,

Next to the power steering reservoir is a PHR resistor pack bypass, which is necessary for Supras running high-z injectors because they came equipped with low-z injectors from the factory. Getting rid of the ugly resistor pack also further cleans up this engine bay.

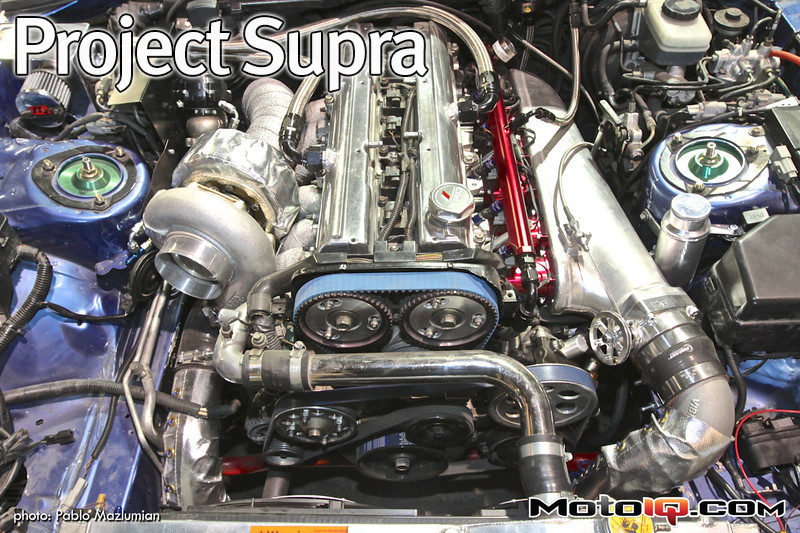

Looking further into the engine bay, a nice detail added by MKC was the painted aluminum heat shield to protect the ABS system from excessive exhaust heat. Everything is a tight fit, as you can see with the Precision Turbo wastegates, but they fit!

As featured in Part 6, Project Supra uses high performance belts from Gates, which are among the best in the business and even found on 10,000hp NHRA nitro cars (check out our technical discussion of those engines here!). But we had only featured the light blue timing belt, and now we have the accessory belt on as well.

As featured in Part 6, Project Supra uses high performance belts from Gates, which are among the best in the business and even found on 10,000hp NHRA nitro cars (check out our technical discussion of those engines here!). But we had only featured the light blue timing belt, and now we have the accessory belt on as well.

So why go through all of this trouble to run E85? Because we’ll be flex-fuel compatible soon, thanks to AEM’s latest Infinity Plug-and-play engine management system!

Going from an AEM Series1 EMS, which has worked great and hiccup-free since it first got installed on Project Supra back in 2003 (at AEM in-house, no less), we’re as excited as a tornado in a trailer park to get the AEM Infinity running on our Supra. We’ll have more on this soon, but in the meantime you can check out our latest Infinity EMS article on our Project E46 here!

If you've enjoyed some of the other MKC project cars we've featured in the latter pages of previous Project Supra and Project M3 articles, click on the last page to see what we found rolling inside their walls this time…