,

|

| The difference between the old style rocker arm and the new style with the offset to clear the bigger intake port and larger valves. The stock rockers are roller bearing mounted which is a big improvement over the old small block Chevy sliding trunnion rockers. If you have ever modded an old school V8 you have probably grown up cursing these types of rockers if you had any sort of aggressive cam and tried to run some revs! |

The LS3 camshaft is fairly aggressive for an OEM application, with 267 degrees of intake duration with a whopping 0.551 lift with a 120 degree lobe center. The exhaust side has 275 degrees of duration and 0.525 exhaust lift on a 115 lobe center line. A 117.5 degree lobe separation angle keeps overlap fairly low for good emissions and a smooth idle. The roller lifters and the high rocker ratio give the fast valve action with a lot of area under the curve.

|

| Here are the offset LS3 rockers in real life! |

The wider and taller intake ports means that a new intake manifold also had to be designed. The intake manifold is made of glass reinforced nylon 66 with low thermal conductivity to help keep the intake charge cool. A unique lost core process is used for the molding process so the manifold can be molded in one piece, unusual for a complicated plastic part. The runners have better flow than previous versions of the LS. Metal inserts have been added to the bolt holes to prevent loss of torque and sealing due to the plastic material getting compression set. Larger injectors from the LS7 have also been fitted along with a larger 90mm drive by wire throttle body.

|

| These racing shaft mount roller rockers keep everything perfectly aligned and awesome. We run these in Dai Yoshihara’s drift car and they work flawlessly to 7400 rpm. Not bad for a 427! |

The exhaust manifolds are sealed with MLS gaskets and have the ports revised to match the heads. The iron alloy used is a high strength material with high silicon and molybdenum content, much like a turbo manifold which allows for thinner and lighter manifolds to be made, reducing overall engine weight by 10 lbs.

|

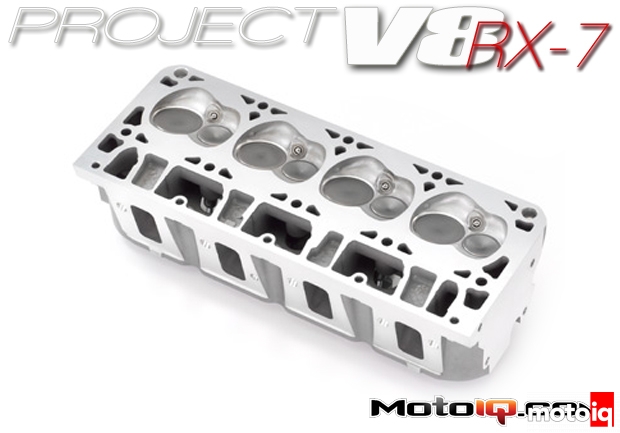

| A two valve head can have a lot of quench area and a fast burning turbulent combustion chamber. The LS3 takes full advantage of this and has tons of quench. This is a main reason why LS motors are so efficient and get decent fuel economy. |