,

After I won the battle with the front pulley bolt, Kyong went at it with an impact gun to disassemble the first donor engine. We were not going to reuse any of the head or main bolts so the impact gun did the job quickly. The goal was to build two engines for WTAC, but we also needed mock up engines for since the car was being built at the same time and for component measurement and design. Many of the components needed to be processed too (e.g. WPC treatment, bore and hone, clearancing, etc.) at the same time so there was a constant flow of VQ components moving through the engineering area in the Cosworth build shop. All in all we had two beat to shit warranty claim VQ35HRs, one brand new VQ35HR from a 2008 Infiniti G35X that Nissan Motorsports supplied us, and another beat to shit warranty claim VQ37VHR that was used strictly for mockup purposes.

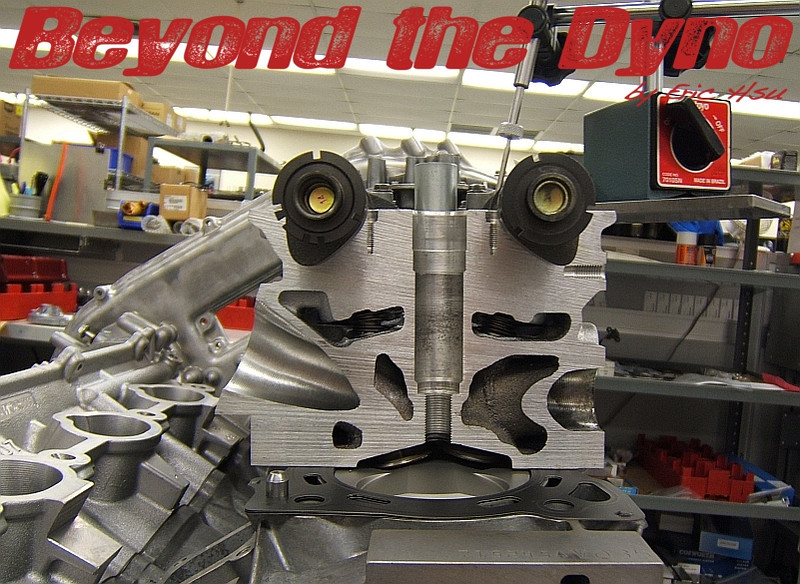

The first thing I did once the crank was out of the engine was to do a visual inspection and check for straightness. The journals and bearings were in amazing shape considering there was cooked oil sludge throughout the engine. This is a little measurement rig that Lew made years ago and is still in use today at Cosworth. Nissan's spec was less than .004″ which seemed a bit excessive to me, but this crank measured at .0008″. I handed the crank off to Magnus who crack tested it in the Magnaflux booths using Zyglo penetrants.

Magnus didn't find any cracks fortunately so he proceeded to balance the crank. Cosworth has a Hines crank balancer that was originally acquired for a NASCAR engine program from back in 2002. It wasn't used for Champ Car or IRL engines since those cranks were balanced at the factory in the UK on a higher end balancer used for F1. The Hines balancer is fine for anything to be used for “lower” revs however. It was fine for the NASCAR engines that spun to 9000rpm so it'll be fine for the ARK Design GTR engines which will have a rev limit of 8500rpm.

A 60° V6 like the VQ/VR family of engines needs to be balanced with exact component weights. These bob weights on each rod journal simulate the component weights for balancing. I chose to stick with the VQ35HR and not VQ37VHR cranks for several reasons: 1) we are using forged factory crankshafts that are made of materials not as strong as motorsport grade billet cranks so the additional 3mm of overlap (between main journals and rod journals) is a huge advantage in strength, 2) factory HR cranks are cheap and plentiful, and 3) we had them. When the car's program progresses further, I will definitely consider a longer stroke forged or billet crankshaft. The reason why I decided to use HR engines is because the main and rod journals are considerably larger than the DE engines which makes the HR crankshafts considerably stronger due to increased overlap (both DE and HR engines have an 81.4mm stroke).

Mag targeted 0.50 gram, but he was able to get it balanced to 0.26g. In a perfect world, the crank would be balanced with the flywheel, clutch, and all fasteners, but this isn't a perfect world. At the time of balancing, we still did not have everything we needed for Tyler to even design the flywheel.