,

Our particular traction control strategy will start with the modulation of the throttle plate itself. Instead of relying on my clumsy right foot to perfectly modulate the throttle; instead, we'll be swapping to a drive by wire throttle body from a Nissan VQ35DE and relying on AEM's Infinity 8 unit to control the throttle plate position.

It just so happens that the VQ35DE drive by wire throttle body diameter at 71 MM is the same as the SR16VE N1 throttle body we were previously using. Unfortunately though, the flange pattern is different, requiring John Kuchta of Specialty Cars to weld a new flange on to the intake manifold.

In addition, swapping to the drive by wire throttle body required us to also swap to a 350Z gas pedal. Fortunately, 5523 Motorsports had one of these stashed away for a rainy day. The 350Z gas pedal happens to share the same two bolt flange as the S13. However, the pedal needs to be modified to suit the S13 floor pan. Without bending the pedal's rod or some other type of modification, there is not enough room to sweep the gas pedal through its intended full range of motion.

Post run, it's hard to recall exactly what happened with every aspect of the car. Not to sound corny, but at these speeds you only have split seconds to digest input and react accordingly.

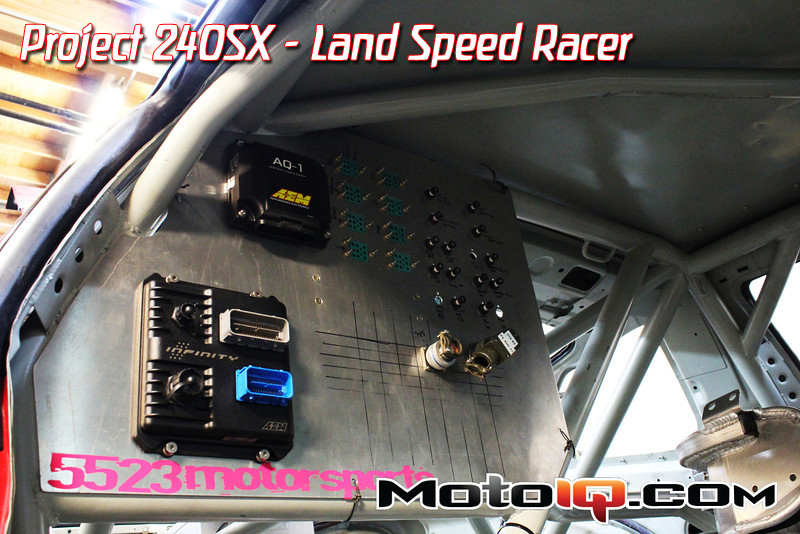

Post run, it's hard to recall exactly what happened with every aspect of the car. Not to sound corny, but at these speeds you only have split seconds to digest input and react accordingly. In addition to enhanced reliability and complete system control, the other major benefit we gained was the AEM Infinity 8's data logging capability. I can't tell you how many times I've gotten done with a high speed pass grateful that both my body and the car are still intact only to be greeted with a hundred questions on how the car was behaving.

Let me tell you, at 186 MPH the last thing I am really worried about is the how much boost the turbo is making, if the car felt like it was squatting too much, or what peak EGTs were. With up to 100 channels (at 200Hz) of data logging capability at our finger tips, we'll be data logging all the key engine parameters… and the crew will have all the data they ever wanted.

Paired with the AQ-1, we'll have enough channels to also log suspension travel through the use of linear transducers (shock pots.) Basically, this will allow the crew to make data-driven decisions during dyno tuning and track testing instead of relying on my butt dyno and borderline senile level memory.