,

Freshly off the trailer, the NX GTi-R was parked in great company at the AES Auto Garage. It absolutely needed to be detailed as it was resting beside Carlos' beautiful and immaculate NX2000 drag car. In the background are two shop cars – a 10 second Civic and a 550+ whp Lexus.

Freshly off the trailer, the NX GTi-R was parked in great company at the AES Auto Garage. It absolutely needed to be detailed as it was resting beside Carlos' beautiful and immaculate NX2000 drag car. In the background are two shop cars – a 10 second Civic and a 550+ whp Lexus.In a perfect world, my timeline would have been met and spring of 2016 would be where the installation of the Haltech Platinum Sport 1000 took place and everything was good to go. You already know that did not happen, so fast forward to May 2017 and all that was needed was some injectors and then tune the Haltec, right? That, of course, is not what happened. With the car sitting for a year, there were a few challenges that had to be overcome. Not to mention that when Paulo, tuner and owner of AES Auto, opened the hood and saw the spiderweb of vacuum tubes and now crooked intercooler piping (with the installation of the Precision 5128 turbo the piping that was nicely set up for the T28 turbo was now looking worse than modern art) – his somewhat OCD soul was shaken to the core. One look and he stated simply that, “This needs to be cleaned up,” and then drew me a couple of sketches of what he already had in mind. All within seconds of lifting the hood.

Plus, there were some maintenance issues that needed to be addressed. While turning left/right the car was literally bucking. I brought this to Paulo's attention, as I had noticed it in Ontario right after the build – to my significant distress as it had not been doing that prior to losing the engine. Was it because it had sat for a year? Was there something else at play? The initial diagnosis was that it was either a bad axle (not so bad) or a bad LSD (quite seriously horrible). Unfortunately, it proved to be the LSD – which was a clutch type Nismo that I had purchased used. Clutch type LSD's for the nineties FWD Nissans are almost rarer than unicorns. However, in this case my buddy Carlos was going a different way with his NX dragstrip monster so his barely used Nismo LSD was available. In fact, it was sitting at AES Auto like it was gift-wrapped for me. No real surprise as Carlos had introduced me to the shop. With likely less than 500 kilometres of use, that LSD is now installed in my B15 transmission. This was without question an unexpected cost financially- but absolutely a necessity. The smooth driving of this Nismo LSD is beyond belief and, even though I had the previous LSD checked over with a fine tooth comb before installation, shows me that something was not quite right from the start with my first aftermarket LSD. Traction has been an ongoing issue and factory LSD's simply could not cope with the increase in power.

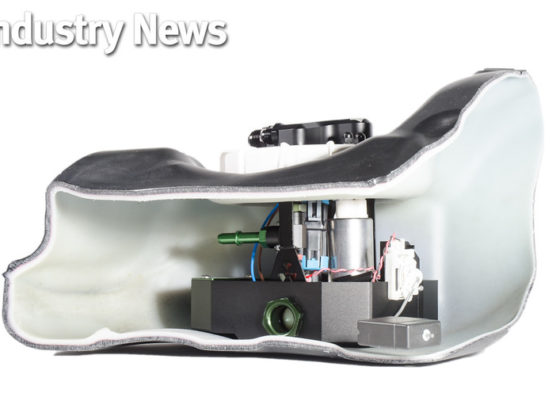

AES Auto was insistent that the vacuum hose issue be addressed before letting the car go anywhere. While I had good intentions, my vacuum line work was far from satisfactory. A Vibrant Vacuum Manifold was a necessity for maintaining good vacuum for the Haltech, the 54c's factory ITBs and Paulo worked wonders at cleaning up my mess.

AES Auto was insistent that the vacuum hose issue be addressed before letting the car go anywhere. While I had good intentions, my vacuum line work was far from satisfactory. A Vibrant Vacuum Manifold was a necessity for maintaining good vacuum for the Haltech, the 54c's factory ITBs and Paulo worked wonders at cleaning up my mess.Another necessity that Paulo addressed quickly was the vacuum tubing under the hood. He pointed out that the Haltech required a consistent vacuum source and, when he realized that the vacuum setup was all my handiwork, he complimented my attempts at ingenuity but then said it all needed to go. Paulo ordered a Vibrant Vacuum Manifold which he attached to the front strut bar. The benefits of this awesome looking Vibrant piece would result in improvements for the factory ITB setup plus improve the boost signal to the Haltech. Paulo also pointed out that the hose that I had been using was not reinforced thus risked collapse at a point where it would surely be inopportune. This was all replaced.

The custom arms are in the center, and I really liked the improvement in handling that they provided. However, AES Auto was concerned that the increase in track width and caster was causing some strain that was affecting my driveline. So, they were replaced with OEM-style equipment.

The custom arms are in the center, and I really liked the improvement in handling that they provided. However, AES Auto was concerned that the increase in track width and caster was causing some strain that was affecting my driveline. So, they were replaced with OEM-style equipment.At this point, you can appreciate that questions about how things could be breaking while the car had been sitting for virtually two years were crossing my mind. This was expanding when Paulo pointed out that the custom front control arms may be causing some challenges, as he thought they put too much forward strain upon the axles. Since they were not legal for some upcoming events that I planned to participate in – but more so because since installation I was always concerned about their strength/integrity – we removed them and went back to a stock setup. I am going to miss the custom units – the additional width/caster really enhanced the cornering experience with this chasis. The downside of going back to stock – the Energy Suspension bushings and Whiteline caster bushings went to another enthusiast years ago. So, the front arms are all stock right now. The upside, the control arms will not be checked for stress cracks or bends nearly as often as the custom units were inspected. There will be some piece of mind – but enhancing the stock units is already percolating. Visions of the Dog II Car's control arms are floating in my head – improved characteristics yet not so drastic as these custom units.

After a failed attempt at getting an alignment, it was time to make some changes. The old arms came out and TurboFX adjustable arms went in. These arms have been needed for years and on my shelf for several months. Notice the background – a Datsun Z car getting a VQ swap, a Nissan GTR, and a very pristine CRX is on the dyno.

After a failed attempt at getting an alignment, it was time to make some changes. The old arms came out and TurboFX adjustable arms went in. These arms have been needed for years and on my shelf for several months. Notice the background – a Datsun Z car getting a VQ swap, a Nissan GTR, and a very pristine CRX is on the dyno. Before spending time on the dyno, the car went out to get an alignment completed. My luck, such as it is, continued with the news being that the rear alignment bolts were seized and the cam-lock tabs were broken/bent and would need to be repaired. The great thing about seized bolts is that your frustrations can be washed away while carefully smashing the offending bolts with a massive hammer. Of course, replacement bolts were easily an overnight order from Nissan – if I still lived in Ontario. Since the west coast is now home, it was a week. And, even then two never made it in time. Fortuanately, those two long bolts were not siezed and were in mint shape and ready for reuse. The stock arms and ES bushings came out – they have had many years of use – and custom control arms from TurboFX went in their place. These beefy units were powder coated by Stripping Technologies before I left Ontario and will provide significantly greater adjustability. If only TurboFX made front control arms too! Thanks to Can-Alignment for providing me with alignment specifications to use as a benchmark and starting point in a new track environment. Huge thanks to Dales Auto in Surrey for fitting me in on short notice and doing spectacular work on the setup.

The TurboFX arms were powder coated by Stripping Technologies, who do all of the work on James Houghton's K-Tuned Type R and Chris Boersma's newly wrapped K-Tuned Civic. Please note that the arms are not yet torqued into place.

The TurboFX arms were powder coated by Stripping Technologies, who do all of the work on James Houghton's K-Tuned Type R and Chris Boersma's newly wrapped K-Tuned Civic. Please note that the arms are not yet torqued into place.