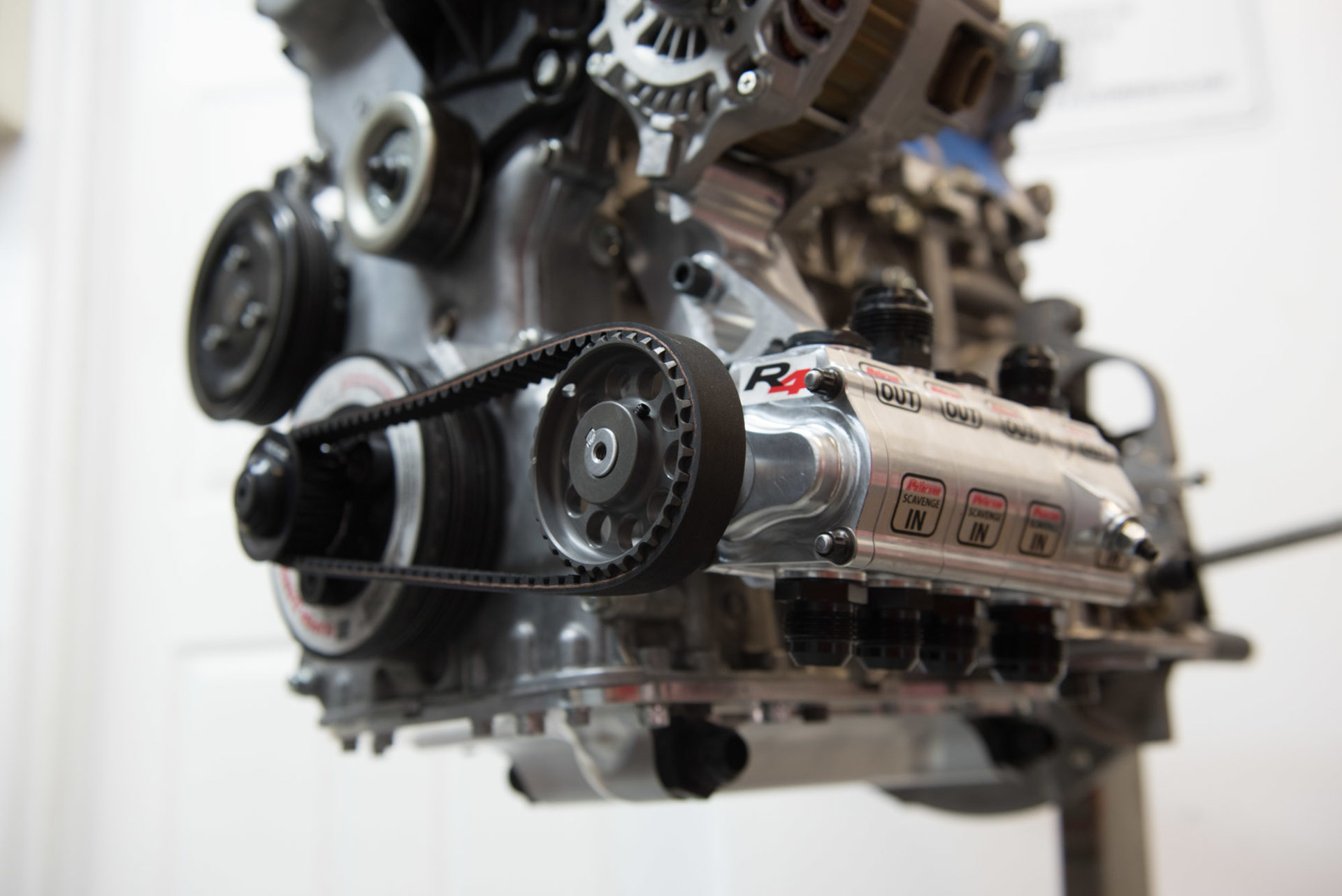

A close up look at the underside of our 4B11’s multi-stage dry-sump system’s XRP plumbing.

Many builders simply pass hoses through holes in the bodywork. If you have been around racecars much, you have probably seen many cases where the sharp edges of the body saw through hoses and cause dangerous leaks. Some builders do a better job and run grommets or pass through bushings. Rywire takes things to the next level and uses XRP bulkhead fittings to properly and safely handle fluid transfer in the EvoX. The holes for the bulkhead fittings are larger than the holes you would need to make if you were to simply run the hose straight through the firewall, but the end result is well worth the extra effort.

This is what the engine side of the firewall bulkhead fittings look like. The bulkhead fittings allow the lines to be terminated with an AN fittings at the firewall, instead of having the lines go through the firewall. With bulkhead fittings it is much easier to perform routine maintenance, as well as more involved tasks like pulling the engine out.

The CSF EvoX’s engine oiling and engine coolant systems are now completely plumbed and we are confident our additions will ensure the stroker 4B11 we will build for its competition days will be able to withstand track abuse. The dry sump system will ensure the engine and bearings will always have a supply of cool and deaerated oil, while the radiator will keep coolant temps under control.

Of course, this is all just hypothetical for the time being. We won’t know for sure until the car gets on track and we really start pushing it. So stay tuned as we continue to walk you through all the details of this amazing build. In the next installment we will be going over the wiring, engine management and data monitoring/logging systems.

4 comments

Good stuff, but the fumes in the cabin will be unbearable with the catch tank in there. Even with my oil/catch tank mounted in the trunk area (which is sealed off from the driver compartment but not totally airtight) the cabin filled with strong fumes almost immediately so we had to run a breather line from the catch tank vent out the back of the car.

We completely agree and will definitely be moving the breather into the trunk. You’ll see our solutions in later articles when we start getting the car ready for track use.

isn’t that oil cooler about half the size of the stock one? I mean it looks a little bit thicker, but is that enough to make up losing about 1/2 the front surface area?

The stock oil cooler is taller but much more narrow. The CSF core is a lot more efficient.