,

Next the oil scraper rings are spiraled into place. Spiraling is the safest way to install rings with the least risk of breaking them or scratching the piston.

The compression rings are not spiraled in. It is very important to put the proper side of the rings up and to put the right ring in the right groove.

The piston and rod is now ready to install. Repeat on the other rods and pistons.

The rod bearings are installed into the rod and the rod cap after cleaning them much like the main bearings. Next the rod bolts are lubricated with the supplied assembly lube. This is a very important step for proper torque..

The rings are lubricated.

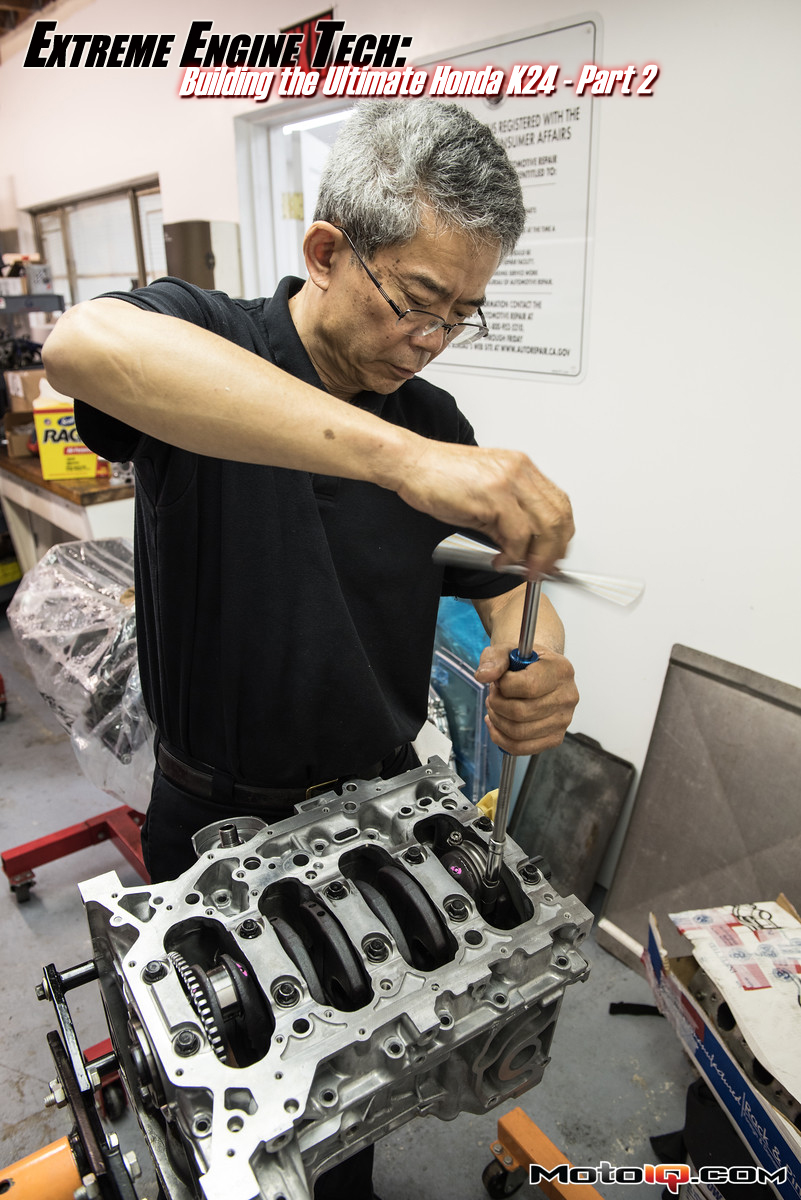

Next a ring compressor tool is installed over the piston to squish the rings down so the piston can be inserted into the bore without snagging the rings.

1 comment

Cool to see you guys using the newer k24 blocks, wished you used the head too because I wanted to see what works. I’m building a k24z3 and saw that you cut off the balance shafts, by retaining the stock oil pump system means I can still use the bottom location oil filter correct?