,

Making this a sub-harness aids in installation later on. We selected switches that use ring terminals when possible to add reliability. However, this would have meant trying to use a screwdriver on tiny screws and likely having to remove the switch panel any time harness work was done.

This sub-harness ties the dashboard switch panel switches (excluding the kill switch and the Racepak SwitchPanel) into the main harness. It was designed separately for the same reason as the kill sub-harness- to aid in installation.

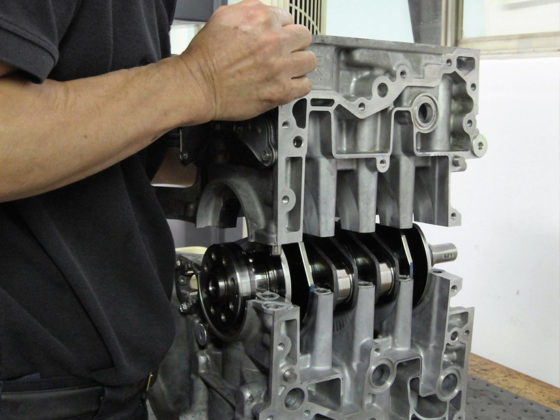

This engine bay harness includes all of the lights and other power distribution as well as some additional sensors. The Haltech plug-and-play 2JZ harness did not have oil temperature or brake pressure sensors on it, and so these were added. The Elite 2500 added provisions for up to two knock sensors, and so these were also planned for.

The main engine bay harness also includes two control signals: one for the cooling fan relay and one for potentially a future ABS system power relay. Cooling fans can draw quite a bit of current. In some cases, more than the 20A that the Racepak can provide. A remote relay/fuse unit will be used in the front corner of the vehicle and one of these signals will actuate it. An ABS solenoid, as well, can draw significant power. So, it will also have a dedicated remote system.

I could have used multiple Racepak Smartwire outputs tied together to provide the current capacity for these devices, but I did not want to use up all of my outputs for a relatively small number of systems- there are future things I might want to add. Again, this was a small compromise to keep the bigger picture in mind. It’s easy to lose the forest for the trees!

Haltech uses two AMP connectors on their ECU. Many of these were already in use by the plug-and-play 2JZ harness. Haltech originally accounted for quite a few important sensors when they designed the harness for the Elite 2500 ECU. However, the one drawback to using the plug-and-play harness is that, other than the few extra breakout connections they provide, other ECU functions were simply not connected. The new Elite series ECU adds additional functions that also were not accommodated by the plug-and-play harness.

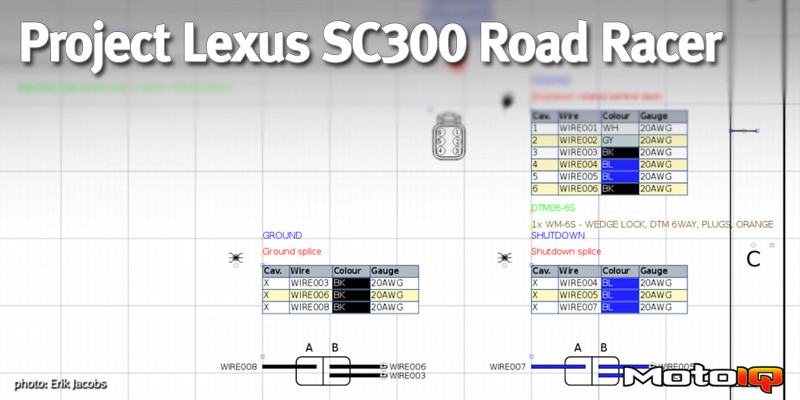

That brings us to the bridge harness design. The bridge harness is another sub-harness designed to make life easier. It exists for a few main purposes:

-

Provide a single connection to the rest of the cabin harness for the new sensors and signals instead of trying to run them all the way to where they are going.

-

Provide for future expandability via a spares connector that is wired into features and functions that are currently unused.

-

Break out the pulsed inputs that will be used for wheel speed sensors into a completely separate harness.

-

Break out the CAN bus to several connectors, one of which can serve as a diagnostic port.

Building this small bridge harness ensures flexibility, ease of installation, future expandability, and more. Everything could have been added directly to the Haltech plug-and-play harness as home runs- going directly from the ECU to the bulkhead and other places. It would have made the overall cabin harness a little harder to deal with, and we still would have had the need for the spares connector, pulsed inputs connector, and CAN breakout.

One thing that should be noted is that the Haltech Elite series ECU has evolved to use a dedicated signal ground for analog sensors, as opposed to referencing analog signals to chassis ground. We’ll talk about this a little more in the future, but it's suffice to say that using chassis ground for sensors is not optimal for a number of reasons. It’s nice to see Haltech adding this feature. It comes with the caveat, though, of having to run that sensor signal ground everywhere that you might need it. This meant that we needed to tap into the existing harness’ signal ground for both our “new” bridge connector as well as our spares connector, and you can see that in this harness design.

Another sub-harness that come from a circular mil-spec bulkhead connector on the transmission tunnel.

Another sub-harness that come from a circular mil-spec bulkhead connector on the transmission tunnel.We added one of Haltech’s WBC-1 wide band oxygen sensors to Project SC300. It does come with all of the wiring you need to connect it, but we wanted to incorporate it into our new wiring design. As such, this sub-harness will carry all of the oxygen sensor power and signals, as well as an input signal to detect if the reverse switch on the transmission is closed. Every race car needs reverse lights, right?