Here is Dai’s very first pass with the car for the 2019 season at the Long Beach round. The car is very stable and much more predictable and easy to drive than previously. I find it amazing that the pros can just go out and drive so well cold from their first pass on a difficult unforgiving and narrow course like Long Beach.

So the car now has quite a bit of potential and is working very well. The only thing is that the cars base setup is now very different than before so our notes from the past few years are going to be partially worthless! Regardless, this is a great example of how 3D printing can greatly speed the design, production and testing process of parts with complex geometry.

7 comments

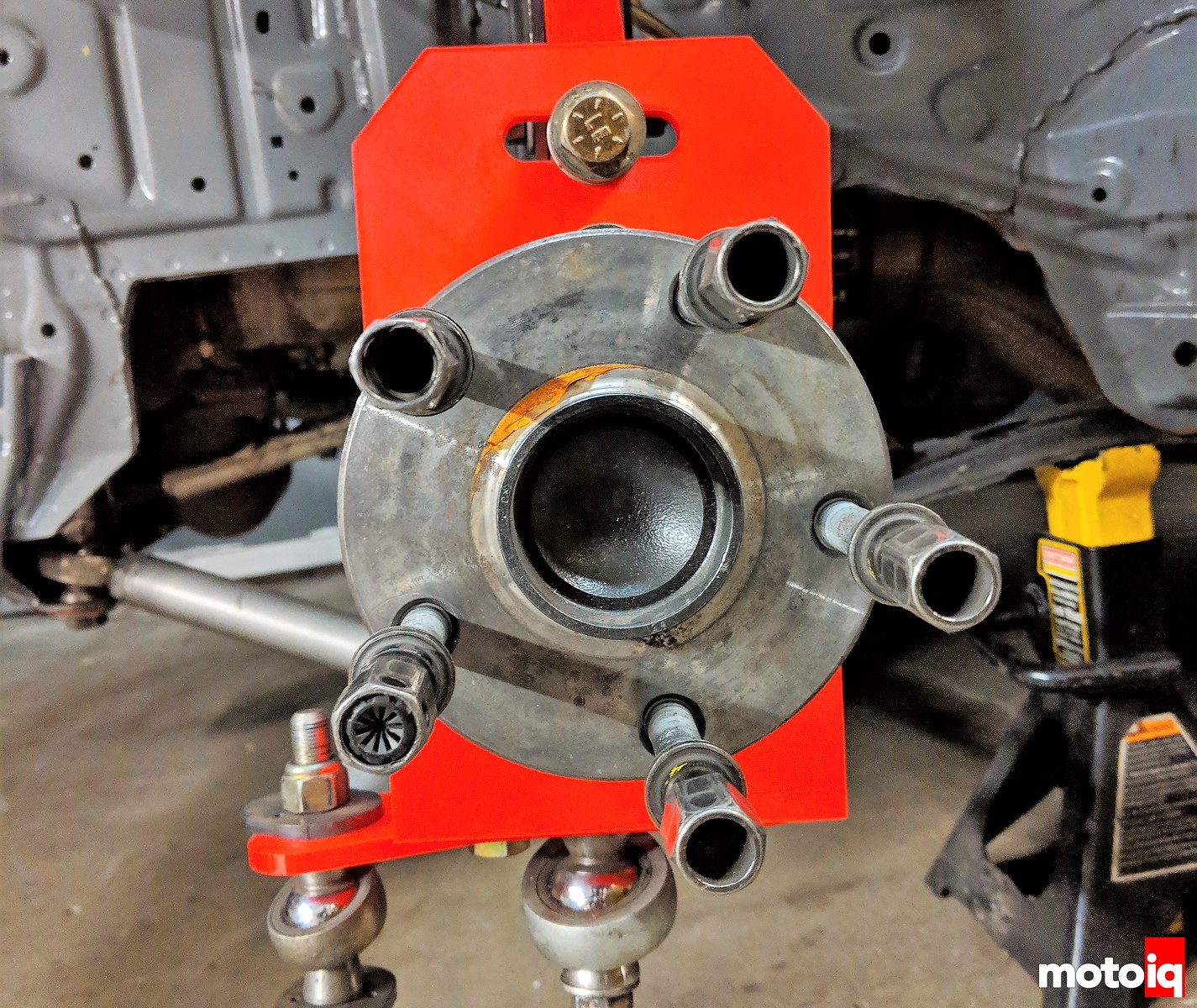

Nice setup, but just wondering about one thing: Why all the holes inside of it all? Wouldn’t it just be easier to make it in a flat panel without the holes? It’s probably done to reduce weight without a big compromise to strength, but i can imagine rubber debris is getting slewn in there?

Some of it is to reduce weight and also to get to the bolts holding the hub in. Debris can fall out the bottom easily and we have not had a problem with that issue. We design it to be pretty strong and the suspension links are the fuse in the design. We have stress riser failure points built into the arms so they will fail before the upright and chassis. This way we can repair the car in the allotted 5 minutes.

Ah right! I couldn’t see there where bolts inside, but that makes sense. Good thinking about the arms. Way less hassle to replace!

Cool. This validates my ideas on optimization of a drift car. Namely, the reduction of caster and Ackerman.

I learned a long time ago that caster (and dynamic camber gain) as the ‘secret’ to good turn-in ability. When you analyze your own footwork, you can see that your ‘outside foot’ digs in on the inside edge to initiate a turn. The same thing needs to happen with the tire footprint. The tire needs dynamic negative camber gain on the outside wheel, in order to initiate a turn to the inside. You can do this with SLA suspension, or by dialing up the caster on a strut equipped vehicle.

But, the same thing that helps a race car, works against a drift car, specifically because of the extreme steering angles. The driver has to fight against the wheel when the caster and Ackerman are high. Also, the drift car isn’t ‘turning’ in the conventional way, so you have to undo what works on one car, in order to optimize the other.

That is not how it works.

BTW, nice part design.

Totally unrelated to the knuckle design (which is really awesome), I noticed that you’re using the Hyperco articulating spring perch. Did they make a tangible difference? I hear they need frequent rebuilds.