,

|

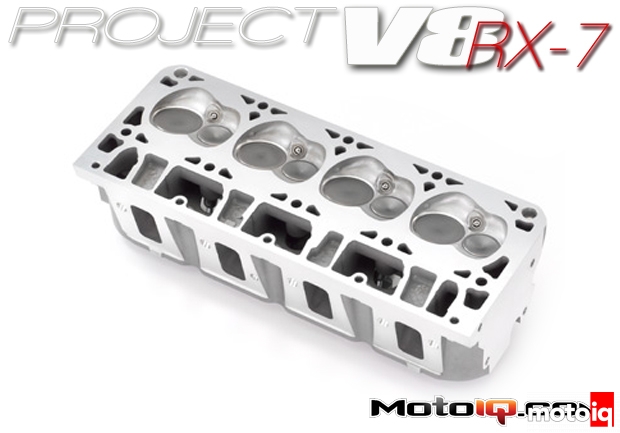

| Getting flow gains across the board is pretty hard, just ask any head porter. The difference between the new LS3/L92 head vs the older LS1/LS2 head are shown here. Outstanding results! The LS ports outflow many DOHC 4 valve heads. |

An advantage that a 2 valve combustion chamber can have over a 4 valve is that the chamber can have more quench area and more freedom for quench pad geometry so the mixture’s tumble and swirl can be increased. This means that if the chamber is optimized, you can have a more turbulent and homogeneous mixture for a very efficient burn. The LS3/L92 head has more quench area than the older LS heads and the area around the intake valve has been contoured for more tumble than previous designs as the piston travels away from TDC. These design features mean that the LS3 has a very turbulent chamber design that promotes a high degree of combustion efficiency. This combustion efficiency is why LS motors usually can have mileage in the mid 20 mpg range on the highway and sometimes even more! This is way better than your typical turbo 4!

|

| The LS3/L92 exhaust port gains are impressive as well. |

The LS3/L92 head has also received other design refinements over old LS heads. It was found that the rear freeze plug location on the LS1 heads was causing a weakness resulting in thermal distortion of the head sealing faces. To eliminate this, the plug was removed. The plug is also problematic in that it is a galvanic hot spot and easily corrodes. When it starts to leak it is impossible to fix it in the car as we have found out with project RX-7’s original LS1. For this reason alone we are very glad that GM has eliminated this issue.

|

| The LS1 head on the right shows the freeze plug that was deleted on the newer LS3 head on the left. This stupid plug is what launched our quest to put the LS3 in our FD to begin with. The plug rotted out on our old LS1 and the only way to replace it is to pull the engine. Deleting the plug greatly reduces heat induced distortion of the head. |

The conventional steel valve seats were replaced with a sintered material made of tool steel, molybdenum disulfide and infiltrated with copper for machinabilty and heat transfer. This is trick stuff, super long life even with unleaded fuel, excellent heat transfer and good machinabilty all in one package. If you have ever had to do a valve job with modern hardened seats, then experienced cutting seats with nickel bronze or other trick racing materials you will know what we are talking about!

|

| The LS3/L92 head has super trick valve seats. The seat is made by first sintering ultra hard tool steel with molybdenum disulfide together. This gives hardness and lubricity, important for long life. Next, copper is sweated into the porous seat for better heat conductivity, lubricity and machinabilty. The result is a valve seat that is easy to machine, yet wears a long time that has superior valve cooling properties. This is way better than aftermarket stuff! |