,

The main caps bolt are torqued down then tightened to angle to set bolt stretch.

The main caps bolt are torqued down then tightened to angle to set bolt stretch. The diverter wall of the cooling passage has been lowered 12mm so we can use the 3rd generation VQ35HR head gasket. The VQ35HR gasket changes the water flow pattern through the head to cool the exhaust valve area first. This greatly helps the engine’s cooling and reduces the chances of detonation.

The diverter wall of the cooling passage has been lowered 12mm so we can use the 3rd generation VQ35HR head gasket. The VQ35HR gasket changes the water flow pattern through the head to cool the exhaust valve area first. This greatly helps the engine’s cooling and reduces the chances of detonation. We also install ARP head studs at this point. ARP head studs are made of high strength 8740 chromoly steel. The ARP head studs also have rolled asymmetrical J-form threads and a reduced center diameter to decrease stress risers. ARP head studs have high quality forged nuts and precision ground and hardened washers from the same material for accurate torque and positive retention.

We also install ARP head studs at this point. ARP head studs are made of high strength 8740 chromoly steel. The ARP head studs also have rolled asymmetrical J-form threads and a reduced center diameter to decrease stress risers. ARP head studs have high quality forged nuts and precision ground and hardened washers from the same material for accurate torque and positive retention. The original VQ35DE head gaskets were two layer MLS steel. They were prone to leak. The new VQ35HR head gaskets have a third thin steel stopper layer around the cylinders to increase clamp load and to improve sealing around the cylinder. The new gaskets improve sealing and cooling at once.

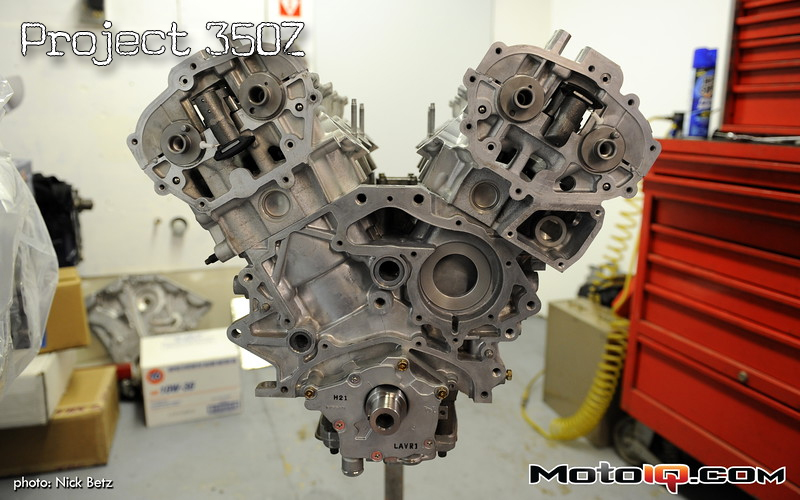

The original VQ35DE head gaskets were two layer MLS steel. They were prone to leak. The new VQ35HR head gaskets have a third thin steel stopper layer around the cylinders to increase clamp load and to improve sealing around the cylinder. The new gaskets improve sealing and cooling at once.Our heavy duty bottom end is now complete, stay tuned, in our next segment we will finish the engine assembly and have Church Automotive Testing tune the ECU with Up Revs system for high compression with 91 octane pump gas.