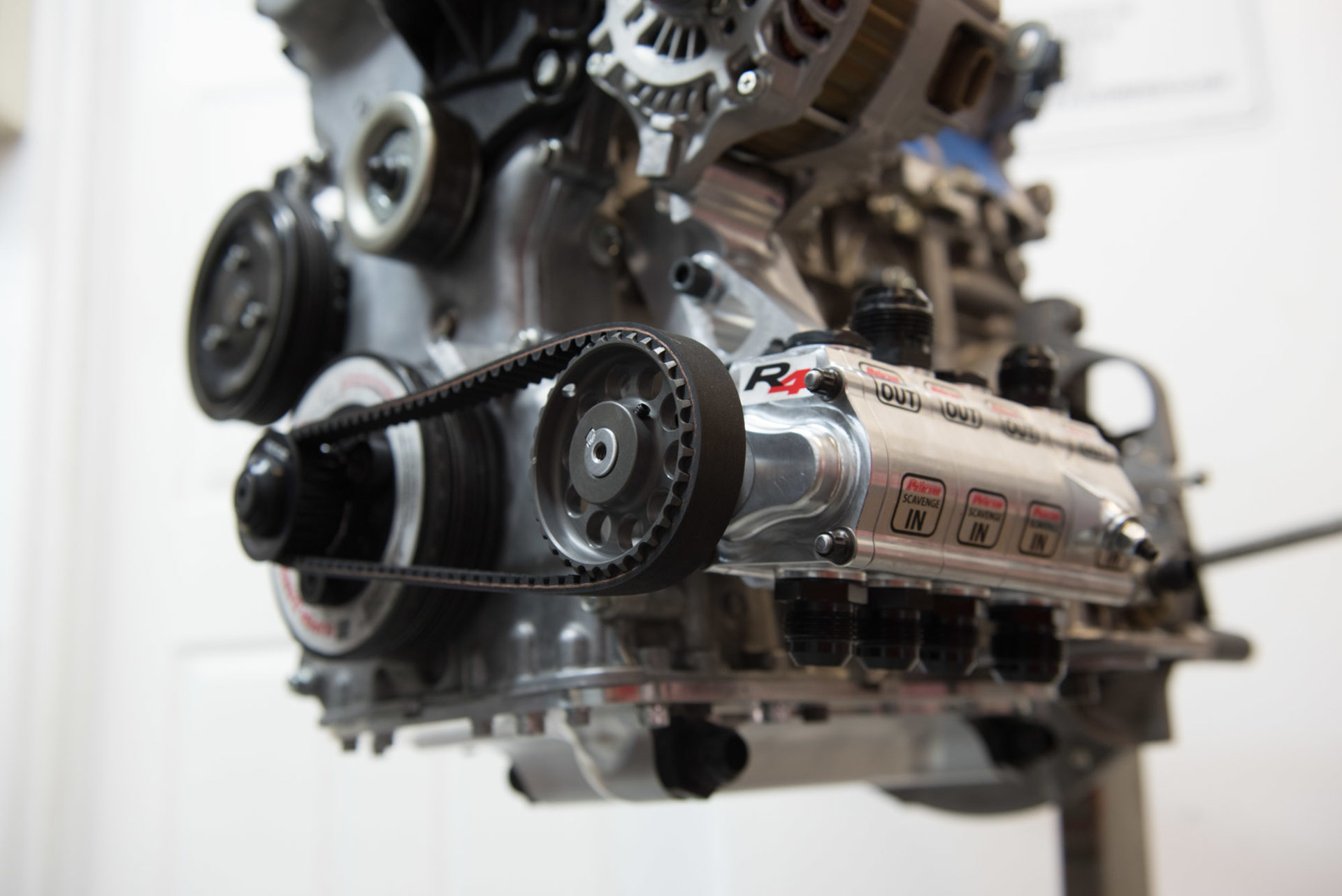

The Peterson R4 dry sump pump we are using has three stages for scavenging (sucking the air-oil mix out of the crankcase) and one pressure stage for sending oil from the tank to the engine’s oil galleys. The R4 has unique 4 lobe twisted vane rotors like a modern supercharger that are very efficient at sucking a mixture of oil and air. This means the R4 can pull a good vacuum in the crankcase which will help improve ring seal and reduce pumping losses. The R4 has an all aluminum construction. Even the rotors are aluminum making this a very lightweight pump.

The World Challenge spec 4B11 with all its accessory drives ready to be dropped into the CSF EvoX. We will be working on a fully built stroker 4B11 while the CSF EvoX does its initial show tour, but you’ll learn about those details in a future article. As you can see above, the FR-S idler pulley fits perfectly on the 4B11 and is orienting our main belt away from the engine mount bracket. Belt tension on the main belt is adjusted with the alternator.

Here is our engine getting hung on the motor mounts before installing the crossmember. With absolutely nothing in the way it was very easy to install the engine, transmission and transfer case into the car assembled from under the car. Not having items like axles or control arms in the way makes installing an engine a breeze! Unfortunately it also means you have all those items left to install.

A closer look at one of the really cool race parts the CSF EvoX came with when it was purchased from GMG – a custom front subframe. The tubular subframe is both lighter and stiffer than the stock stamped steel part. It also gets rid of some of the front suspension’s anti-dive which is desirable in a race car. This will reduce understeer under trail braking and reduce front-end lift and hop under acceleration. Less anti-dive does require stiffer shocks and springs, but we got this covered. If you want a set of these we have the blueprints and can more than likely have them replicated for you. Just click on MotoIQ Garage link at the top of the page to get started.

We replaced the lower engine mount with this solid billet mount by Torque Solutions. The actual mount is urethane so it has a slight amount of give to cushion things, mostly absorb a small amount of high-frequency vibrations. On the custom tubular subframe, the steering rack bolts solidly down with no soft bushings at all. This is good to remove all free play from the steering.

4 comments

Good stuff, but the fumes in the cabin will be unbearable with the catch tank in there. Even with my oil/catch tank mounted in the trunk area (which is sealed off from the driver compartment but not totally airtight) the cabin filled with strong fumes almost immediately so we had to run a breather line from the catch tank vent out the back of the car.

We completely agree and will definitely be moving the breather into the trunk. You’ll see our solutions in later articles when we start getting the car ready for track use.

isn’t that oil cooler about half the size of the stock one? I mean it looks a little bit thicker, but is that enough to make up losing about 1/2 the front surface area?

The stock oil cooler is taller but much more narrow. The CSF core is a lot more efficient.