Road to Speed Week 2014 Part 1: The AEM Infinity 8 EMS and AQ-1 Data Logger

If this past year's Speed Week taught us anything, it was that Project 240SX LSR's electrical system needed a complete overhaul. Our previous harness had been built in haste during the few days leading up to Speed Week 2012 (read about our Hail Mary story here). At the same time, we also knew that if we were going to top the land speed record we set last year, we needed traction control, data logging, and the ability to control any parameter of the engine whether we were on the dyno or on the dry lake beds of EL Mirage or Bonneville. We found the answer to our needs in the form of AEM's AQ-1 data logger and Infinity 8 stand alone programmable EMS.

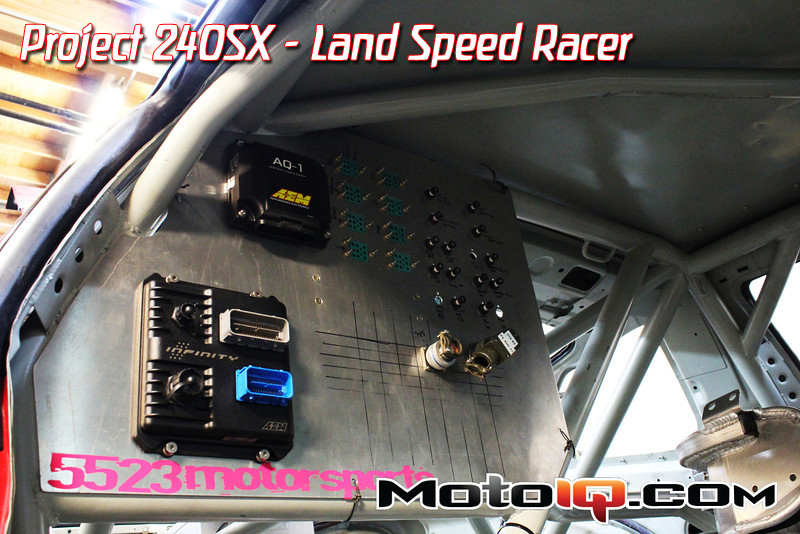

Along with an install of the AEM Infinity 8 EMS, the plan is to have 5523 Motorsports build a race spec wiring harness to compliment our complete electrical system revamp. During the off season, the entire interior of Project 240SX LSR was stripped out including the old electronics board and wiring harness.

The plan is to make a true motorsports grade harness complete with MIL spec and aerospace grade connectors. Unlike the factory harness, each wire will be completely free of any interruptions or random solders and aging crimps. In other words, each wire will be continuous from point to point.

The tightly wound Tefzel wire (bottom) and its silver tinned strands is very apparent under magnification. In contrast, the OEM wire (top) is plain copper and very loosely wound. As a result, the OEM wire cannot handle even close to the same load rating of Tefzel.

The tightly wound Tefzel wire (bottom) and its silver tinned strands is very apparent under magnification. In contrast, the OEM wire (top) is plain copper and very loosely wound. As a result, the OEM wire cannot handle even close to the same load rating of Tefzel.5523 Motorsports plans to construct the harness completely from high quality, light weight Tefzel wire. Tefzel is constructed from fine, high strand count, silver tinned copper strands and is jacketed with tough Teflon, abrasion resistant and self-extinguishing liner. It's used in applications where absolute reliability is an absolute must, such as airplanes.

5523 Motorsports' masterpiece will then be wrapped in DR-25 Raychem heat shrink tubing. Raychem DR-25 was produced specifically as a jacketing for military and motorsports applications by Tyco Electronics. Raychem DR-25 is has long term resistance to high heat as well as caustic diesel, aircraft, and race fuel.

5523 Motorsports' masterpiece will then be wrapped in DR-25 Raychem heat shrink tubing. Raychem DR-25 was produced specifically as a jacketing for military and motorsports applications by Tyco Electronics. Raychem DR-25 is has long term resistance to high heat as well as caustic diesel, aircraft, and race fuel.