User Interface, or the gauges if you want to keep it less geeky, will consist of LED indicators and a LCD screen that will display to the driver RPMs (using LEDs for Shift Lights), Engine Temperature, Fuel Level, Vehicle Speed, Rear Wheel Speed, and O2 Sensor output. I will document the build of this and will hopefully show what companies like RLC, Racepak, and others have to do to make their stuff work and explain why these products cost as much as they do despite the low cost of the materials.

|

| I started out with this idea, pretty simple… |

|

| This is what I have ended up with. Still simple, but I like it better! |

I will also be borrowing a bit from Ford before the V8 swap, an 8.8″ IRS Style rear end from a MN12 89-94 Ford Thunderbird. The 8.8″ rear is not only tough, but since it is the same 8.8″ that came in many Ford products, including most trucks, it has a vast aftermarket and that means cheaper parts! Only one problem, the S12 comes with the long nose versions of the R differentials. The one that came in the CA20E powered S12, like mine, was the R180, nobody makes parts for them, unless you swap to Subaru WRX STi internals. Even then, it’s not so easy or cheap.

|

| Cheap, strong, and parts are plentiful and thus, cheaper! The 8.8″ IRS looks good the more I look at it! |

The long nose R200 that came in the SE V6 S12 is the same internally as the R200s that came in the S13, 14, and 15. More parts are available, but still not cheap and I have yet to find aftermarket Ring and Pinions outside of NISMO. The 8.8,” on the other hand, has ring and pinion options that are not only inexpensive, but plentiful! Want a 3.02:1 ratio with a limited slip, you got it for less than $1000! Want a 5.14 ratio with a 31-spline mini-spool? You can get it for less than $400. Want to use a different yoke? You’ve got options and I can go on. Better axles and a one piece driveshaft that will all fit are all a call to Standard Auto Parts, who make custom shafts for not much money. My only concern will be making an adapter that will allow me to use the rear mustache bar with the short nose of the 8.8,” but I don’t foresee it as a problem.