The Discount Tire/Falken S13 that Dai Yoshihara drove to many podiums and a Formula Drift championship now resides with Falken Tire where it does duty as a promotional demo car. The car was equipped with an LS crate motor for a while and last year it had gotten a brand new built motor from a well-known engine builder to give it some more steam for a demo at GRIDLIFE. Unfortunately, the new engine blew after just a few laps. The engine blew so badly that it was hard to determine the root cause of the failure. A rod went out the side of the block and the remaining bearings exhibited signs of oil starvation.

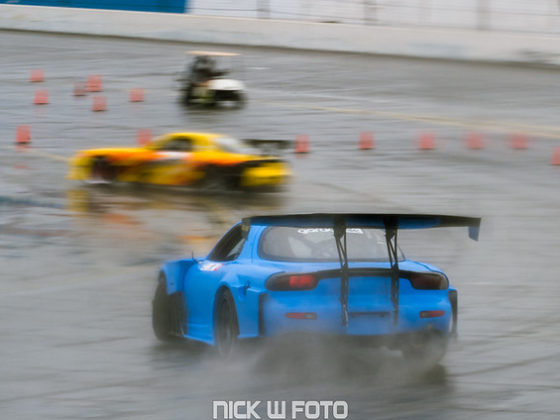

Well, demo motors are not supposed to make big power, just enough power to do spectacular demos and last a long time between rebuilds. Since our FD competition motors have gotten a good reputation for superb reliability at really high power levels, we asked Falken if we could get a crack at building the demo engine for this historical car. Since I had been the engineer for this car when it was competing it would be a pretty cool thing for me to have a crack at doing the restoration engine as well.

So our goals were to build an engine that would have close to or more power as the car had during 2010 season with bulletproof reliability. Most of all because the car was a demo, the engine would have to be built on a tight budget so cost containment was an important consideration as well.

Since the original block was destroyed we bought a new LS3 block from Scoggin-Dickey. Scoggin-Dickey is a Chevy dealer with a huge performance parts business and they have the best prices in town. The old motor had an older LS2 block that was sleeved and bored out to 4.125″ and when paired with a 4″ stroke crank, provides a displacement of 427 cubic inches. We don’t like using sleeves and have had bad experiences with sleeved LS engines, having the sleeves sink in FD competition many times. An LS7 block that comes with a 4.125 bore is a lot more expensive so that put it out of budget as well. The LS3 block has a bore of 4.065″ which would make our displacement 415 cubic inches with a 4″ stroke. This was smaller than the previous engine but bigger than the 402 cubic inches that the car had in the 2009/2010 seasons. This engine had an LS2 block with a 4″ bore and a 4″ stroke.

Since the old engine probably died of oiling system failure (we noted that it had a stock unmodified oil pan) and LS engines have a reputation for oiling issues in serious drift cars and there was no budget for a dry sump, we put a lot of effort into doing the best-wet sump oil system possible that would fit in an S chassis. The S-Chassis requires a front sump and most LS engines are rear sump. We found an oil pan that Canton Racing Products makes just for LS swaps into an S-Chassis.

The Canton pan with wings on the sump has 1.5 quarts more capacity at 6.5 quarts. This is important when running high volume oil pumps. The pan has handy bungs on it for an oil temperature sensor and two turbo drains.

7 comments

Do you think using thermal paste (ala CPUs) would help increase heat transfer on the main bearings?

Might aid in bearing spinning. Usually, engine builders advocate a tight fit on the main saddle for best heat transfer.

it won’t one bit: It will just desolve in oil. Let alone the chunks that get stuck at the oil pickup or the bearings. It just will not work if you really want to remove heat: Graphite paper. Bit that will nog keep the bearing in place. A graphite-silicon based sealer will most likely transfer heat a little less, but will be more resillient to spinning bearings.

Then again: Bearings normally won’t spin that much, unless there are either opposing forces ( flat 4’s for instance) or when the stroke gets to large compaired to the connecting rod. It isn’t so much extra power as it is the rod stroke length.

Mike – any thoughts on using a stock 4.8 crank to reduce the stroke and increase the rod length?

For a road racing or circle track car sure. A drift car needs grunt so I don’t think I would ever destroke one. Mange rod ratio, yes but not destroke. For Dai Yoshihara’s engines, I run a big 4.250 stroke for grunt but also run a super long 6.350 rod with a tall deck block. This gives a stroke to rod length ratio of 1.494:1 which is within the realm of OEM production engines yet still packs a bunch of displacement into a small package. One of our older blocks with a big bore gives us 477 cubic inches!

Mike – What is the best roller rocker / shaft roller rocker option for a stock ls3 head?

For drifting with lower rpm, probably Crower.