,

I ordered custom rods from Carrillo for the engines. I was able to give Carrillo most of the specs with an estimated cylinder pressure and their engineers were able to run a quick FEA to come up with a design. I put a rush on the first set and they were delivered to my door in three weeks. Carrillo rods are Made in the USA and every single dimension I requested was within tolerance. I love reliable companies that make excellent parts!

It's really strange how Nissan made everything soooo similar between the DE and HR engine, but just SLIGHTLY different. Here you can see the front cover bolts almost all line up with the exception of one bolt per head. Nothing that a little trip to the mill couldn't fix, but it's strange to me that Nissan would even bother changing something as small as that.

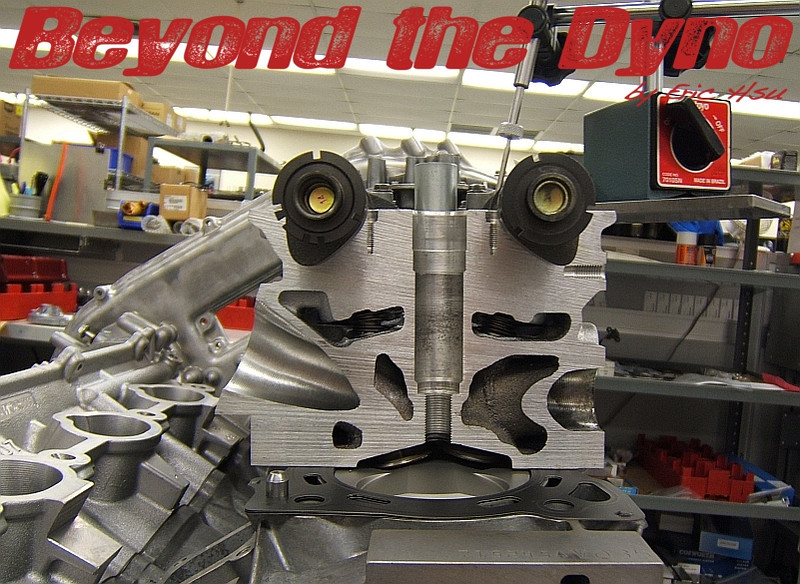

The heads are so similar that it appears like they were cast on the same tooling almost. I know that is not true since the HR ports are completely different than the DE's. In fact, the HR's ports look very much like the VR38's at first glance. That's a DE head on the left and an HR head on the right. There's an oil hole missing at the front from the HR.

The HR cam chain tensioner is on the left and the DE is on the right. Of course I wanted to use the HR tensioners since they were half the weight and aluminum, but the damn bolt centers were different by 3mm so we had to use the DE units. Why did Nissan even change details this small? It's almost like the design engineer took the DE CAD models and modified them and said, “Yeah bro, we have a new engine now.”

Here Katsu puts the left hand cylinder head on engine #1. I chose to use VQ35DE cylinder heads for several reasons: 1) Cosworth had already developed CNC ports, 2) the Cosworth VQ35DE CNC heads had already been used in multiple high revving, high boost engine programs successfully, and 3) I had some spare DE castings sitting around that I had ported. It wasn't quite a simple swap to get to work with an HR block, sprockets, covers, etc. It was almost like an LS/VTEC swap since the variable cam oiling scheme was much improved on the HR engines.

Like I mentioned before, Nissan improved the variable cam oiling massively on the HR engines. Cam oiling is now handled through the front cover and the nose of the cam rather than through the cam caps. All we had to do was plug the holes.

Here Katsu puts a final coat of Royal Purple Max-Tuff assembly lube on the cam lobes and buckets. Even though the factory Nissan buckets are DLC coated, it never hurts to put some extra assembly lube on the followers and lobes. The cams in engine #1 were not WPC treated due to the time frame.