,

|

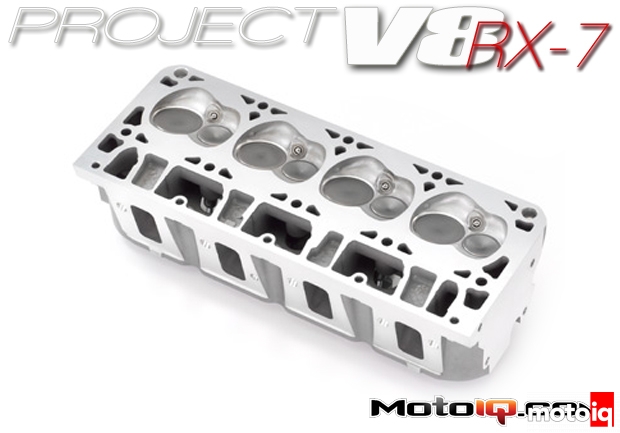

| This view looking down the intake port shows how straight of a shot the LS3/L92 intake port is. If you are familiar with the old small block Chevys, you could not even see the intake valve because of the convoluted flow path of the port due to the head bolts and push rods. |

Other refinements are improved deck sealing surface finish for GM’s new 5 layer MLS (Multi Layered Steel) gaskets. This sealing system is much more reliable over many thermal cycles. Thermal cycling can put a lot of side slip load on gaskets which causes gasket and sealing surface wear believe it or not. An ultra smooth sealing surface reduces this. MLS gaskets need super smooth surfaces to seal. The 5 layer MLS gasket was developed to improve sealing in situations where the head may lift giving the gasket system some springiness so it can continue to seal in the case of some localized lift.

|

| This shot looking up from the combustion chamber shows the generous short side radius of the LS3/L92 intake port. The fine sand casting core used on the ports leaves a good smooth surface finish which you can see here. |

Finally, the cylinder head oil drain hole geometry was optimized for better drain back. Moving the push rods over for the bigger intake ports had made the drain hole area get smaller and to ensure proper drain back this had to be redesigned. The valve cover gasket sealing rail was widened and strengthened after FEA studies showed that it was distorting in the old LS1 design causing leaks.

|

| This shows how much farther apart the valves are on the LS3/L92 head compared to the older design. This allows larger valves and a thicker bridge between the valves to avoid cracking. |

To maintain valvetrain geometry with more radical cams that required a smaller cam base circle, the LS3/L92 has longer valve stems, longer by 0.6mm. The cam uses friction reducing roller lifters with hydraulic lash adjustment that operate the roller bearing equipped rockers through pushrods. Roller lifters also can allow faster valve operation. The roller rockers are a big improvement over the sliding trunnions found in the small block Chevy. If you were ever into modding old domestic V8’s you know how lame the sliding rocker arms are! The rockers have a pretty aggressive 1.7:1 ratio; 1.6:1 is more typical.

|

| This shows how the pushrod was moved to accommodate the larger intake port and the bigger valves. |