,

We also applied oil to the outer oil pump rotor to act as pre lubricant on engine startup.

We also applied oil to the outer oil pump rotor to act as pre lubricant on engine startup.

The oil pump gears are dropped into the housing.

The housing is assembled. Now we have a much stronger and relaible oil pump! One weak point down!

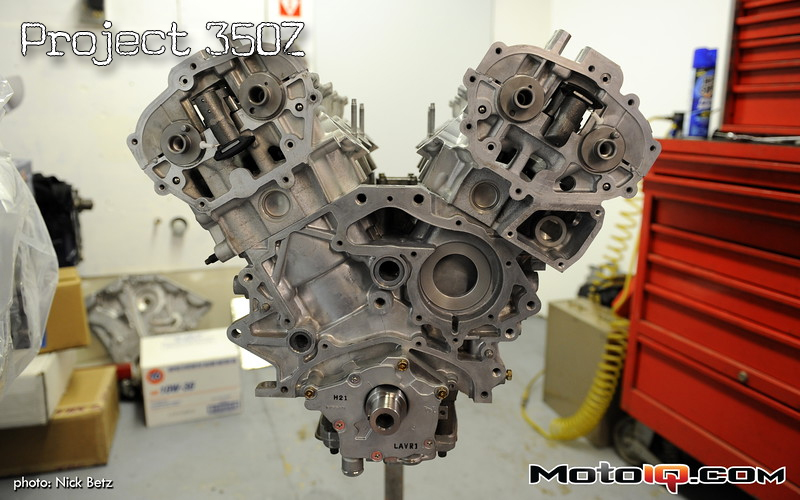

The housing is assembled. Now we have a much stronger and relaible oil pump! One weak point down! Our heavy duty tri Metal King XP racing bearings are laid into the main saddles of our VQ block. The block has been cleaned and the deck has been verifed for straightness. The black top layer is King’s unique overlay which has a high copper content and a nano scaled hardening process. The black overlay gives a King bearing over 20% more load bearing capacity compared to a conventional soft overlay.

Our heavy duty tri Metal King XP racing bearings are laid into the main saddles of our VQ block. The block has been cleaned and the deck has been verifed for straightness. The black top layer is King’s unique overlay which has a high copper content and a nano scaled hardening process. The black overlay gives a King bearing over 20% more load bearing capacity compared to a conventional soft overlay. The King XP main bearings are also installed into the main caps after thoroughly cleaning the cap, block saddles and bearing backs to make sure they are totally clean and dry. This is essential for accurate clearance measurement and bearing crush.

The King XP main bearings are also installed into the main caps after thoroughly cleaning the cap, block saddles and bearing backs to make sure they are totally clean and dry. This is essential for accurate clearance measurement and bearing crush. The main bearing caps and main cap girdle are installed and torqued down. Now the bearing bores are measured in three places with a bore gauge to confirm that the bore is perfectly round and the diameters are recorded. This enables us to confirm the main bearing clearance.

The main bearing caps and main cap girdle are installed and torqued down. Now the bearing bores are measured in three places with a bore gauge to confirm that the bore is perfectly round and the diameters are recorded. This enables us to confirm the main bearing clearance.