To make my low-mount turbo setup work, I would need to relocate the oil filter to make space for the turbo compressor inlet pipe. Of course, that means mounting the oil filter somewhere else. I also planned on retaining the stock oil cooler instead of my previous oil cooler setup. Personally, in order to make a reliable 500hp S2000 track car that can be lapped endlessly, I think it would require too many extensive modifications. So, the car will be more like a qualifying car, where it’ll be good for a hot lap or two before needing to back off.

https://photos.smugmug.com/photos/i-kkzVjbM/0/XL/i-kkzVjbM-XL.jpg

I did upgrade the SPAL fan mounting with your prodding. These SPAL fan bracket straps are only about $10 for four of them. This setup looks a little weird to me because I had the oil cooler located here for so long. When I upgraded to the new thinner Koyo radiator, Project S2000 AP1 inherited my old Koyo radiator and Earl’s oil cooler setup.

I used nylon lock nuts to make sure nothing shakes loose. I may go get longer bolts though because it’s best practice to have a couple threads extending past the nut.

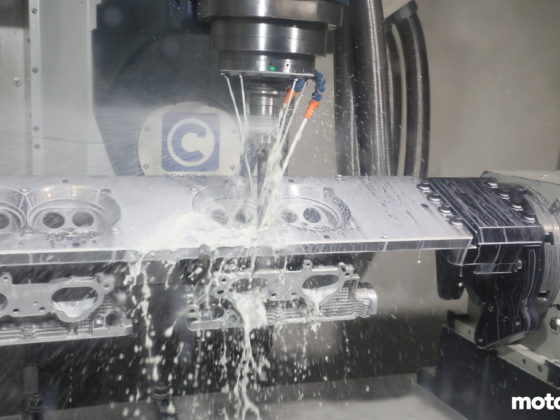

You can see here how the oil filter would be in the way of the compressor inlet pipe to the Garrett G25-660.

I had the pre-oil cooler setup on the car with the ARK Design sensor sandwich plate for the MFD2 stacked between the stock oil cooler and oil filter. That is a lot of stuff in the way of the future compressor inlet pipe that needs to get moved.

In case you were wondering this is how much oil stays in the filter when you remove it from the stock location.

8 comments

Do you think a proper shroud on the radiator for the fans would improve the efficiency of your setup? Very similar to this: https://www.summitracing.com/parts/der-16927

The fans are only needed in low-speed operation. Once at speed, there’s enough airflow that the fans are not required. At speed, those shrouds just become a flow resistance and reduce cooling. That particular shroud you linked does have a couple flaps that open up when there’s enough airflow from vehicle speed. In my opinion, shrouds should only be used when the heat exchangers are placed in locations where they don’t get significant direct airflow. So one place shrouds are commonly used is on off-road racing trucks were the radiators are placed behind the cab.

Killerbee catch cans are cool and all, but I can’t comprehend paying $375-$420 bucks for them. Especially when there are alternatives that work flawlessly for $150 or less.

They do command a premium for their billet ones. They have been developing lower cost alternatives like the black one. I’m really digging this new compact AOS which should work well in my application. It seems modern cars with DI systems have much less oil collected in catch cans. The S2k does generate a fair amount, but because I’m planning to constant drain, I don’t really need much storage volume at all.

back into the oil pan? I heard its not a good idea to do that cause it also collects moisture, any truth to that?

I think it depends on the particular vehicle and how their PCV setup is configured. As a casual observation, basic inline and V engines, it’s pretty simple. Flat engines liked in Subarus and Porsches seem to have more complex systems which are maybe more prone to condensation. On my S2k at least, I only ever got significant oil in my catch can from track use and it came out looking like regular oil, no milky stuff. At that point, the oil is hot enough to boil off any water.

https://motoiq.com/project-s2000-part-22-testing-new-goods-and-more-intake-mods/5/

It’s hard to believe the Improved Racing remote filter mount doesn’t have dedicated additional ports for sensor fittings, especially given the price. Using that ARK adapter adds potential leak paths and bulk. It may be best to utilize the unused ports of the Improved Racing remote filter mount and install adapters for the sensors. You may be able to drill and tap into the top side as well.

Will running the catch can return line into your turbo drain line overwhelm the turbo drain? You may need to increase the diameter of the return after the tee.

On the remote filter mount, where I’m using two plugs, you can get the plugs with 1/8 NPT sensor ports. The sensors that came with the ARK Design MFD2 are most likely 1/8 BSPT. I decided to leave well enough alone for two reasons: I’ve been running the sandwich plate with sensors for over a decade with no issues and I think it will give me a bit more flexibility in mounting. I’m already claiming space for the oil filter and cooler, so stacking the sensor sandwich plate just takes some more space in the same direction. If I add the sensors to the remote filter mount, they will stick out the opposite side of the oil lines, increasing the footprint. For the turbo oil drain, I was planning to use a -10AN line, so it should be plenty big. I guess I haven’t shown it yet, but the timing chain cover was already tapped and welded with a -10AN fitting for the turbo oil drain return.