,

|

| Vibrant sent us several big boxes of fabrication supplies. All stainless tubing for the exhaust, all aluminum tubing for the charge pipes, all of our flex joints, V-Band clamps, silicone couplers, turbo heat shields and T-Bolt clamps were supplied by them as well. |

|

| Here is a merged Vibrant Y shaped merge collector, some tubing and a Turbosmart Compgate 40 wastegate. |

|

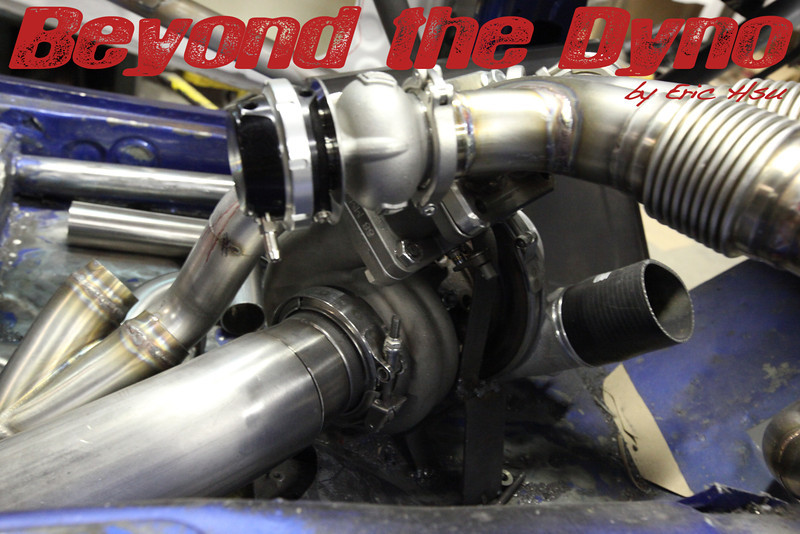

| Trying to figure out where to locate the Turbosmart wastegates was an issue. We wanted to keep everything low in the chassis but stuff had to be placed for ease of maintenance and for a good flow of gasses from the wastegate. We are running a twin scroll EFR turbo so we need twin wastegates. |

|

| Pete mulls over some things on wastegate placement. The Turbosmart wastegates are very compact which aids packaging. We are building an insulated box around the turbo that we call “The Oven” to protect the driver from excessive heat and noise. Having the turbo inside the car helps weight distribution and lets us build a direct, straight smooth flowing and simple exhaust which should help performance. In this case, it is perfect that the BorgWarner EFR turbos are burst tested to retain any potential wheel or blade separation incidents. It is unorthodox but we think it will help handling, make maintenance on the car easier and help improve aerodynamics. |

|

| We ended up placing the wastegates on either side of the Y-Pipe right before the exhaust housing. Eric instructed Pete to ensure the wastegate entries were angled the way they are to ensure waste gas flow. Now it was Minh fabbing up the wastegate dump tubes. This car was built by part timers and volunteers tag teaming constantly! |

|

| We have started to tack up the wastegate dump tubes and are starting to form up the exhaust. The exhaust is going to be sunk into the floor for aerodynamics. This will allow us to run a flat floor to feed the rear diffuser with a cleaner source of air. |