,

|

| Even though the Ford Coyote motor is a very modern all alloy V8 DOHC 4 valve motor, it is still very large. The LS is tiny by comparison and a little lighter. |

For those whose mods are dictated by logic and efficiency, the LS is a hard motor to beat as a swap candidate. The LS3 is not a dated redneck block of iron but a fully modern world class power plant designed with strength, rigidity, low pumping losses and light weight in mind. The design of the LS bottom end is now on par with what other world class manufacturers have been building for years.

|

| The Lexus 2UR-GSE as found in the Lexus IS-F is also a big and bulky motor. It would be much harder to swap than an LS. |

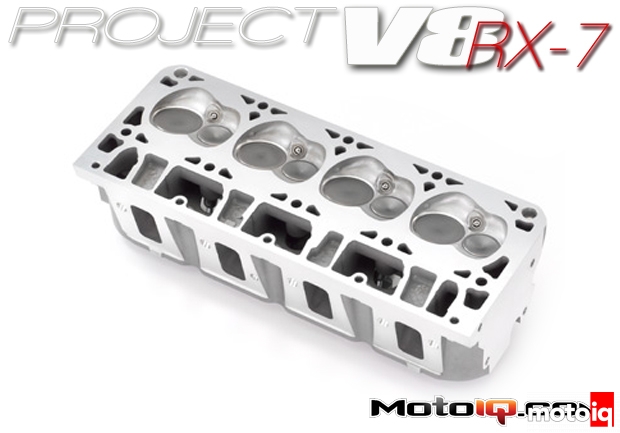

In this installment of Project V8 RX-7, we will take a look at the cylinder heads and top end of the engine. Yes the LS is a single cam two valve per cylinder engine with the valves operated with pushrods but it is far from being low tech or dated. The design has been thoroughly engineered and optimized. At first, a pushrod engine might seem lacking in sophistication when compared to the twin cam 4 valve per cylinder designs that are typical for higher end engines these days. For a moment, put aside your prejudice and consider that push rods have many compelling advantages that are quite appealing.

|

| This is a Nissan Titan VK565DE swapped into Chris Forsberg’s 350Z. Look at the tight fit. The VK56 is one of the lighter and more compact Japanese engines but it is still a big beast. |

|

| In contrast, look at the comparably tiny LS in Matt Powers S14. The LS is surprisingly compact which makes it a good swap motor. |

One advantage is that a push rod engine can be designed to be smaller and more compact. Twin cams and their operating parts make for taller and more bulky cylinder heads. The added bulk and complexity means that the engine is much bigger and heavier. The main advantage twin cams have are their lighter valvetrains which have a much higher capability for high rpm use, but modern pushrod engines are fine at rev limits that production architecture engines can be expected to run at, which would mean around 9000 rpm for a highly modded engine. A modified production based DOHC engine probably won’t be reliable at a higher rpm than that either due to piston speed limitations. Thus the lightweight DOHC valve train is not as much of an advantage except for perhaps a slight advantage in friction reduction.

|

| Even though it is a 1300cc Rotary, the 13B-REW found in the FD RX-7 is a complex and cantankerous beast that likes to blow up or catch on fire. The engine itself is not that big or heavy but by the time you add, twin sequential turbos, intercoolers and other peripheral things, it gets packed in the engine bay pretty tightly! |

|

| The LS1 we had in Project FD was a better fit than the stock engine! |

Related