,

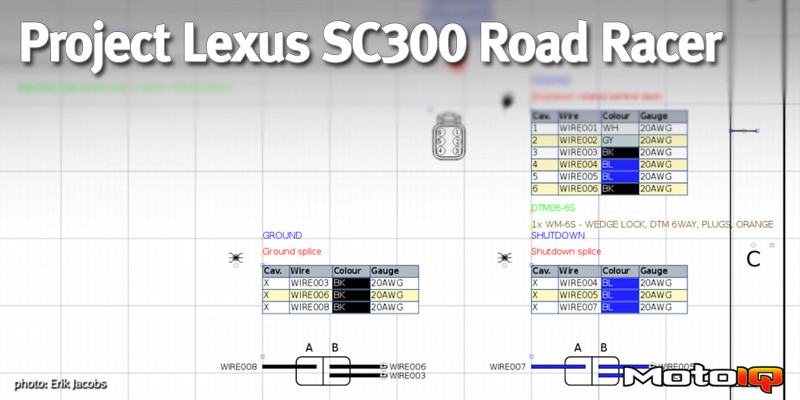

The trunk sub-harness carries power for the fuel pumps, lights power, and the fuel level signal. It’s relatively simple.

The trunk sub-harness carries power for the fuel pumps, lights power, and the fuel level signal. It’s relatively simple.The only caveat with the trunk harness is power capacity. The specifications for the circular mil-spec connector we are using state that the current handling capability for the #20 terminal is only 7.5 amps. If our fuel pump potentially draws 15+, that meant we needed at least two wires/pins dedicated to the fuel pump. This is cutting it close, but that’s the benefit of using sub harnesses and bulkhead connectors. If we have to remake a section of the harness, it’s not terribly hard. If we just have to add a single wire, we can run it along the main bundle after the fact. It would not be pretty, but it would work.

We are running the wheel speed sensor signals in a completely separate harness that has its own dedicated bulkhead connectors.

We are running the wheel speed sensor signals in a completely separate harness that has its own dedicated bulkhead connectors.In addition to being an isolated harness, we are using a special pre-twisted and shielded Raychem Spec55 wire for these signals. Since wheel speed sensor input could be used for traction control and may in the future be used for ABS, it is extremely important to try to minimize noise on these signals. Newer wheel speed sensors are powered and have various features to improve their function. These older Lexus/Toyota wheel speed sensors are a simple two-wire design that works reasonably well, but must be accommodated appropriately.

The main cabin harness is insane- just take a look at it. It requires an A0-sized frame to fit- that’s a 33” x 47” piece of paper!

It has 112 wires in it.

It has 36 connectors that are a combination of Deutsch DT, DTM, mil-spec circular, and ring terminals.

It connects to just about everything in the car, from the front firewall to the back firewall and everything in between.

It has 700+ feet of wire in it.

Almost every source and destination pair have multiple routes they could take to get there, requiring careful routing in the software.

This is where I spent countless hours and nearly lost my mind. I definitely lost sleep. I lost… a good portion of my life. It’s really hard to wrap your head around the fact that each source connector might have multiple destination connectors, but you want to try to run bundles of wires together in common. It takes a few inches off a connector before you can really split or join the bundles, and … and… I’m starting to get PTSDD (post-traumatic schematic design disorder) just thinking about it again.

But, in the end, I finished.

Except now I actually have to build it, and hope that it works right. No pressure.