,

|

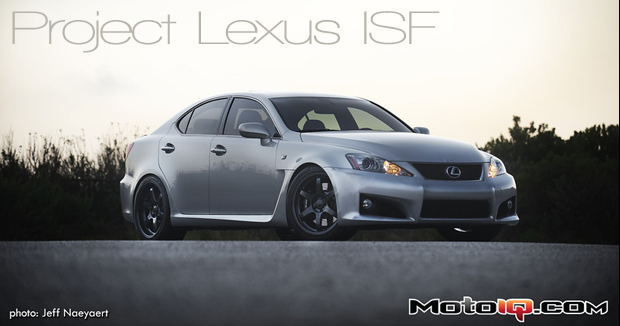

Tires are one of the most important links in the handling chain so we definitely had to upgrade our worn all season radials. Replacing the IS-F's worn out stock Michelin Pilot Sports with something good was going to be tough since that is one of the best dry performance tires on the market. Since we like the Nitto NT01 race tire a lot, we chose its street going sister, the Nitto NT05 Ultra high performance street tire for our IS-F. We had also really liked the NT05 in our testing last month. The Nitto NT05 is the end product of several years of intensive R&D testing, burning rubber at several proving grounds and three different racetracks including the famed Nurburgring. Nitto’s testing focused on balancing the ultimate in dry handling performance with long tread life although our testing has shown that the NT05 is not bad in the wet either. A big part of the R&D testing for the NT05 involved dialing in the composition of the NT05’s unique tread compound. The compound developed for the NT05 uses a lot of silica and a special blend of polymer additives to create a flexible and resilient tread material that is very good at conforming to micro irregularities in the road surface. This tread compound works exceptionally well in both wet and dry conditions and is a big step forward in grip capability when compared to the long wear biased compound used in older Nitto tires. |

|

The NT05’s carcass is also designed with ultra high performance in mind. The tire's casing is made of two plies of polyester with a high end turn-up. The turn up refers to the turn of the plies as they go around the bead of the tire and back up the sidewall. High turn up means that the termination of the plies is higher on the sidewall than normal giving the sidewall 3-4 plies of stiffness from the bead to the tread from a two ply casing. This stiffens the sidewall in the bead area, improving handling by quickening response to steering input while still allowing the sidewall to flex a little in the tread area for smoother ride and layout of the tread to the ground plane for better grip by reducing sensitivity to tire shock. Two steel belts increase puncture resistance and reduce tread squirm, helping keep the tread flat on the ground without lifting under side load when the sidewalls distort. A spiral wound aramid (aramids are super strong synthetic fibers like kevlar) cap ply prevents tire growth and tread center bulging at high speeds, reducing heat build up and improving the tire's speed rating. The spiral winding eliminates the need for the typical way of joining the cap ply, a lap seam which is a weak spot under load and an area of differing stiffness that can cause problems at high speeds. We selected a 245/40-19 tire for the front and a 275/35-19 for the rear. We wanted the taller front sidewall for more airdam clearance as the car is a daily driver. This is up from the stock 225/35-19 and 255-35-19 tires. |

|

Since our IS-F is an expensive performance luxury car we chose one of the best wheels on the market for it: the Volk G2 made by RAYS. Since there is a lot of debate lately on the validity of expensive wheels over cheap wheels, we will explain some of what goes into the engineering of a high end wheel like the Volk G2. RAYS' use of extensive analysis in design and state of the art manufacturing technology make their wheels double the standard strength, and ensures that each wheel is up to the best quality standards. That sort of engineering is important to us; after all, the wheel is a critical component for safety. RAYS uses extensive FEA analysis to optimize their designs. Those familiar with analysis know the analysis is only as good as the inputs. This is where RAYS’s participation in F1, WTCC, Super GT, and American Le Mans is critical. RAYS has a database full of test data that has allowed them to accurately provide the inputs into their analysis for wheel design. The result? The analysis closely matches the results of actual product testing. The accuracy of RAYS’ analysis package allows them to rapidly develop new wheels as they are able to go through many design iterations quickly. To be the best, you have to go beyond the standard, so RAYS developed their own strength and durability standard, JWL+R, based on Japan’s JWL Intensity standard for aluminum wheels. JWL+R parameters for endurance and weariness trials are twice as severe as the JWL standard. Additionally, JWL+R perform a shock trial with heavier weights. Even though RAYS wheels are very light, you know they are super strong! |

|

| To create light, yet strong wheels, RAYS has developed multiple manufacturing processes to achieve this goal. For the ultimate in performance, RAYS creates its forged wheels with a forge press that forms the metal in 3 to 4 steps with 10,000-tons of pressure! Another RAYS exclusive process is RM8000, using open-die, spin forming technology. Lastly, there is RCF, RAYS Cast Flow Forming process; RCF applies spinning technology to the casting process to provide relatively lightweight cast wheels with great strength. And just so that you know each wheel is high quality, RAYS has ISO9001 certification and TUV marks for various European market products. Forging refines the grain of the metal though a phenomenon called cold working which improves the strength and other mechanical properties. Like wood, metal also has a grain and the forging process aligns the grain to the geometry of the part which also imparts strength and durability. Forging also increases the metals ductility meaning that if the wheel is subjected to a catastrophic impact, the forged wheel will most likely bend and retains most of its structural integrity instead of cracking or shattering like a cast wheel probably will. The MotoIQ crew has found Volk wheels to be very durable despite the light weight. When subjected to the rigors of racing, (nearly all of our staff have racing licenses and race actively) Volks outlast cheaper lightweight wheels at about a ratio of 4:1. The MotoIQ crew has also never suffered a wheel failure with Volks that caused the loss of air pressure or a debeading of the tire, even in serious racing accidents where wheels were destroyed. |

|

| The strength imparted to these aluminum wheels by the patented RAYS forging process enables the G2 to have thin spokes with a thin profile for light weight. Notice the weight saving pocketing around the hub and the backsides of the spokes. The rim section is as thin as 3.5mm in places while still being strong. The G2's are thus about 4 lbs lighter than the stock wheels even though they are wider. We used a 19x 8.5 front and a 19 x 9.5″ rear wheel. |

|

| A high end car with high end wheels deserves a high end install. So many horror stories are in every car forum about indifferent tire stores scratching wheels and messing up high end cars with a shrug of the shoulder. This would not go for us so we invested a little extra and had ASAP Tires mobile service mount and balance our wheels. ASAP understand that your car is expensive and your wheels can be scratched and takes care with your stuff. ASAP has experience handling exotic and lowered cars with no damage as well. |