,

Why are Cosworth engines so consistent? One of the reasons is tooling. Here's a tool used for VQ35 piston ring gapping so that every ring is measured at the exact same height in every bore. It's all in the details and while some of these details are simple, they are still important.

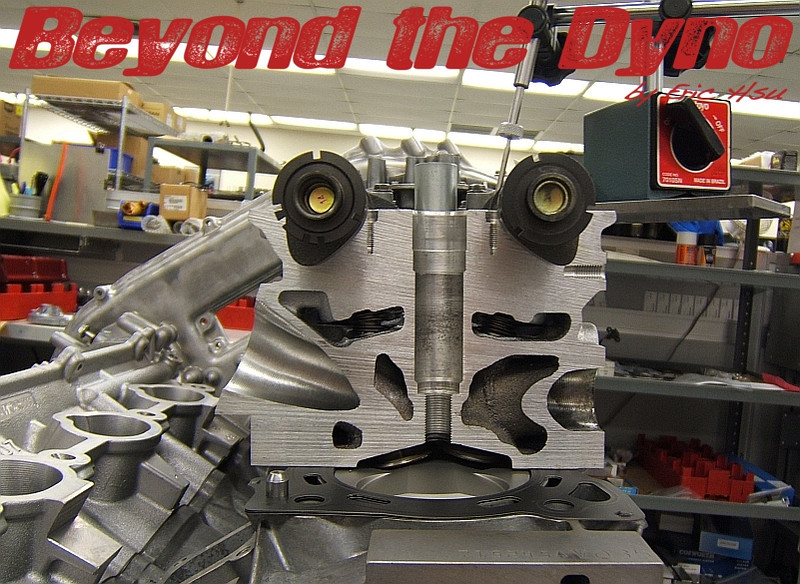

This is a motorized piston ring gapping tool. There's one of these for each engine that is built at Cosworth so that no adjustments are made to adapt it to a ring of another diameter. No time is wasted either with the dial indicator since the gap is right every time. It's all about the details once again.

After gapping, the rings were sent to WPC for treatment specific to piston rings. WPC actually has many different kinds of treatments using different nozzles, medias, blast settings, etc. It's not quite one treatment does it all.

The Cosworth pistons were also WPC treated, but I requested the Xylan skirt coating to be masked off. That Xylan stuff really works. After pistons were removed from Champ Car engines that had 1500 race miles on them, the Xylan was still on there. Not only is that a testament to Cosworth's skirt profile design, but the coating is awesome too. Good enough for Champ Car, good enough for Time Attack.

The ARK Design GTR engines use factory Nissan bearings that have been WPC treated. Luckily the factory VQ35HR bearings are steel backed tri-metal bearings already and not that aluminized crap that a lot of the OEMs are using these days.

Same deal on the main bearings: the factory Nissan bearings are already steel backed tri-metal bearings. They were WPC treated for increased strength and lubricity.