I just removed the end cap, attached the EAS power switch, and reinstalled the end cap. I’d secure everything later once I figured out how long the extensions needed to be.

I temporarily installed the half-hacked harness so that it would be roughly in the place it would live, and then I took some measurements to figure out just how much I needed to extend the harness by. I started by attaching the relay in the engine bay as I did in part three so that the power and ground wires would reach the battery. I then ran the rest of the wires down around through the engine bay and tried to stay clear of the steering column.

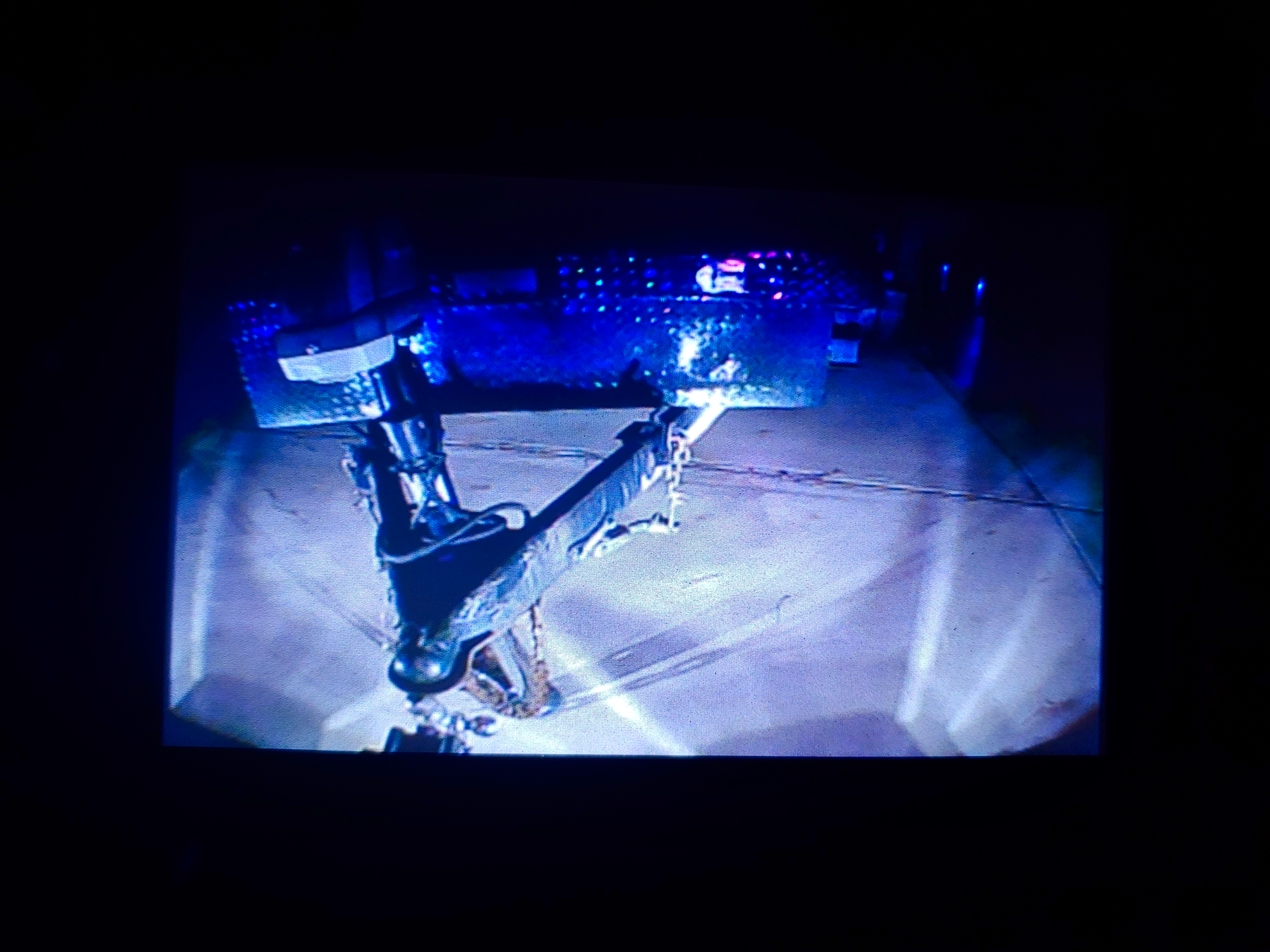

I shoved that under the van and pulled the tape along the route the wires would likely take and measured that. I then padded a bunch to the numbers, just in case, and used that for my extension cuts.

And, since I knew that I was going down the driver side of the van and one light pod would be on the passenger side, I made one extension longer than the other.

Whatever you do, do not use the ghetto bullet connectors that you can find at the auto parts store. They will find the most inconvenient time to separate. Either parallel splice or use a solder joint, but solder has no business connecting wires on vehicles.

2 comments

you blanked out the back of the plate but then left the actual plate numbers visible on page 8

Yeah I realized I forgot to blur some of them a little bit late, and the way our photo system is set up I can’t delete photos, and it’s not hard for someone to just go to the whole photo gallery, so even if I added new blurred photos the old ones would still be there for now, so I just left them.

Thanks for noticing, though! =)