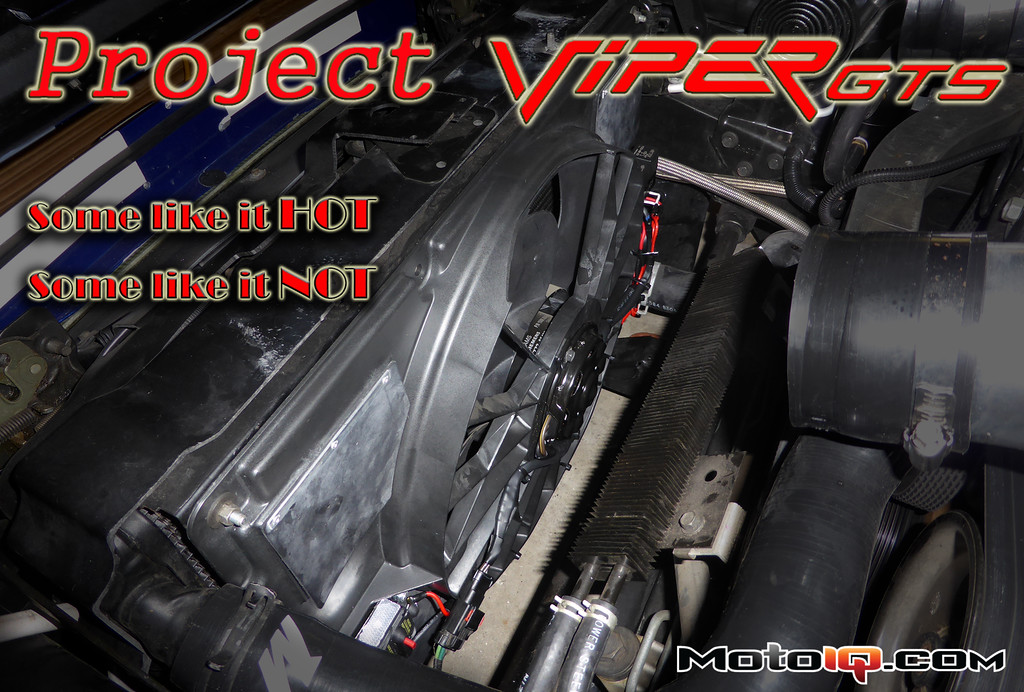

We applied Thermaflect cloth on the inside face of the shroud to further reflect heat off of the shroud where the electronics are mounted.

After everything is mounted, it’s time to do some wiring; the right way.

The 10 gauge MIL-spec wiring should be more than sufficient to carry the load of the new fan. Wrapped in ¼” chemical-resistant Raychem shrink tube and sealed from the elements with a small strip of adhesive-lined shrink tube (that melts to a hard plastic-like seal), we stripped the wire to prepare it for our ring terminals.

Step 1:

Step 1:

Using the right tool for the job, our Paladin crimper uses the proper amount of force to secure the wire without breaking the strands.

After being crimped, the ring terminal is ready to be soldered.

Step 2:

Step 2:

In addition to the crimp, we further improve the electric conductivity and durability of the connection by soldering the wire to the ring terminal.

Step 3:

Step 3:

If the crimp or solder wasn’t enough, to top it all off we used adhesive-lined shrink wrap to isolate the connection from the elements and to take any stress off the crimp and solder and distribute it to the wire itself.

Doing things right always takes more time and any of the three processes could have held the connection in place by themselves. Having done all three, it is nearly fail-safe. There’s a reason why motorsport-grade wiring harnesses costs thousands of dollars and no job is too small or insignificant to do it right.

10 comments

Radiator fan wiring upgrade they auxiliary relays what wires output to the fan either number or color it’s not clear thank you for your help

Have a customer with a 96 wanting to do this upgrade to his cooling system, any idea where the cooling fan may be available?

That’s weird. I’ve always been taught to crimp ring terminals on the cut side, so it forms a B-type crimp that secures the wire. Well, whatever works!

good evening i have a 1999 viper GTS and i just got the radietor from you do u by any chance sale the hole kit for the fan to make it work better please let me know so i can buy ti thanks

need to but a water pump for 1997 dodge viper. please call me 505-316-0182

surffun1915@aol.com i did evething u did but when it hit 190 the fan starts 5 min later the 60 amp trips fan goes out car will get hot i had to wait to cool to re-set the 60 amp ignition protector

What temp does the fan kick on? Did you change the low or high speed fan temp threshold by flashing your ECU? If you’re tripping the 60A circuit breaker, then you need to troubleshoot and find what is causing the excessive amp draw.

Is the Bosch relay with the 332 209 151 number the same relay? Stats look similar to the one you have installed

Those appear to be 30A relays vs the 50A relay that I used. I would recommend using the part number for the 50A relay.

can u send me more detail about the wires evething look nice but i can not see every cable where they go to make shure i conected right i need the order or a better pictures can u send me a diagram i got all the parts thanks